National Crane Published 08/16/19 Control # 112-05 6-11

500E2 SERVICE MANUAL SWING

BEARING REPLACEMENT

Removal

1. Fully extend and set the outriggers enough to take up

the slack in the pads.

NOTE: Do not raise the machine on the outriggers.

2. Rotate the boom to about 10° off the rear position so that

the boom is clear of the boom rest.

NOTE: The lift cylinder pins need to be accessible from the

truck deck.

3. Elevate the boom slightly and shut down the engine.

4. Tag and disconnect the battery cables.

5. Remove the boom and lift cylinder following the

procedures outlined in “Boom Removal” on page 4-3.

NOTE: If equipped with a swivel, tag and disconnect all

hydraulic lines from the swivel on the carrier side.

Cap or plug all lines and openings. The swivel is

removed with the turret.

6. Attach a suitable lifting device to the turret. Remove any

slack in the sling. Do not pull up on the turret.

7. Remove all bolts and washers from the outer race of the

swing bearing.

8. Carefully lift the turret with bearing off the truck and set it

on blocking that will not allow the turret to tilt or shift.

Leave the lifting device attached.

NOTE: If the current bearing is to be reinstalled, mark the

position of the bearing on the turret before removal.

9. Remove all bolts from the inner race of the swing

bearing.

10. Lift the turret off the swing bearing and set on blocking.

NOTE: The bearing weighs about 415 lb (188.2 kg).

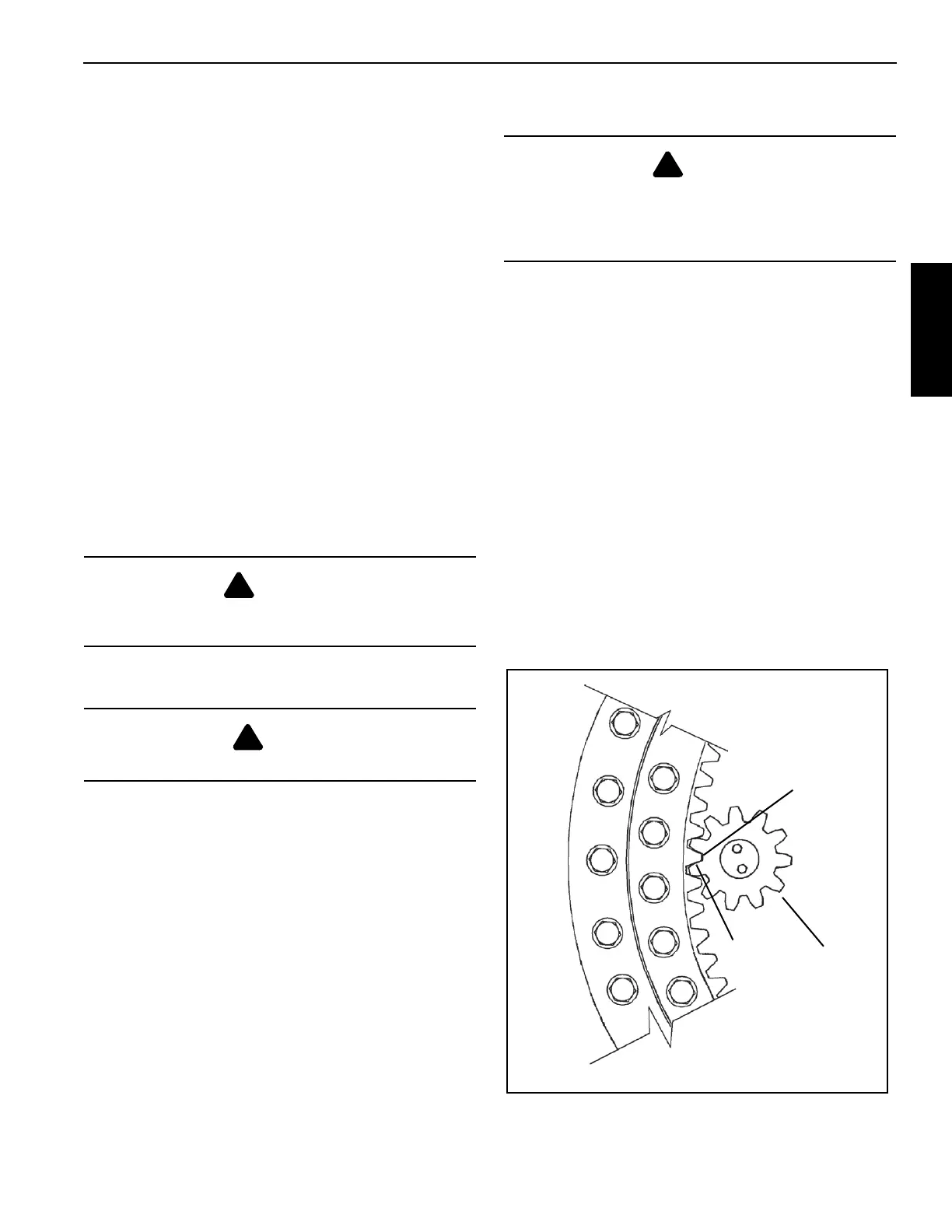

Check the bearing teeth for chipping or cracking. If any

evidence of these is found, replace the bearing. Ensure the

bolt holes are free of dirt, oil, or foreign material.

Installation

NOTE: If the current bearing is reinstalled, align the

marked teeth on the swing drive pinion shaft with

the marked teeth on the bearing.

1. Using an appropriate lifting device, set the turret on the

swing bearing. If the same bearing is being used,

position it as marked prior to removal.

2. Install new bolts and washers securing the bearing to the

turret. Refer to “Inner Race Torquing” on page 6-9.

3. Using an appropriate lifting device, align the turret over

the frame at the same position that it was before

removal.

4. Carefully lower the turret into position on the bearing

plate.

NOTE: If equipped, be careful not to damage the swivel

assembly.

5. Install all bolts and washers to secure the outer race of

the swing bearing to the T-box frame. Refer to “Outer

Race Torquing” on page 6-9.

DANGER

Ensure the lifting device is capable of supporting the

boom assembly.

DANGER

Ensure blocking material can support the turret.

DANGER

Do not reuse the swing bearing bolts. The swing bearing

is torqued to the applied torque of the grade 8 bolts. New

bolts ensure proper torque and bolt strength for securing

the swing bearing and turret to the frame.

0.008 Shim

Maximum

Eccentricity

Tooth

Pinion

FIGURE 6-5

Loading...

Loading...