National Crane Published 08/16/19 Control # 112-05 7-7

500E2 SERVICE MANUAL LUBRICATION

2. Check alignment between the 2

nd

section access hole

and the 3

rd

section access holes. When these holes

become aligned, the end of the extend cable sheave pin

is visible and accessible for lubrication.

3. This boom position also aligns the access holes at the

rear of the 1

st

section for lubrication of the retract

sheaves.

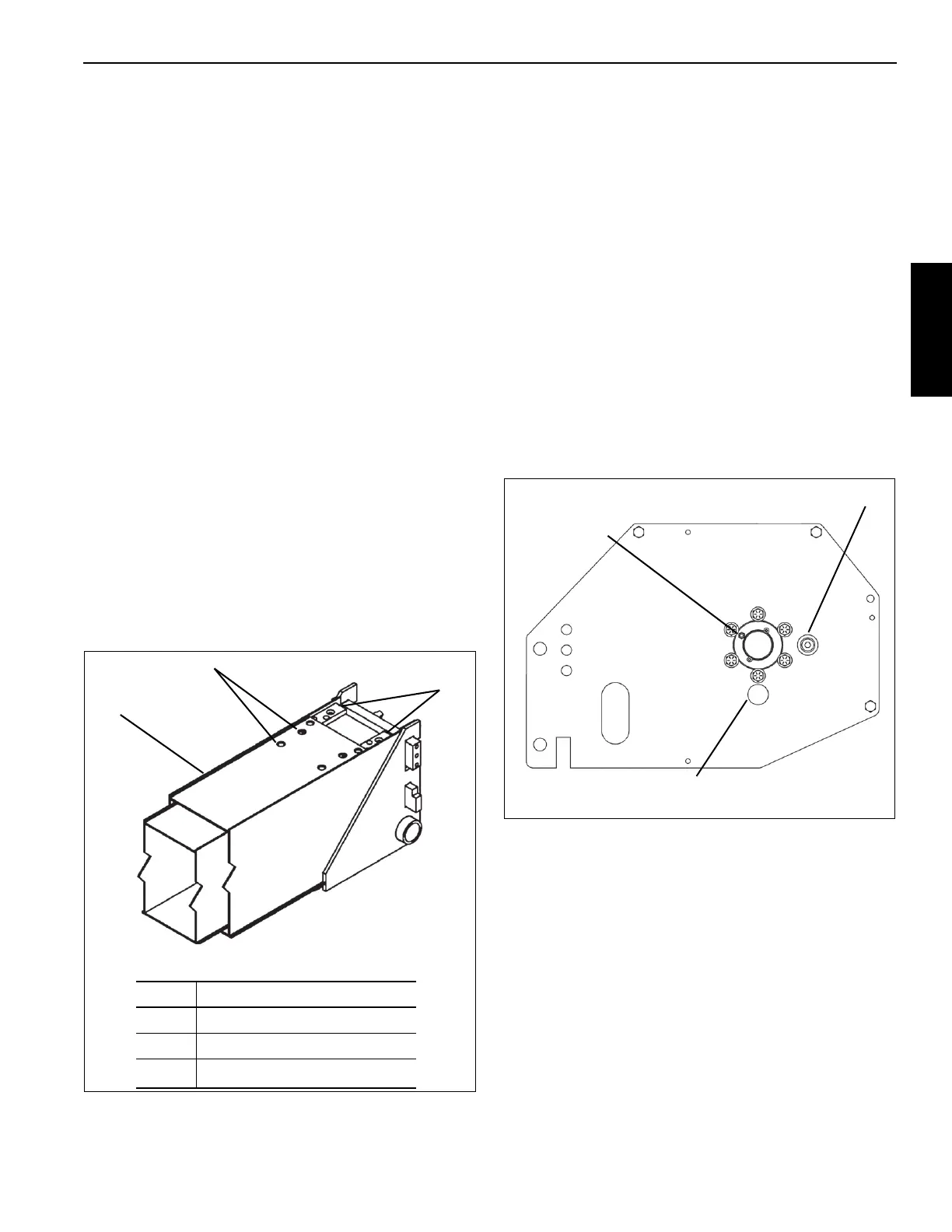

Inner Boom Pad Lubrication

1. With the boom fully retracted, apply grease to the wear

pads on the top of second boom section with a small

paint brush or a grease gun.

2. Extend boom to position the wear pad access holes

directly above the wear pads on the third boom section,

apply grease to the pads using the brush or gun.

3. Extend boom to position the wear pad access holes

directly above the wear pads on the fourth boom section,

apply grease to the pads using the brush or gun.

4. After grease is applied to all wear pads raise the boom to

the maximum angle and slowly extend the boom to full

extension and slowly retract completely.

5. Repeat steps 1 - 4 three times to ensure the boom is

fully lubricated.

Side and Bottom Boom Wear Pad

Lubrication

1. Fully extend and set the outriggers.

2. Lower the boom to horizontal.

3. Fully extend the boom and apply grease to the side and

bottom of the 2

nd

and 3

rd

sections with a brush.

4. Raise the boom to about 75° and retract the boom

5. Extend and retract the boom several times until the

grease is evenly spread.

6. Repeat steps 1-3 as necessary to ensure the boom is

fully lubricated.

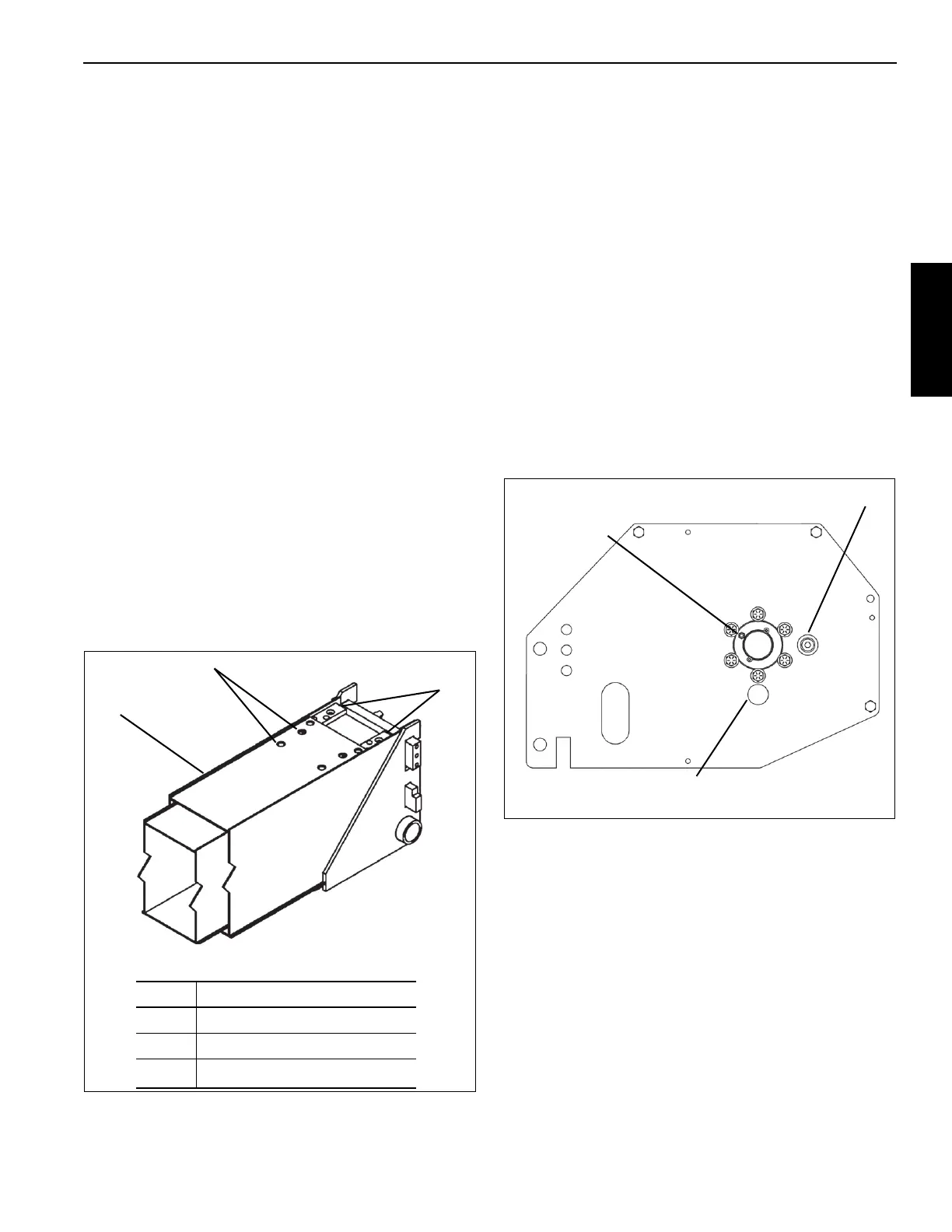

Hoist Gearbox Oil

Use the following procedures to change the hoist gearbox oil

(Figure 7-1).

NOTE: Hoist gear and brake lubricants are satisfactory for

operation in temperatures from -10°F to +110°F (-

23°C to 43°C). For operation outside this range,

contact Manitowoc Crane Care for

recommendations.

Hoist Gearbox Oil Change

To change the hoist gearbox oil, rotate the drum so that the

plug is visible through the lower hole in the side plate (See

33, Figure 7-2, view 1). Screw in a piece of 1 inch pipe in the

gearbox oil drain to allow the oil to drain. Remove the

gearbox vent (30, Figure 7-2, view 1), then with a hex

wrench remove the drain plug located inside of the 1 inch

pipe (See Figure 7-2, view 2). Examine the used oil for signs

of significant metal deposits and then dispose of it in a proper

manner. Remove the 1 inch pipe.

Rotate the drum so that the port is visible through the

gearbox oil fill and level hole in the side plate (Figure 7-1).

Install a 1 inch pipe with elbow into the upper hole in the side

plate (See Figure 7-2, view 3). Fill the gearbox with

Item Component

1 First Section of Boom

2 Wear Pad Access Holes

3

Third

Section Wear Pads

1

2

3

Gearbox Oil Drain

Gearbox Vent

Gearbox Oil Fill

and Level

FIGURE 7-1

9871

Loading...

Loading...