National Crane Published 08/16/19 Control # 112-05 9-31

500E2 SERVICE MANUAL CRANE INSTALLATION

Counterweighting Methods

Two methods of counterweighting may be used:

a. a heavy front bumper and concrete in the bed or

b. concrete in the bed only.

The easiest and most economical method is usually

concrete in bed only. The amount of counterweight required

will be 1132 + 918 = 2050 pounds (513 + 417 = 930 kg). Use

2350 pounds (1066 kg) of concrete poured in the front of the

bed. See “Counterweighting for 180° Stability” in this section

Determine axle weights added by the counterweight by using

the same method as used before. Figure the center of the

counterweight to determine where the weight acts. If the

counterweight is oddly shaped, figure the center and weight

of each regular shape. Weights ahead of the front axle

require using a negative (-) distance in calculations.

The rear axle weight is 284 lbs (130 kg) heavier than required and the front axle weight is 16 lbs (6 kg) heavier than required.

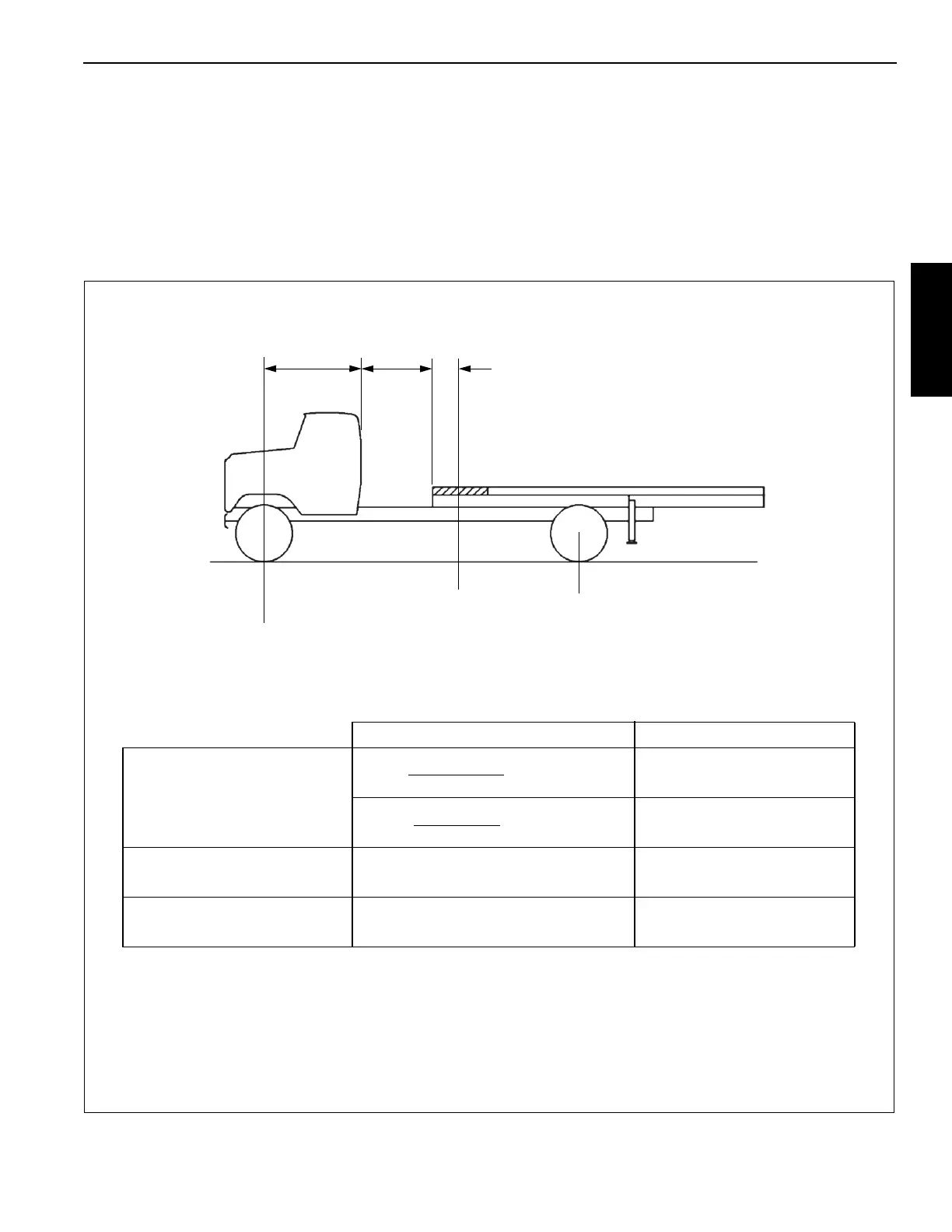

Rear Axle Weight Front Axle Weight

1150 lb (520 kg) Bed Concrete

Required Counterweight

Difference

(2350) - 1416 = 934 lb

1132 lb

(2350) x 142.8

=

1416 lb

237

(1066) x 363

=

634 kg

602

513 kg

284 lb

130 kg

(1066) - 643 = 423 lb

918 lb

417 kg

16 lb

6 kg

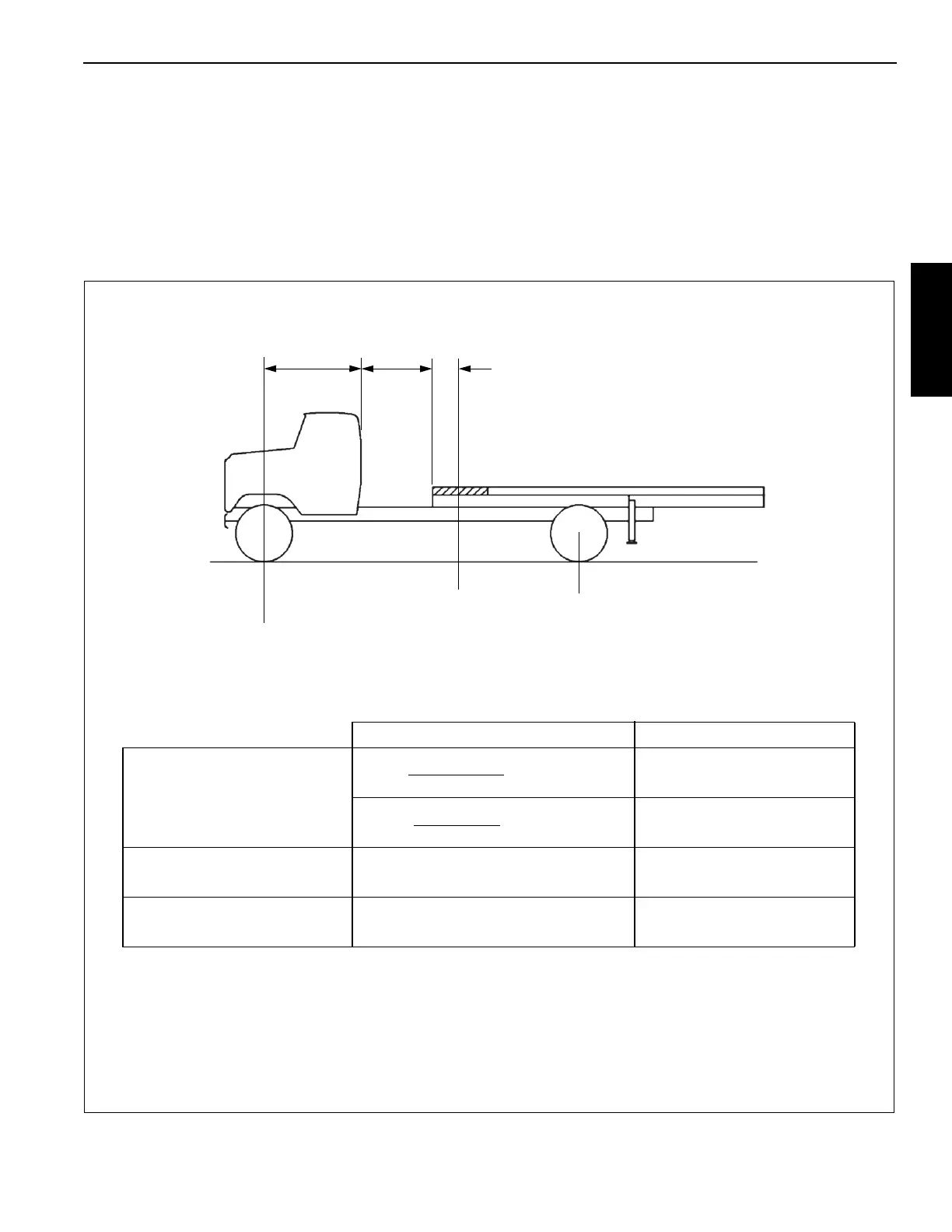

142 in (363 cm)

2350 lb (1060 kg)

Concrete

237 in (602 cm)

0 in

69 in

(175 cm)

53.8 in

(137 cm)

20 in

(51 cm)

Loading...

Loading...