National Crane Published 08/16/19 Control # 112-05 9-37

500E2 SERVICE MANUAL CRANE INSTALLATION

INITIAL CRANE RUN IN PROCEDURE

1. Engage the PTO and run the truck engine at idle to

activate the pump (approximately 600 rpm). Turn the

crane power switch on and operate the crane and

outriggers though all of their functions at least six (6)

times to purge cylinders of air. Operate the control

valves slowly with the truck engine at idle and cycle each

cylinder through its complete stroke each time. Check to

see that movement of outriggers and boom correspond

with direction indicated on switches and levers. Refer to

hydraulic or electrical schematic and parts pages to

correct any problems.

NOTE: Add oil to reservoir as required to keep air from

reentering the system.

2. Set throttle according to engine RPM and PTO ratio to

get 2400 RPM pump shaft speed.

3. When all cylinders have operated through complete

cycles, stow crane and place the outriggers in the up

position. The oil level should be visible near the top of

the sight gage. Lift and stability test must now be

performed on the unit. Hoist and crane tests should be

conducted to insure proper performance.

4. After testing is completed, all cable clamp bolts should

be re-torqued to specifications. Inspect the T-box and

frame mounting bolts for proper tension.

5. Upon completion, overall height of crane vehicle

combination must be measured and posted inside of cab

informing driver of overall height.

STABILITY CHECK

The chassis weight, before the crane is mounted, is intended

for use only as a guideline in determining the total weight

required for the unit to be stable with an 85% tipping factor

(i.e. when lifting capacity load, the unit is at 85% of tipping or

less).

In order to ensure the stability of the unit with an 85% tipping

factor, a live load stability test must be performed on each

completed unit. Proceed as follows:

1. Test the unit for stability on a firm level surface.

2. A Series 500E2 Service Manual crane requires rear

stabilizers for stability. With the boom stowed, set the

unit up level on the outriggers and stabilizers.

3. When stability testing this unit, select the load from the

capacity chart that is listed at the longest boom

extension and approximately 30° of boom elevation.

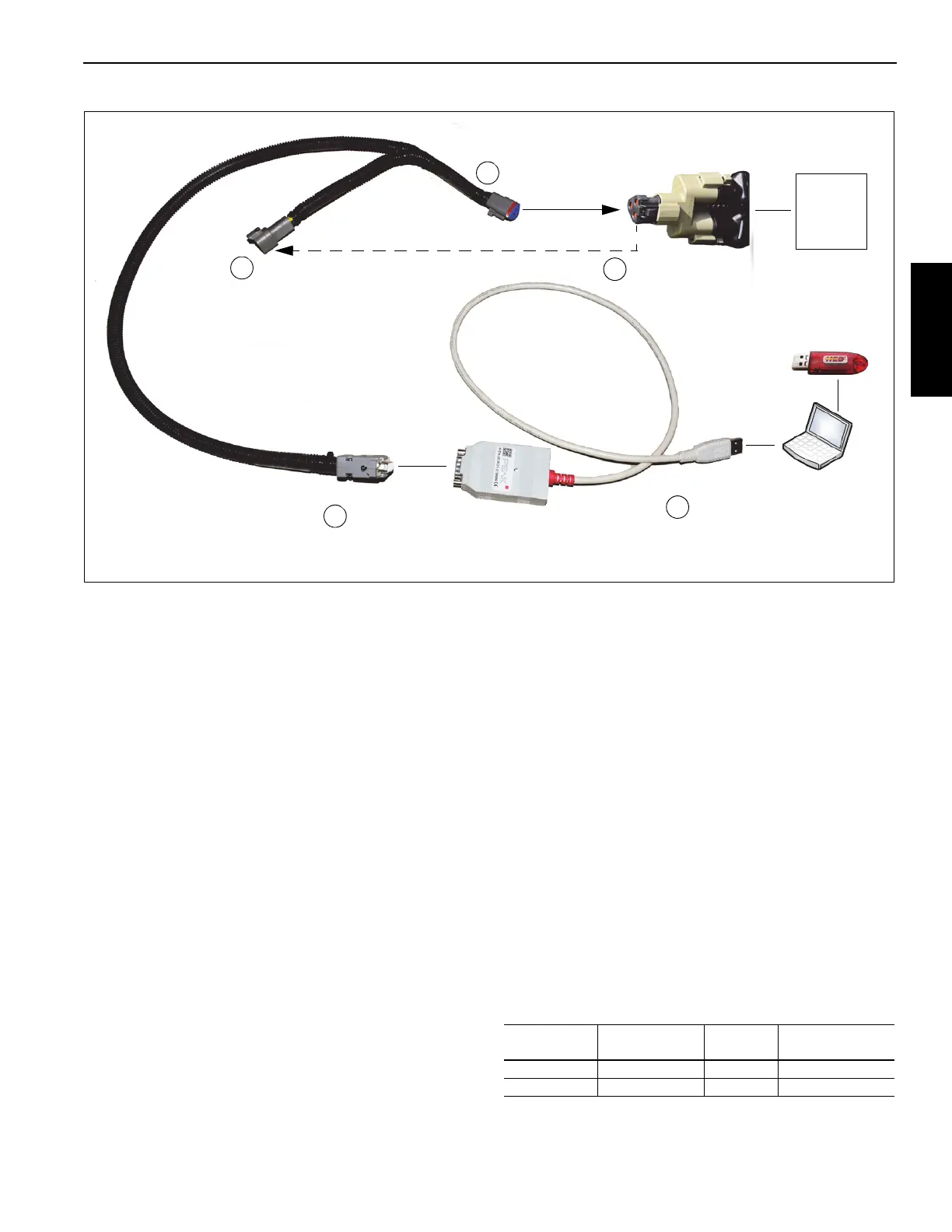

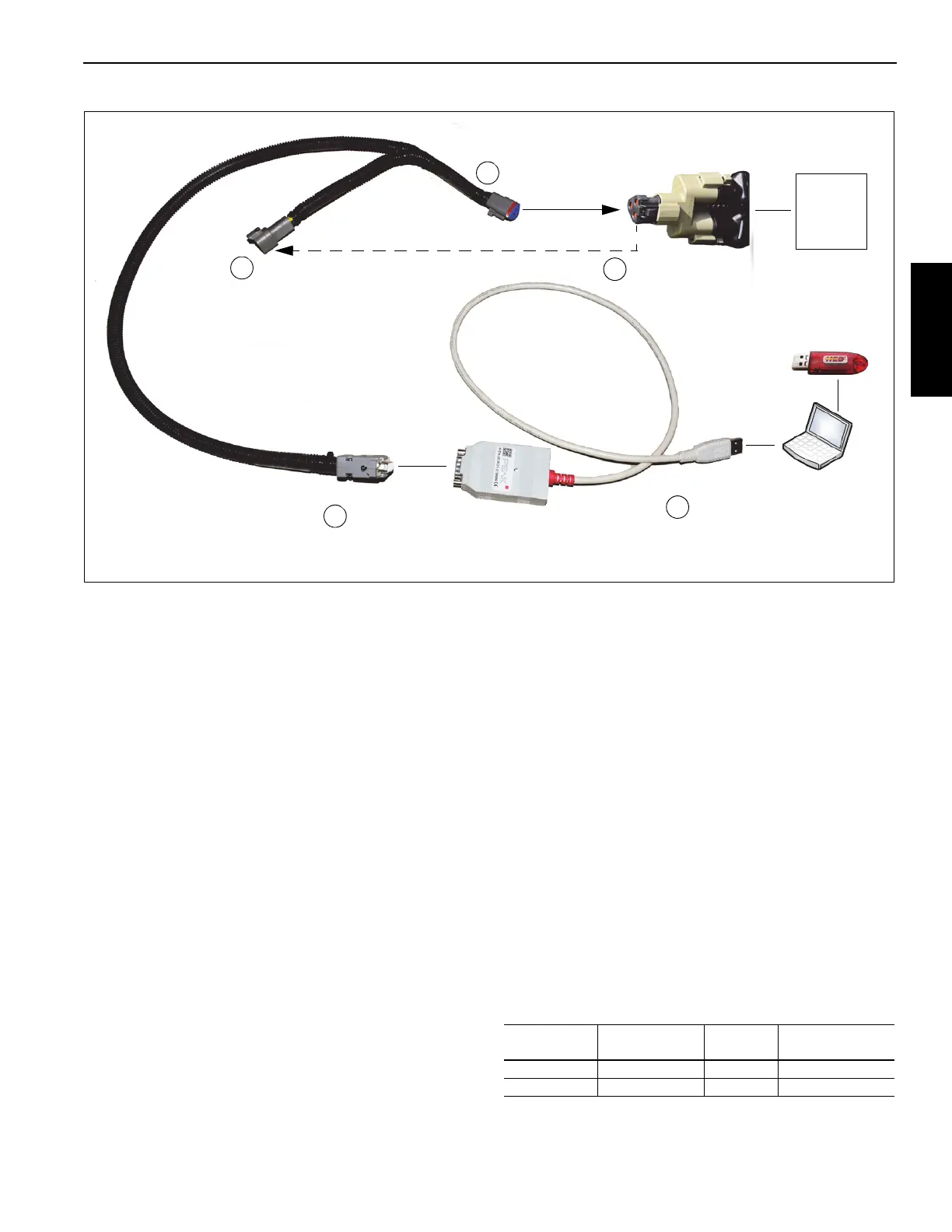

Diagnostics Cable

CAN to USB

Adapter Cable

OMS

Module

Laptop

FIGURE 9-4

Install terminating

resistor.

Remove terminating

resistor from splitter.

1

2

Connect cable.

3

Install serial end of

diagnostics cable to CAN

to USB adapter cable.

4

Connect USB

to laptop.

5

9832

9833

9836

Software

Key

9835

Model

Boom

Length

Loaded

Angle

Loaded

Radius

560E2 60' (18.28 m) 34.5° 50' (15.24 m)

571E2 71' (21.64 m) 32° 60' (18.29 m)

Loading...

Loading...