Grove Published 7-23-2020, Control # 668-02 6-33

GRT9165 OPERATOR MANUAL MAINTENANCE AND LUBRICATION

38

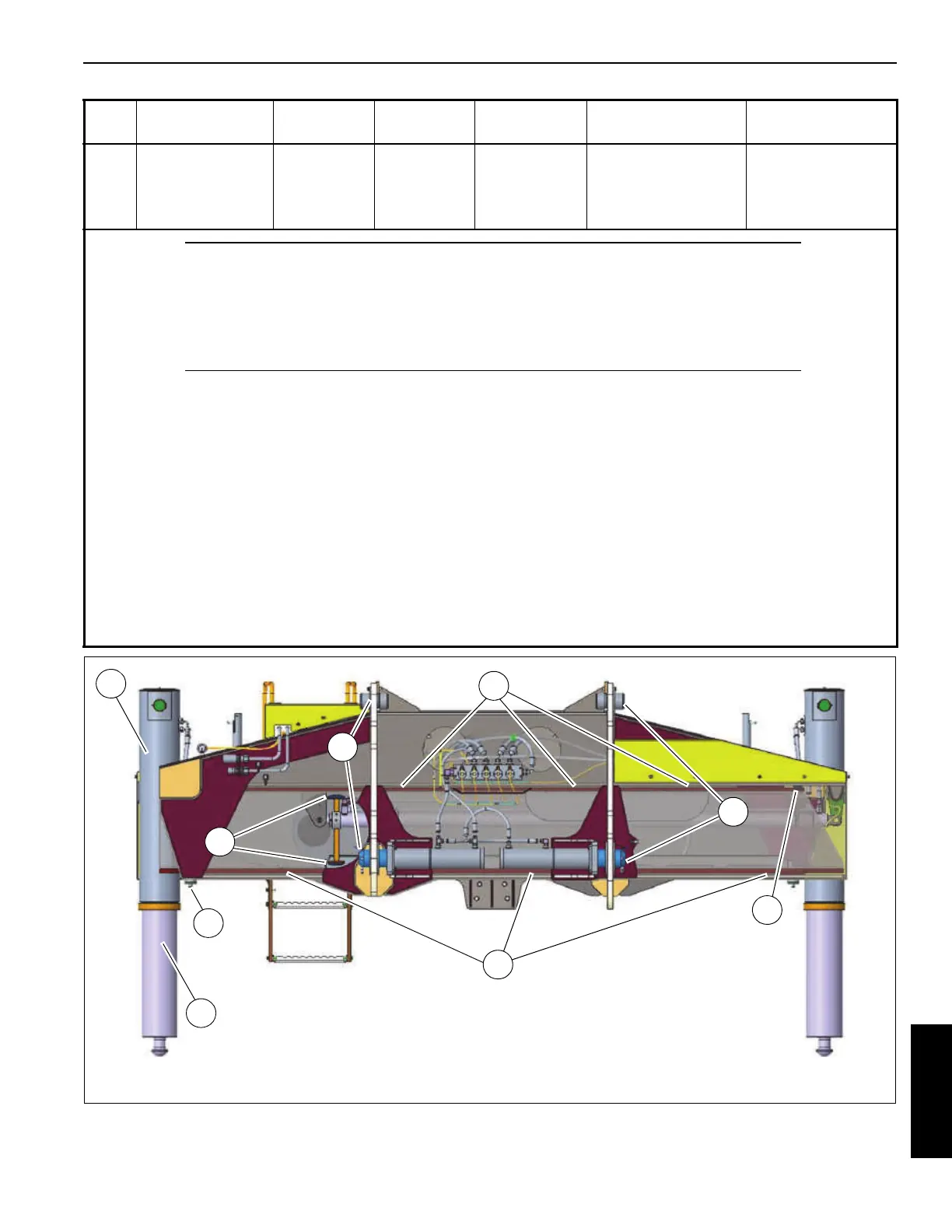

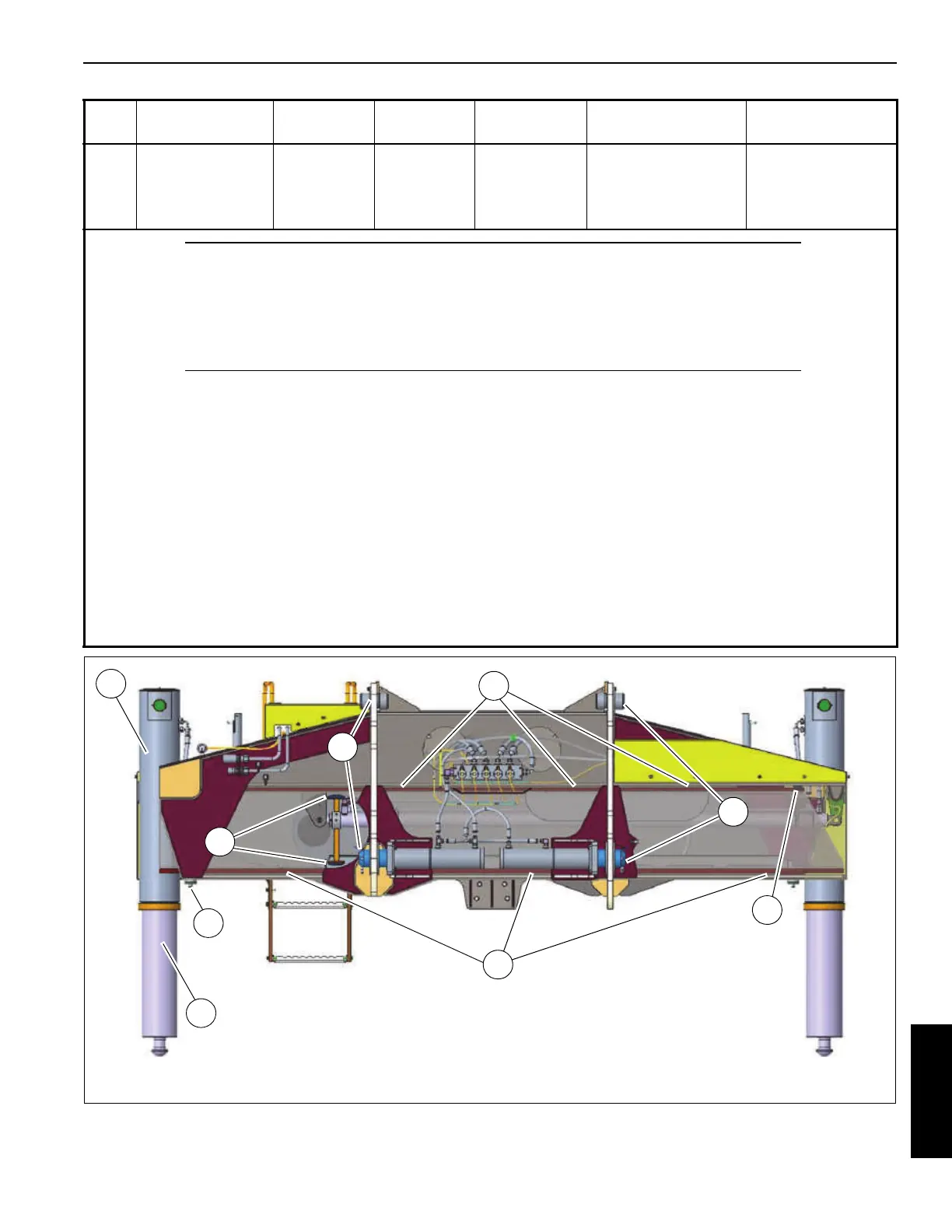

Extend Cylinder

Supports

See NOTE 40.

See NOTE 42.

Figure 6-16 L BRUSH ON

Every 50 hours, or

1 week of service,

whichever interval

comes first

BRUSH ON

8 service points

See NOTE 37.

See NOTE 39.

NOTE 37: DO NOT USE non semi-synthetic lubricant. Use of non-approved lubricant may damage components.

NOTE 38: Brush lubricant in I.D. of Jack Cylinder Support Tubes and Wear Bands before installing Jack Cylinders.

NOTE 39: Brush lubricant on TOP wear pads (rectangular–rear), and BOTTOM wear pads (circular–front) of Outrigger

Beams and Extend Cylinder Supports.

NOTE 40: Brush lubricant on three (3) TOP and three (3) BOTTOM bump-outs found on each side of the outrigger beam

where top and bottom plates contact the sides of the outrigger box. Lubricate 6 points each side, per outrigger,

when the beam is fully extended.

NOTE 41: Perform same service for each of four (4) Outrigger Beams, for a total of 48 service points.

NOTE 42: Before operating crane in cold weather (arctic) ambient temperatures below -9°C (+15°F), Standard grease

must be fully purged and replaced with Cold Weather grease meeting Grove U.S. L.L.C. specifications as

shown in Table 6-4: Approved Lubricant Reference Table, page 6-11 in this Operator Manual. See also your

GRT9165 Service Manual for maintenance and lubrication instructions.

Item

Lube Point

Description

Figure No.

Approved

Lubricant

Approximate

Capacity

Service Interval

Service

Application

CAUTION

Possible Equipment Damage!

Use semi-synthetic or synthetic lubricants as listed in Section 6 of this Operator Manual. See

also your Service Manual for maintenance and lubrication instructions. Use of non-approved,

non semi-synthetic lubricant may damage components and/or invalidate published lubricant

intervals. Failure to follow this instruction may cause damage to equipment.

FIGURE 6-16

OUTRIGGER BOX

9900-14a

37

33

36

36

38

35

35

34

34

35

Loading...

Loading...