215626 119 Revision A

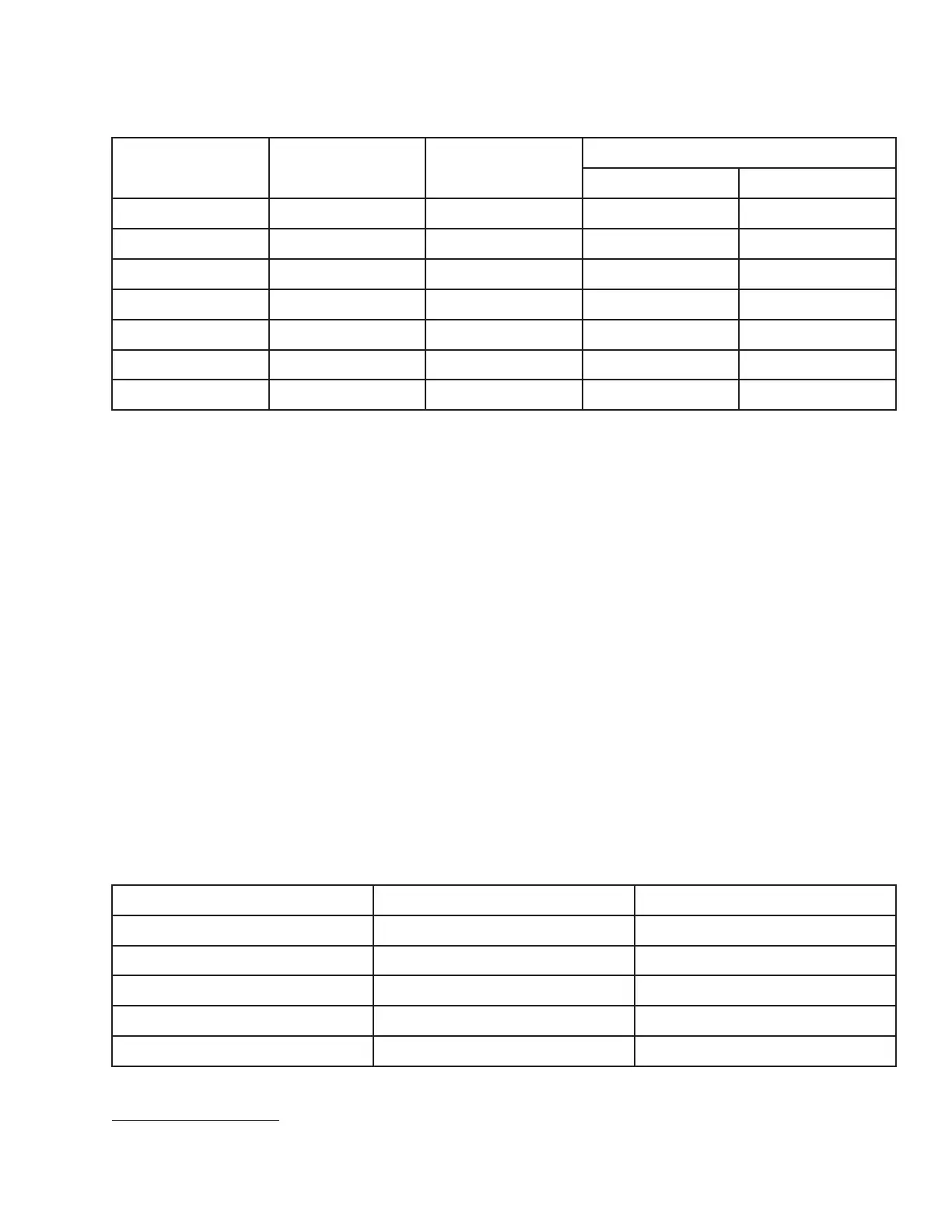

Table 6.13 O-Ring Face Seal (ORFS) Hydraulic Fittings (continued)

SAE Dash Size

Thread Size (in.) Tube O.D. (in.)

Torque Value

14

Nm

lbf·ft

-10 1

5/8

80–88 59–65

-12

1 3/16 3/4

115–127 85–94

-14

Note

13

7/8

––

-16

1 7/16

1 150 –165 111–122

-20

1 11/16 1 1/4

205–226 151–167

-24 1–2

1 1/2

315–347 232–256

-32

2 1/2

2 510 –561 376–414

6.1.8 Tapered Pipe Thread Fittings

Torque values are shown in following table below.

Assemble pipe fittings as follows:

1. Check components to ensure that the fitting and port threads are free of burrs, nicks, scratches, and any form of

contamination.

2. Apply pipe thread sealant (paste type) to the external pipe threads.

3. Thread the fitting into the port until it is hand-tight.

4. Torque the connector to the appropriate torque angle. The turns from finger tight (TFFT) and flats from finger tight

(FFFT) values are shown in Table 6.14, page 119. Make sure that the tube end of a shaped connector (typically 45° or

90°) is aligned to receive the incoming tube or hose assembly. Always finish alignment of fitting in the direction of

tightening. Never back off (loosen) the pipe threaded connectors to achieve alignment.

5. Clean all the residue and any excess thread conditioner with an appropriate cleaner.

6. Assess the final condition of the fitting. Pay special attention to the possibility of cracks to port opening.

7. Mark the final position of the fitting. If a fitting leaks, disassemble the fitting and check it for damage.

NOTE:

Overtorque failure of fittings may not be evident until fittings are disassembled.

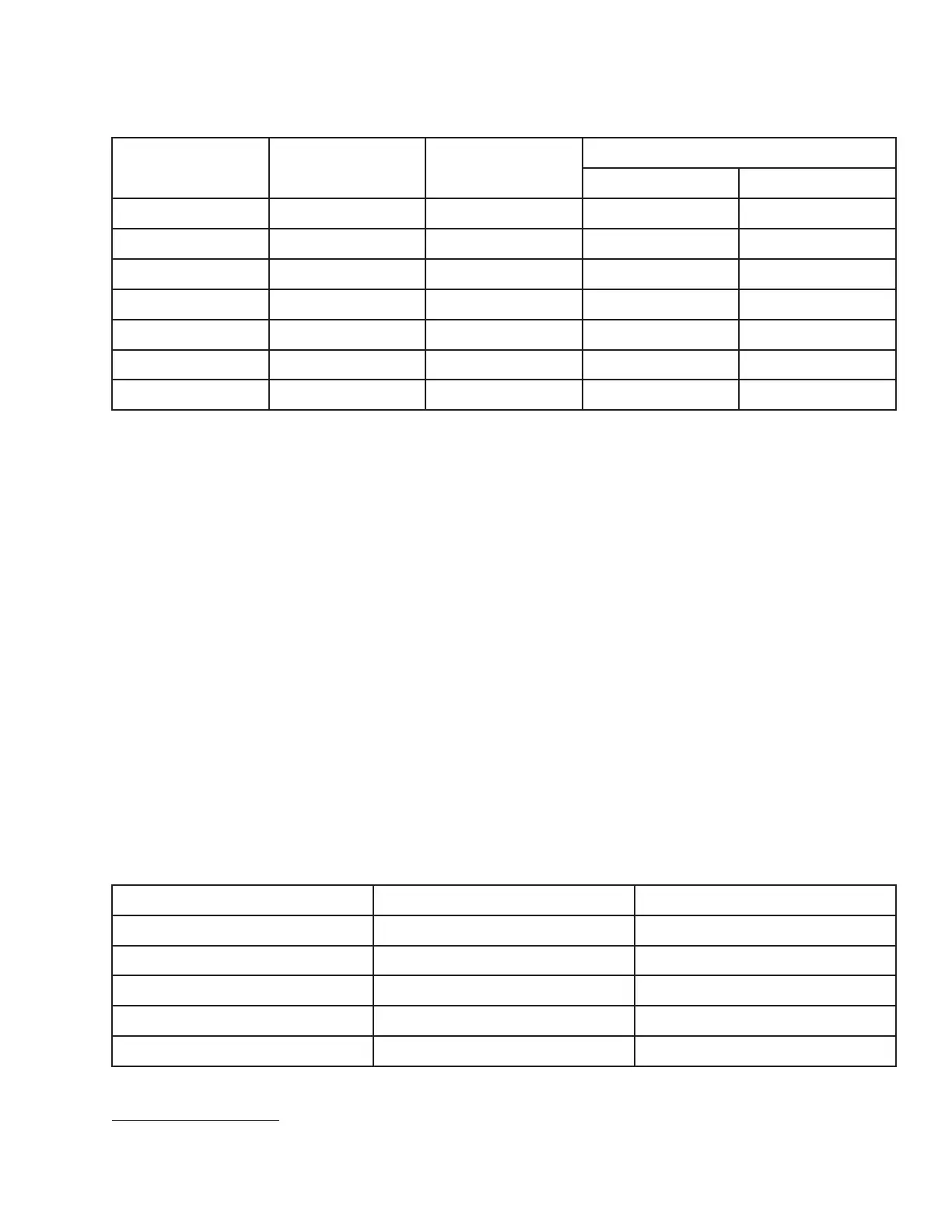

Table 6.14 Hydraulic Fitting Pipe Thread

Tapered Pipe Thread Size Recommended TFFT Recommended FFFT

1/8–27

2–312–18

1/4–18

2–312–18

3/8–18

2–312–18

1/2–14

2–312–18

3/4–14

1.5–2.5 12–18

REFERENCE

14. Torque values and angles shown are based on lubricated connection as in reassembly.

Loading...

Loading...