9-28 Published 08/16/19 Control # 112-05

CRANE INSTALLATION 500E2 SERVICE MANUAL

Wire Rope Installation

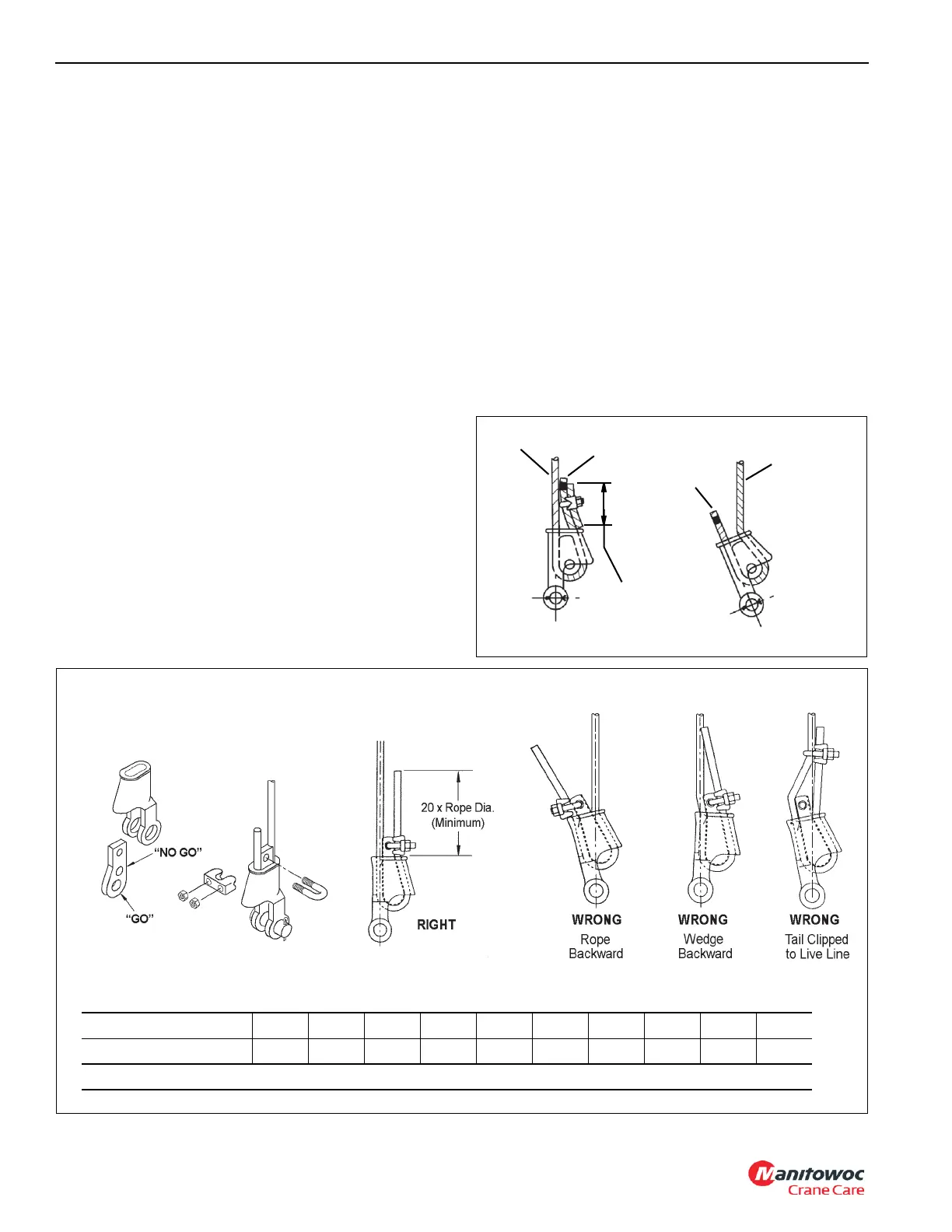

1. Unspool approximately 15 feet (8 m) of cable and route

the cable through the boom cable guides from the front

of the boom to the hoist.

2. Install one end of the loadline cable into the hoist drum

using the wedge socket provided.

3. Remove the cable keeper T-handle pin from the sheave

case and lay the cable over the top sheave. Replace the

top cable keeper pin.

4. Unspool the remainder of the cable out from the back of

the truck being sure the cable is straight and without

kinks. Attach downhaul weight, wedge socket, hook and

cable clamp to the end of cable as shown in Loadline

Section. Torque cable clamp (clip) to 95 ft-lb (128 N·m).

This torque must be rechecked after initial operation of

the crane. Be sure cable clamp is attached to the free

end of the cable only. If equipped with optional 2/3 part

block, omit downhaul weight and assemble as shown in

Loadline Section. Special care should be taken to reeve

the cable through the wedge socket as shown below.

5. Spool the loadline onto the hoist drum while maintaining

approximately 500 pounds (250 kg) of tension on the

cable (attaching a small vehicle to the end of the loadline

with another person lightly riding the vehicle brakes

while the cable is spooling on the drum will accomplish

this). While the first half of the hoist bare drum is filling, it

will be necessary to force the cable to wrap tightly

against the preceding wrap by pounding the cable

against the preceding wrap with a rubber mallet until at

least half of the drum is full. The remaining half of the

drum should wrap tightly because the fleet angle of the

cable will tend to pull the cable to the center of the drum

thus wrapping tightly.

6. Continue winding the cable on the second, third and

fourth layer of the drum. Keep the cable paying in

straight to the boom to avoid side loading the boom. The

preceding layers will wrap smoothly guided by the first

layer wrapping.

7. After cable is completely wrapped on drum, replace

remaining cable keeper bolts on the sheave case. Attach

wedge socket and cable clip to end of cable per

illustration in Loadline Section of parts manual and

torque cable clip bolts to 95 ft-lb (128 N·m) for 9/16 inch

cable.

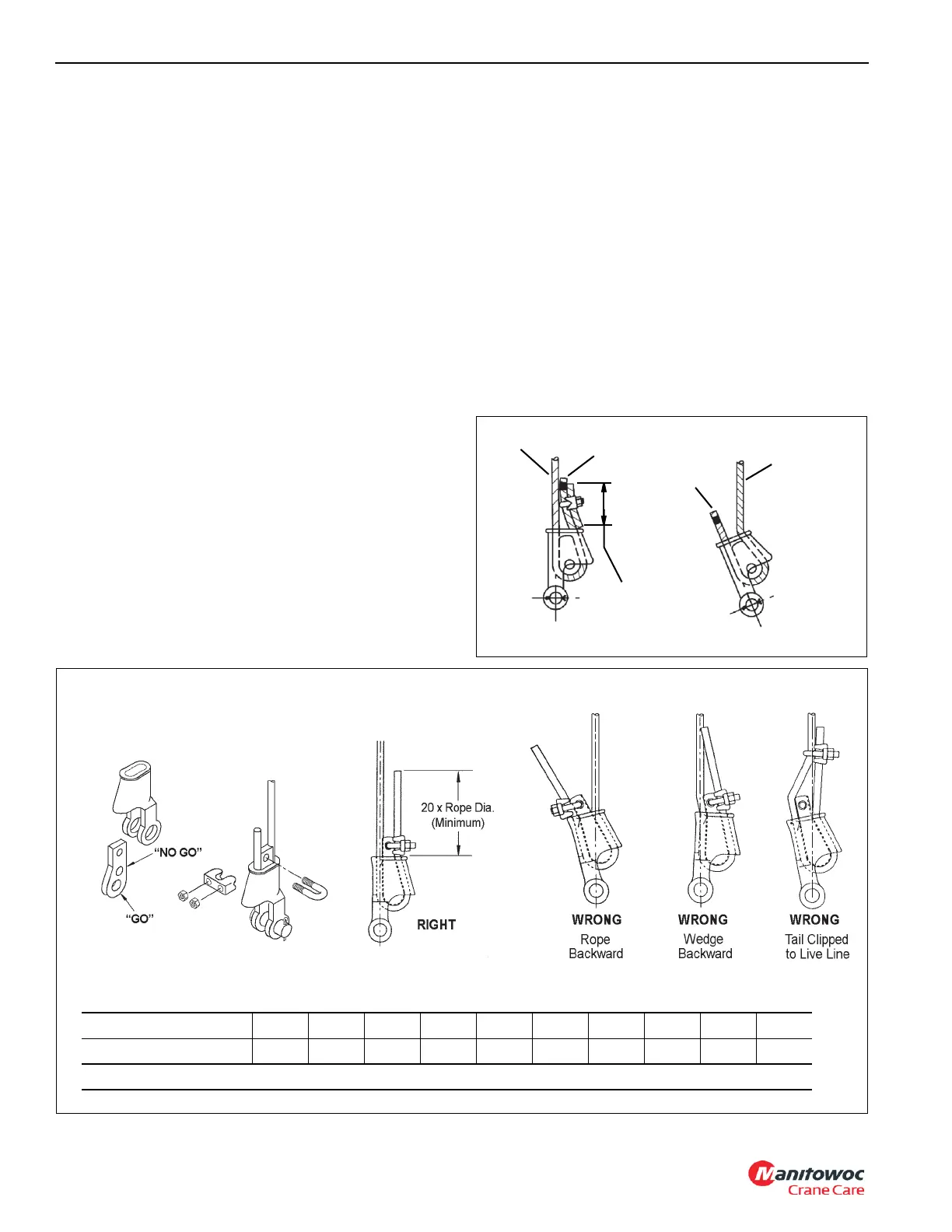

Dead

End

Dead

End

Live End is

Entering

Wrong Side

Live

End

20 x Cable Dia

Minimum

RIGHT

WRONG

Wedge Socket

Torque Value Table

Cable Size (inches) 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4

Torque ft/lbs 45 65 65 95 95 130 225 225 225 360

Torque values shown are based upon clean dry threads free of lubrication.

Terminator Wedge Socket

Loading...

Loading...