National Crane Published 08/16/19 Control # 112-05 3-13

500E2 SERVICE MANUAL ELECTRIC SYSTEM

1. Remove faceplate from transmitter. Make sure

that leads to each lead screw on toggles are

secure and will not be at an angle where it

would be touching anything when replacing the

faceplate.

2. Disconnect wiring harness from PC board and

then reconnect the same way. Be sure that no

wires are loose at connector and that connector

is secure on connector pins. The wiring harness

should be positioned between toggle housings

or where it is not hanging down creating a bind

when replacing the faceplate.

3. Refer to 3B.

Example to follow on existing equipment

4. Activate a function (boom up) on the transmitter, at this

time the receiver’s RF Indicator LED and the appropriate

Output Status Indicator LED will be on. And if the

function activated, such as the boom up motion does not

occur, check the following:

a. Be sure that the appropriate orange connector pin

matches the Output Status Indicator LED. There

should be 12 or 24 volts DC to that output,

depending on the power supplied from the vehicle. If

it is determined there is power to the output, then

the wiring and hydraulic system should be checked.

b. If the appropriate Output Status Indicator LED is

turned on and there is no power to the orange

connector pin, this indicates that a circuit failure has

occurred and the radio controller must be repaired

at the factory.

5. If crane function occurs when function switch is

activated and before trigger is pulled, readjust the low

end proportional potentiometer in the receiver. See

Installation Section for correct procedure.

Specifications

Installation

Transmitter

Each unit’s address code has been preset by the factory.

(We advise not to change codes without first consulting

factory.)

Receiver Mounting

The receiver should be mounted on the crane console. If

installed in a tool box or compartment, care should be taken

in routing cable and wires so when tools and supplies are

inserted or removed they do not snag or pull on the cabling.

If mounting on a vertical plane, ideal mounting would be to

place the connectors pointing down. Adequate planning is

required so wire routing can be accomplished. You must

keep in mind that the unit comes standard with 20 feet of

antenna cable. Use the mounting holes on the receiver for

securing the system. Once mounted, remove the cover to

inspect the Status Indicators. (Refer to the Receiver Printed

Circuit Board drawing, Figure 3-6, in the following steps.)

Connector Instructions

Strip all wires to be inserted into the 20 pin connector, to a

length of 3/8 to 1/2 inch (10 mm to 13 mm). Solder the loose

wire strands into one solid wire. Insert a small straight blade

screwdriver into the square hole of the desired pin. Prying

towards the face (lid) of the receiver, insert the appropriate

stripped wire into the round hole directly below the

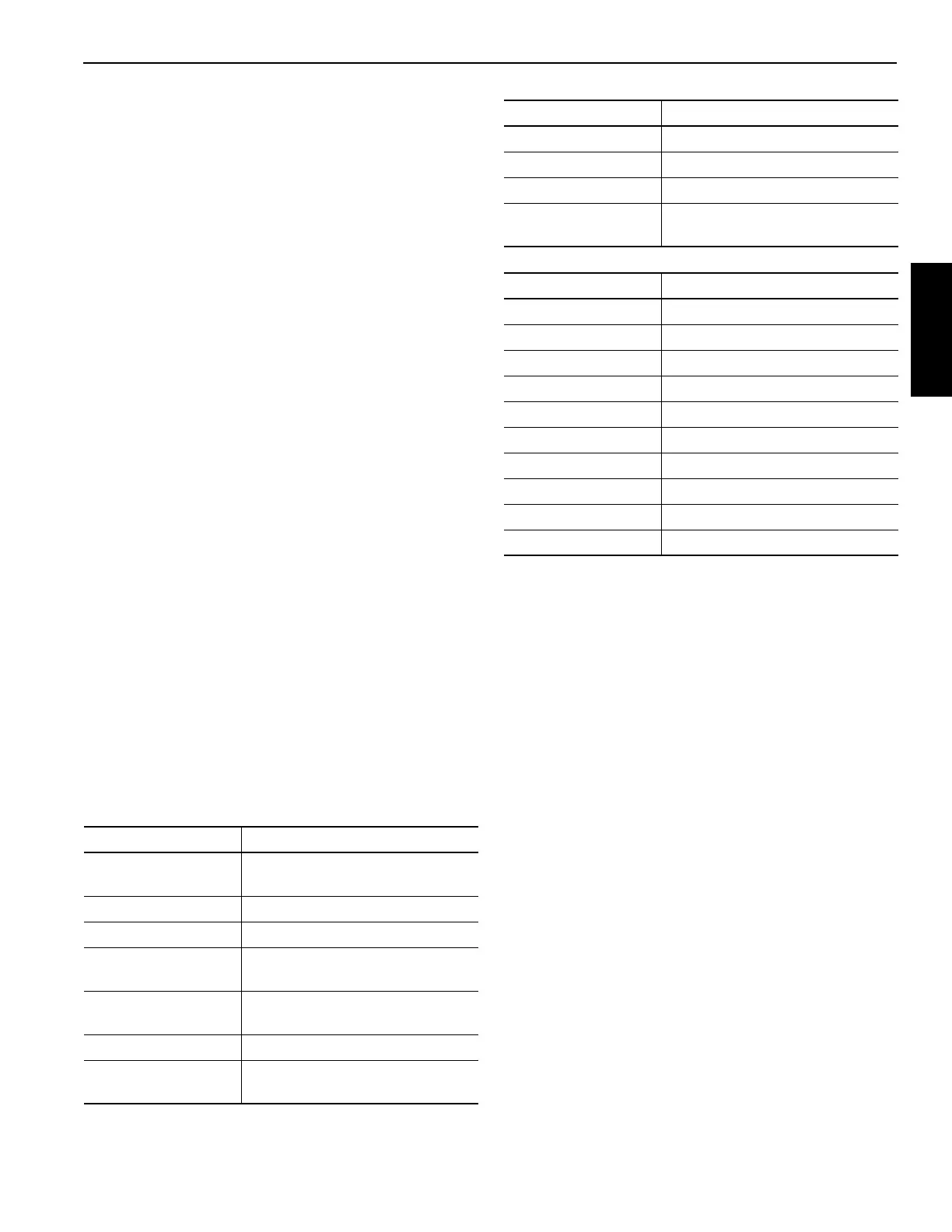

Transmitter Description

Material

Composite plastic (high impact

plastic material)

Seal Water resistant enclosure

Color Light gray

Switch Type

Industrial environmentally sealed

toggle

Dimension

9” L x 5-3/4” W x 4-3/4” D (including

handle)

Approximate Weight 2.5 lb

Power Source

9 volt battery (disposable, not

rechargeable)

Antenna External 6: (Rubber Ducky)

Operating Temperature

-20°C to +50°C (-4°F to +122°F)

Frequency 49 MHz Band

Address Codes

>20,000 combinations including RF

bands

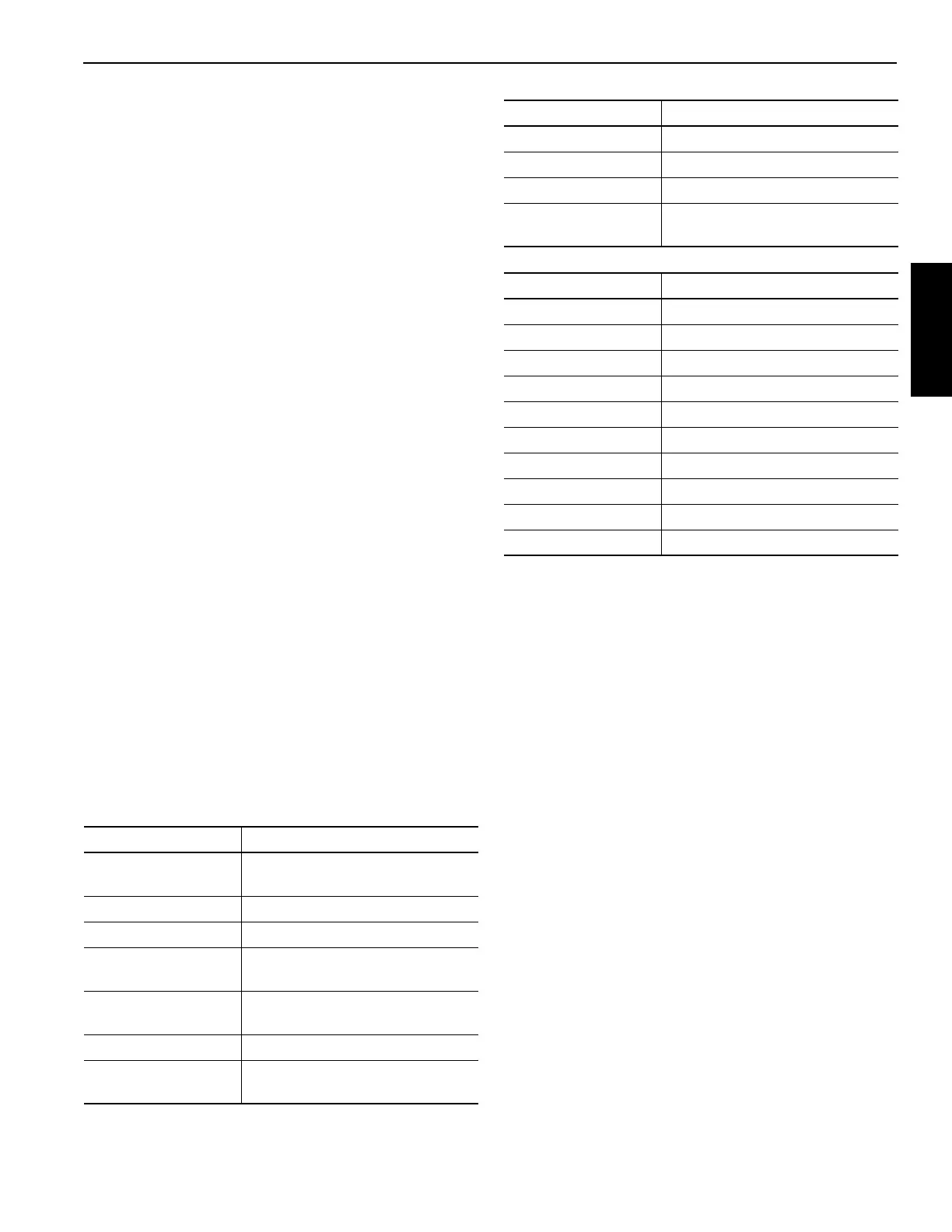

Receiver Description

Material 18 gauge aluminum housing

Color Light gray

Dimension 9” L x 7” W x 2” D

Approximate Weight 3 lb

Number Outputs 1 to 17

Control Voltage Range 10 - 24 VDC

Power Supply Operation

10 - 24 VDC

Connector Cage-Clamp style connection

Temperature Range

-20°C to +50°C (-4°F to +122°F)

Fused Outputs 7.5 Amp fast blow fuse

Transmitter Description

Loading...

Loading...