INTRODUCTION 500E2 SERVICE MANUAL

1-6 Published 08/16/19 Control # 112-05

.

Dielectric Grease

Dielectric grease was applied to the following connections at

the factory when the crane was assembled. When servicing

electrical connections, dielectric grease must be re-applied

to these connections.

• All Deutsch Connectors

• All Valve Solenoid connections on Hydraulic valves and

Transmissions

• All Harness Connections

• RCL Module Connections (except M12 and M8

connectors)

Excluded Connections

Do not apply dielectric grease to the following connections:

• All Connections Inside the Cab

• M12 and M8 Connectors

• Pin-type Contacts

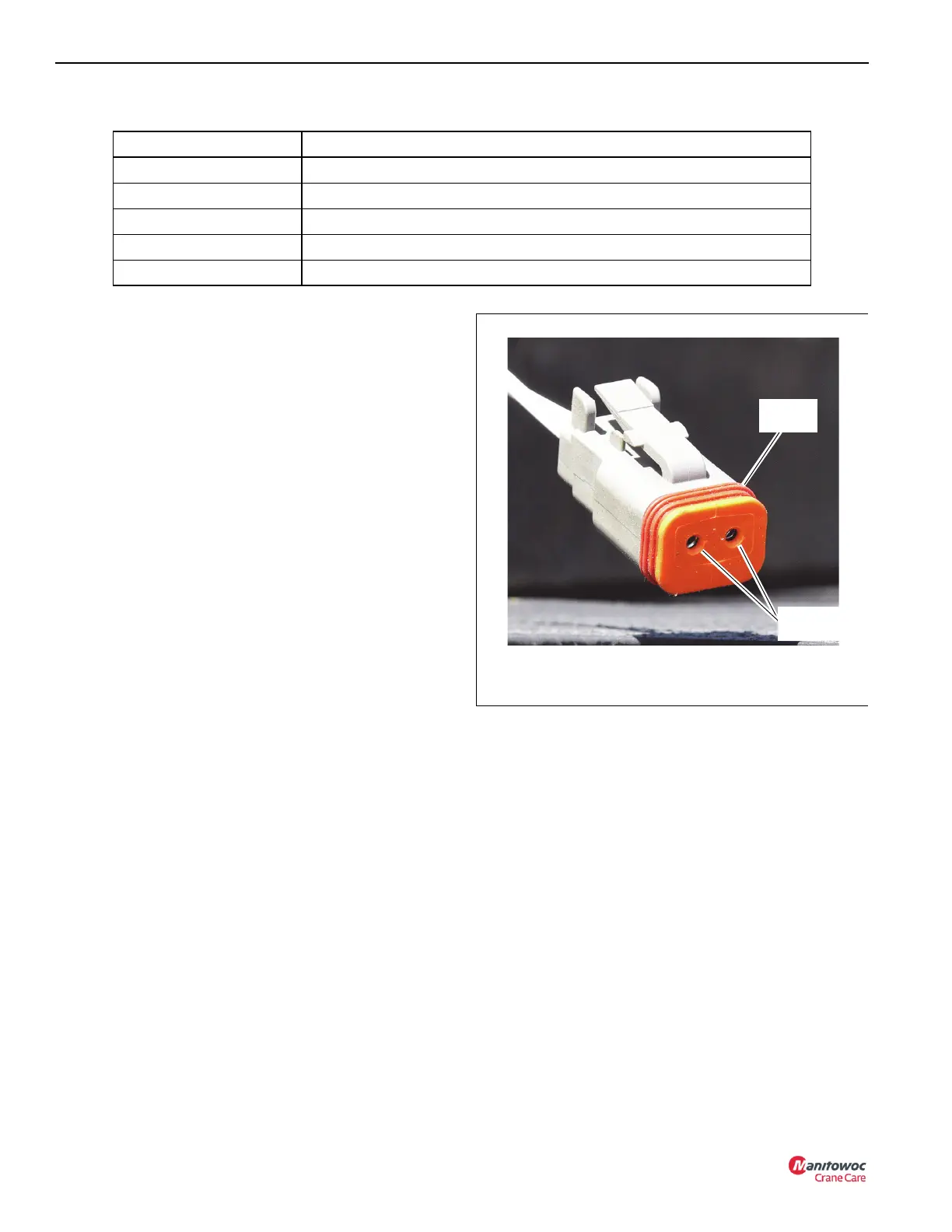

Applying Dielectric Grease to an Electrical Connector

Use the following procedure to apply dielectric grease to an

electrical connection. Grease should be applied immediately

prior to securing the connector. Ensure that grease is applied

to all terminal sockets (Figure 1-1).

1. Check the connection for moisture before application of

the grease. If moisture is found, clean or replace the

connector as necessary.

2. Screw a tip or trigger assembly on to the can of dielectric

grease if necessary.

3. Apply the grease onto socket (female) contacts.

4. Use a clean towel to remove excess grease from the

surface of the connector, and wipe grease into the

terminal sockets (Figure 1-1).

5. Ensure grease is applied to each terminal socket. The

towel with excess grease can be used to fill empty

terminal sockets (Figure 1-1).

6. Ensure grease is applied to the entire surface of the

connector’s rubber seal (Figure 1-1).

NOTE: Do not allow grease to come in contact with any

painted surface, or any other components.

7. If clean up is necessary, contact cleaner or petroleum

distillates can be used.

8. Secure the connector when complete.

FATIGUE OF WELDED STRUCTURES

Highly stressed welded structures are subject to cracking

(fatigue) when repeatedly subjected to varying stresses

caused by twisting, shock, bending, and overloads. Inspect

equipment periodically for weld fatigue. The frequency of

Climate Zone Classification

Zone Classification

A (Tropical Moist) Latitude 15° - 25° North and South (All months average above 64° F [18° C])

B (Dry or Arid) Latitude 20° - 35° North and South (Deficient of precipitation most of the year)

C (Moist Mid-Latitude) Latitude 30° - 50° North and South (Temperate with mild winters)

D (Moist Mid-Latitude) Latitude 50° - 70° North and South (Cold winters)

E (Polar) Latitude 60° - 75° North and South (Extremely cold winters and summers)

Rubber

Seal

Terminal

Sockets

Example. For illustration purposes

only. Your connector may differ.

FIGURE 1-1

9746

Loading...

Loading...