215184 519 Revision A

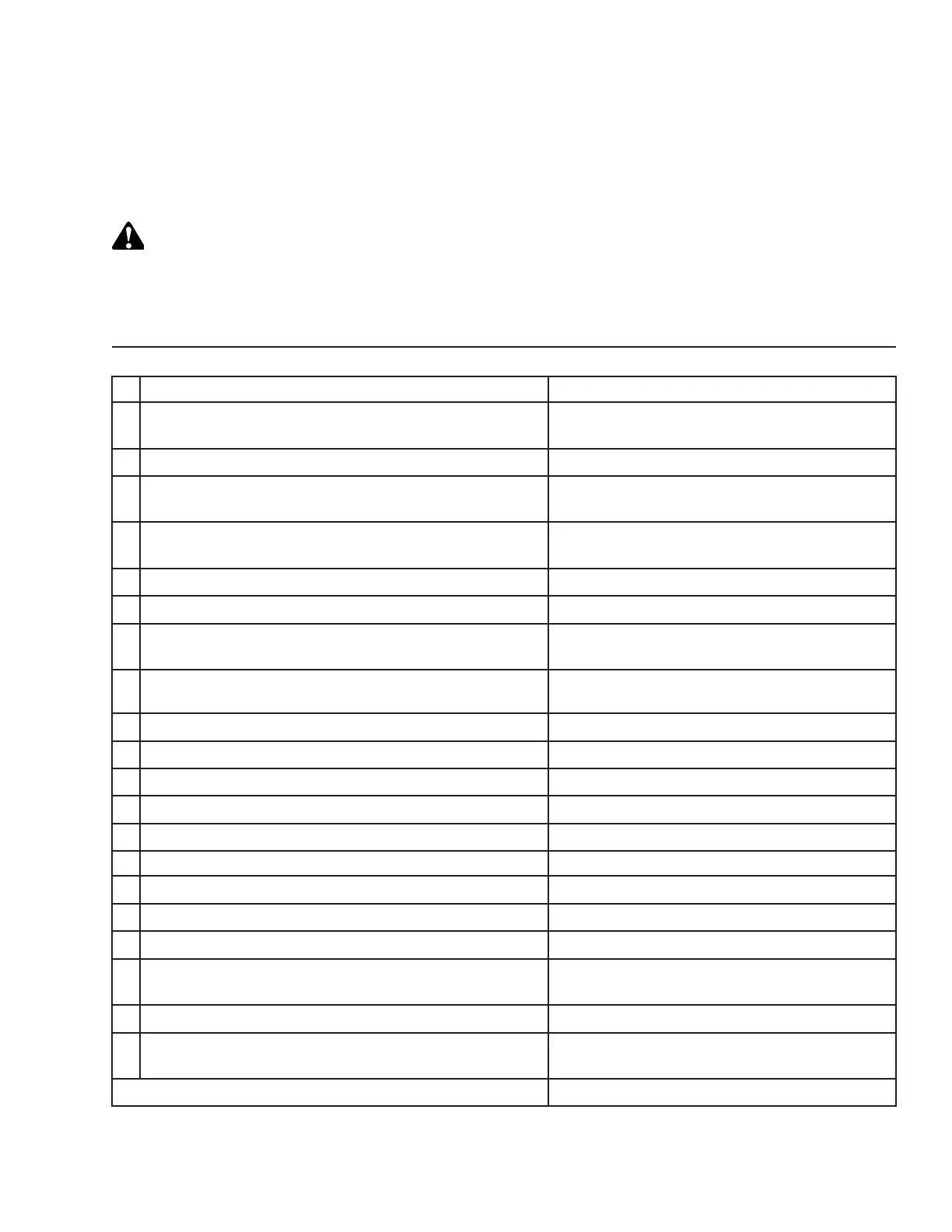

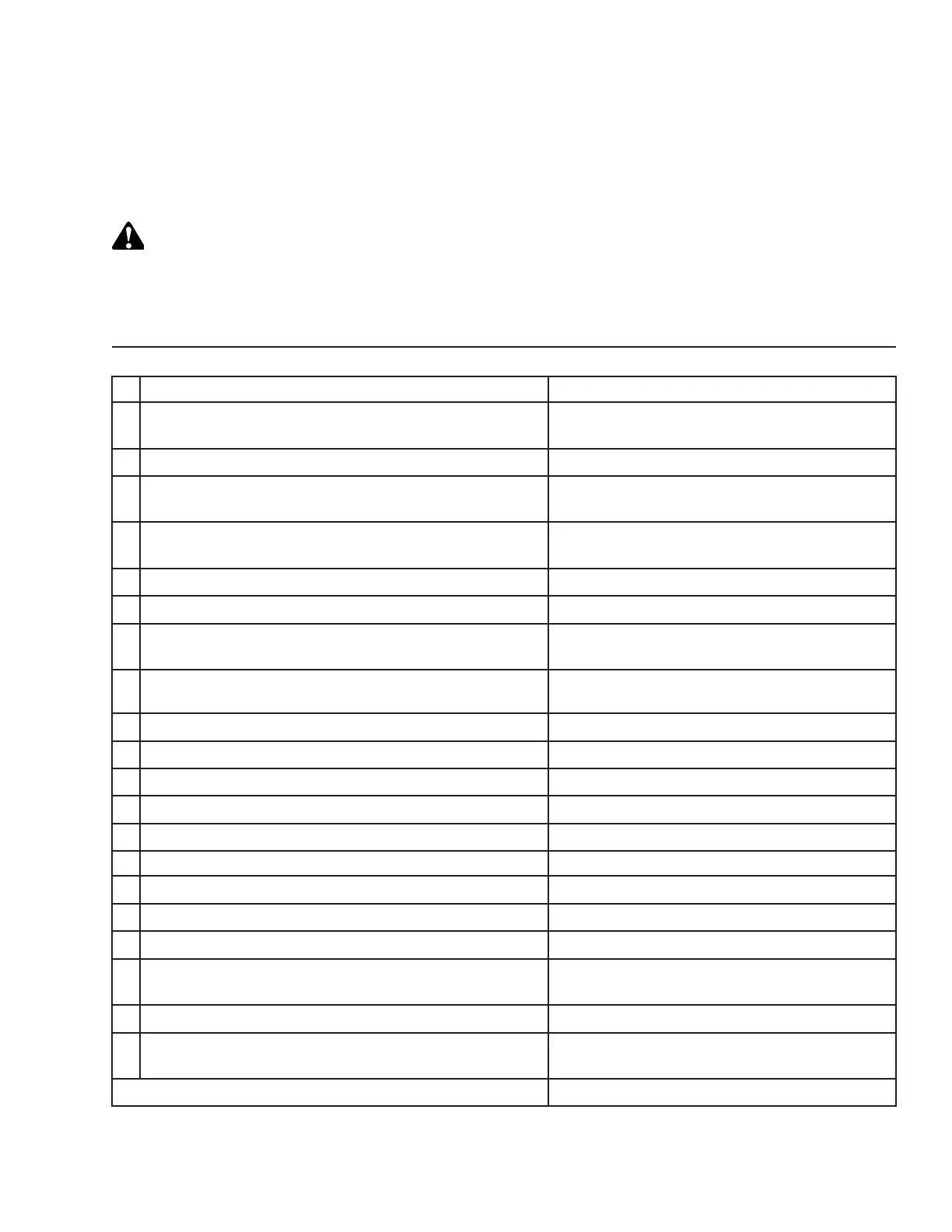

Predelivery Checklist

Perform these checks and adjustments prior to delivery to your Customer. Adjustments are normally not required as the

machine is factory-assembled and adjusted. If adjustments are required, refer to the appropriate page number in this

manual. Ensure that the completed Checklist is retained by either the Operator or the Dealer.

CAUTION

Carefully follow the instructions given. Be alert for safety related messages that bring your attention to hazards and

unsafe practices.

Header Serial Number:

Float Module Serial Number:

üü

Item

Reference

Check for shipping damage or missing parts. Be sure all

shipping dunnage is removed.

—

Check for loose hardware. Tighten to required torque.

12.2 Torque Specifications, page 506

Check tire pressure (Transport/Stabilizer Option).

8.1 Checking Tire Pressure – Transport and Stabilizer

Wheels, page 257

Check wheel bolt torque (Transport/Stabilizer Option).

8.2 Checking Wheel Bolt Torque – Transport and

Stabilizer Wheels, page 258

Check knife drive box breather position.

8.3 Checking Knife Drive Box, page 259

Check knife drive box oil level.

8.3 Checking Knife Drive Box, page 259

Check float module gearbox oil level.

8.4 Checking Oil Level in Header Drive Gearbox,

page 261

Check hydraulic reservoir oil level before and after run-up.

8.5 Checking Oil Level in Hydraulic Reservoir, page

262

Check knife drive belt(s) tension.

8.6 Checking Knife Drive Belt Tension, page 263

Check reel centered between header endsheets. 8.8 Centering the Reel, page 268

Grease all bearings and drivelines.

8.17 Lubricating Header, page 292

Check side draper tension.

8.13 Adjusting Draper Tension, page 284

Check draper seal.

8.15 Checking and Adjusting Draper Seal, page 287

Check header float.

—

Check reel tine to cutterbar clearance.

8.11.1 Measuring Reel Clearance, page 278

Check auger flighting to feed pan clearance.

8.12 Adjusting Auger to Pan Clearance, page 281

Check the knife hold-down adjustment.

8.7 Checking Knife Hold-Downs, page 266

Check skid shoes are evenly adjusted at a setting appropriate

for first crop.

—

Ensure feeder house variable speed is set to minimum.

—

Ensure auto header height is calibrated and

functioning correctly.

9 Setting up Auto Header Height Control, page 305

Run-up procedure

11 Running up Header, page 491

Loading...

Loading...