3-4 Published 08/16/19 Control # 112-05

ELECTRIC SYSTEM 500E2 SERVICE MANUAL

20. Visually inspect interior routing of anti-two-block wire for

excess slack in wire, inaccurate routing of wire, etc.

Correct any problems before boom operation.

HYDRAULIC CAPACITY ALERT SYSTEM

This hydraulic capacity alert system uses the work port

unloader solenoids in the anti-two-block system as the

hydraulic system dump circuit.

The hydraulic capacity alert system has an override switch

and button located on the operator’s console that

momentarily overrides the hydraulic capacity alert and anti-

two-block systems and restores power to crane functions.

When trip pressure is reached, the pressure sensing switch

breaks electrical continuity to the work port unloader

solenoid in the main control valve.When power is removed

from this solenoid, the unloader valves allow the oil flowing to

hoist up, telescope out and boom down to flow to tank. This

path to tank will prevent further operation of these functions.

When the overload condition is corrected by hoisting down,

retracting the boom, or raising the boom, the pressure

sensing switch allows the work port unloader solenoids to be

powered thereby allowing the crane to function normally.

HCA Maintenance & Repair

The following step-by-step analysis will be helpful in isolating

and correcting almost every service problem if followed in a

step-by-step systematic manner. Use this information with

the Hydraulic Schematic and the Illustrated Parts Catalog to

identify parts and follow flow paths. Start at top box and work

downward step by step. Do not try to start in the middle or

skip steps.

1. Refer to Hydraulic Schematic and System Description to

gain a thorough understanding of the capacity alert

system before proceeding with any maintenance.

2. System adjustment must be checked every three

months for accuracy. Refer to the preceding section on

System Adjustment.

3. Always be sure the boom is adequately supported and

no hydraulic pressure remains in the lines before the

pilot pressure line fittings are loosened.

HCA System Adjustment

The hydraulic capacity alert system should be checked for

proper adjustment during initial crane start-up and quarterly

thereafter. The procedure for proper adjustment should be

performed as follows:

NOTE: Trapped air must be bled from the system before

adjustments are made.

1. Remove the console cover on the operators console.

.

2. Start the truck and set the crane up for operation as

prescribed in the Operators Manual.

3. Select a test weight that is equal to crane capacity at an

intermediate boom length and radius.

4. Work with loads which have loaded boom angles near

30°. Starting with the boom at the chosen reference

angle and a radius less than the chosen radius, pick the

weight up with the hoist and begin extending the boom.

5. As the boom is extending, lower the load with the hoist to

keep the load near the ground.

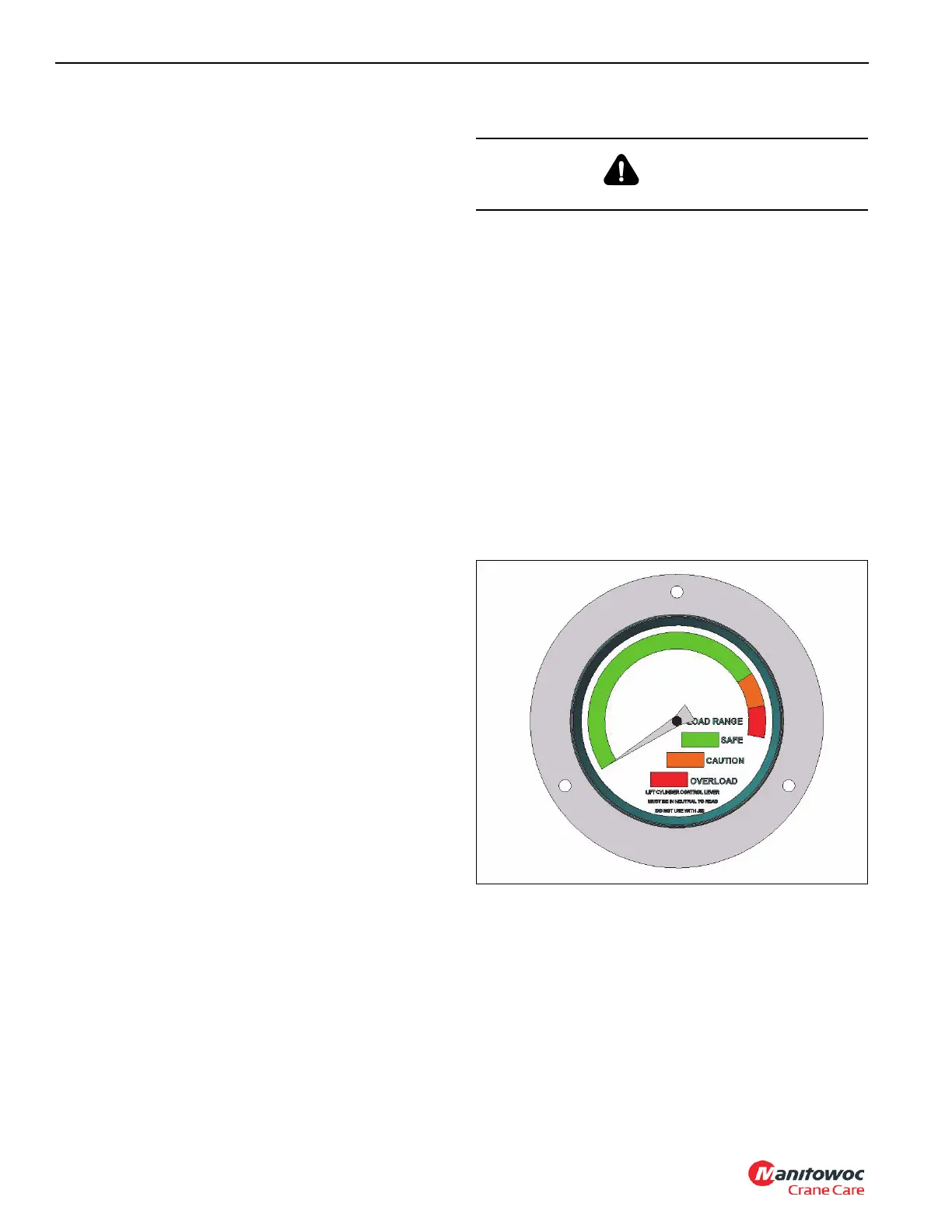

6. Monitor the load range gage located in the console as

the boom is extending. The gage is plumbed directly into

the lift cylinder pilot line and the pressure reading should

increase to what is defined as capacity load pressure as

the selected intermediate boom length and radius is

reached.

7. The intermediate boom length is determined by a line

and corresponding dimension decal on the side of the

second section boom. The chosen radius is measured

from the centerline of rotation to the loadline.

8. If the gage reading does not increase while extending,

lower the load to the ground and check the system

plumbing according to the hydraulic schematic.

Re-plumb the system according to the schematic and

illustrated parts page or replace faulty pressure gage.

WARNING

Before loosening any fittings, support the boom.

Loading...

Loading...