What to do if the float indicator is not moving on my MacDon D1 Farm Equipment?

- AAlex GarciaAug 1, 2025

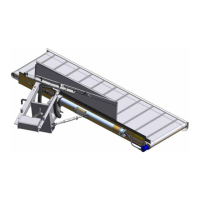

If the float indicator isn't moving, here are several things you can check: * Inspect the pulleys and replace them if needed. * Replace the cable. * Clear out any material that may be obstructing movement. * Install cable ties around the rubber sheath and cable to secure it. * Replace the spring. * Check for a seized pin in the bore; clean if necessary, then replace the cotter pin. * Adjust the voltage range. * Replace the sensor.