Published 08/16/19 Control # 112-05 1-25

500E2 SERVICE MANUAL INTRODUCTION

National Crane

Wire Rope Replacement (All Wire Rope)

No precise rules can be applied to wire rope replacement

because of the variables involved. Determining the condition

of the wire rope depends largely upon the judgment of a

qualified person.

The information below is excerpted from a National

Consensus Standard as referenced by Federal Government

Agencies and Manitowoc Crane Care recommendations to

help determine when wire rope needs to be replaced. Wire

rope shall be taken out of service when any of the following

conditions exist:

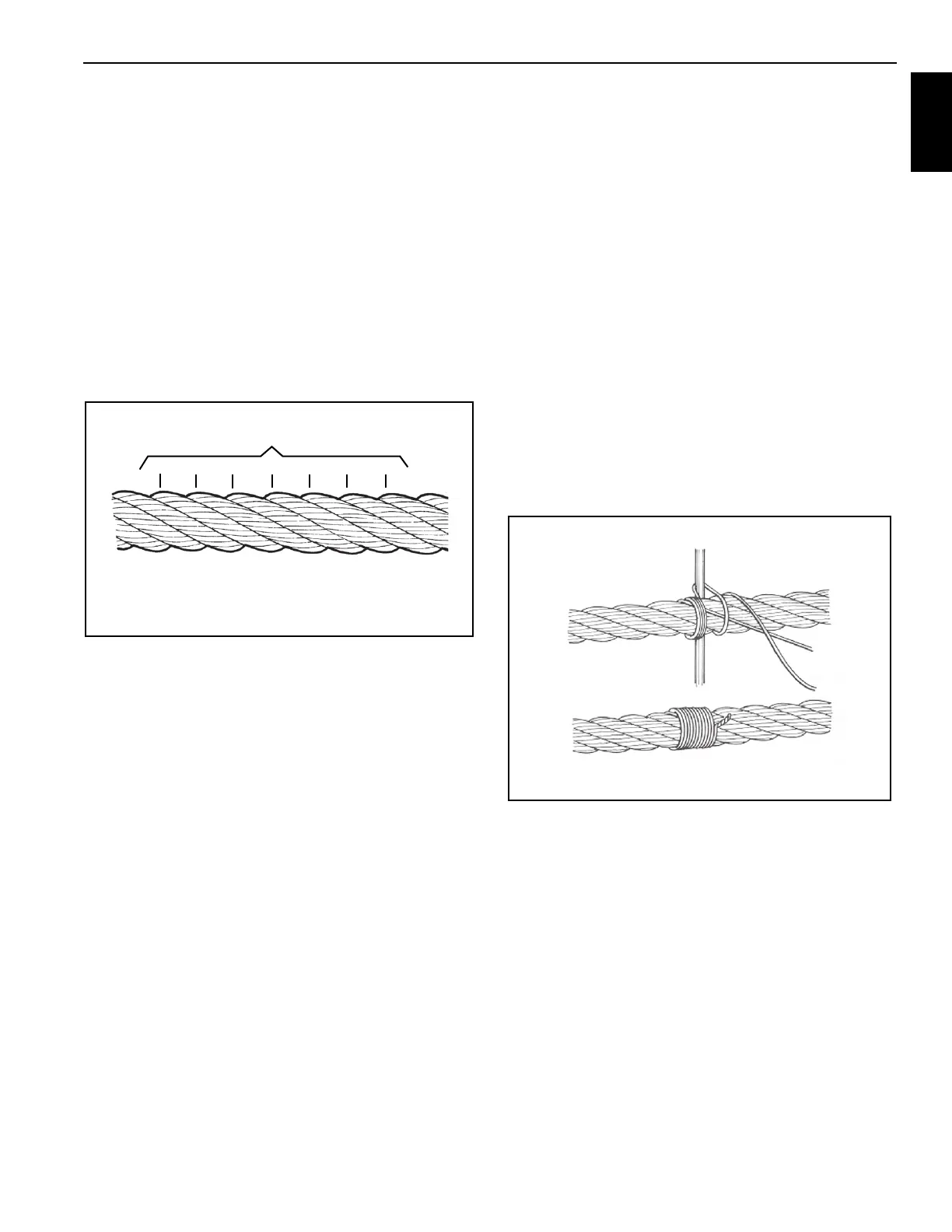

• In running ropes, six randomly distributed broken wires

in one lay or three broken wires in one strand in one lay

(Figure 1-6).

• In standing ropes, more than two broken wires in one lay

in sections beyond end connections or more than one

broken wire at an end connection.

• Wear of one-third the original diameter of outside

individual wires.

• Kinking, crushing, bird caging, or any other damage

resulting in distortion of the rope structure.

• Evidence of heat damage from any cause.

• Reductions from nominal diameter of more than 5%.

• Severe corrosion evidenced by pitting.

• In rotation resistant rope, two randomly distributed

broken wires in six rope diameters or four randomly

distributed broken wires in 30 rope diameters.

• National Crane recommends that for cable extended

booms, a single damaged wire rope assembly shall

require replacement of the complete set of extension

cables.

• National Crane recommends that boom extension

cables be replaced every seven (7) years.

Seizing Wire Rope

It is important to seize the ends of rotation resistant wire

ropes to prevent the displacement and unraveling of the

individual wires and strands at the ends. All preformed and

non-preformed styles of wire rope need to be seized prior to

cutting. Seizings must be placed on both sides of the point

where the wire rope is to be cut. The two methods for seizing

wire ropes are described below.

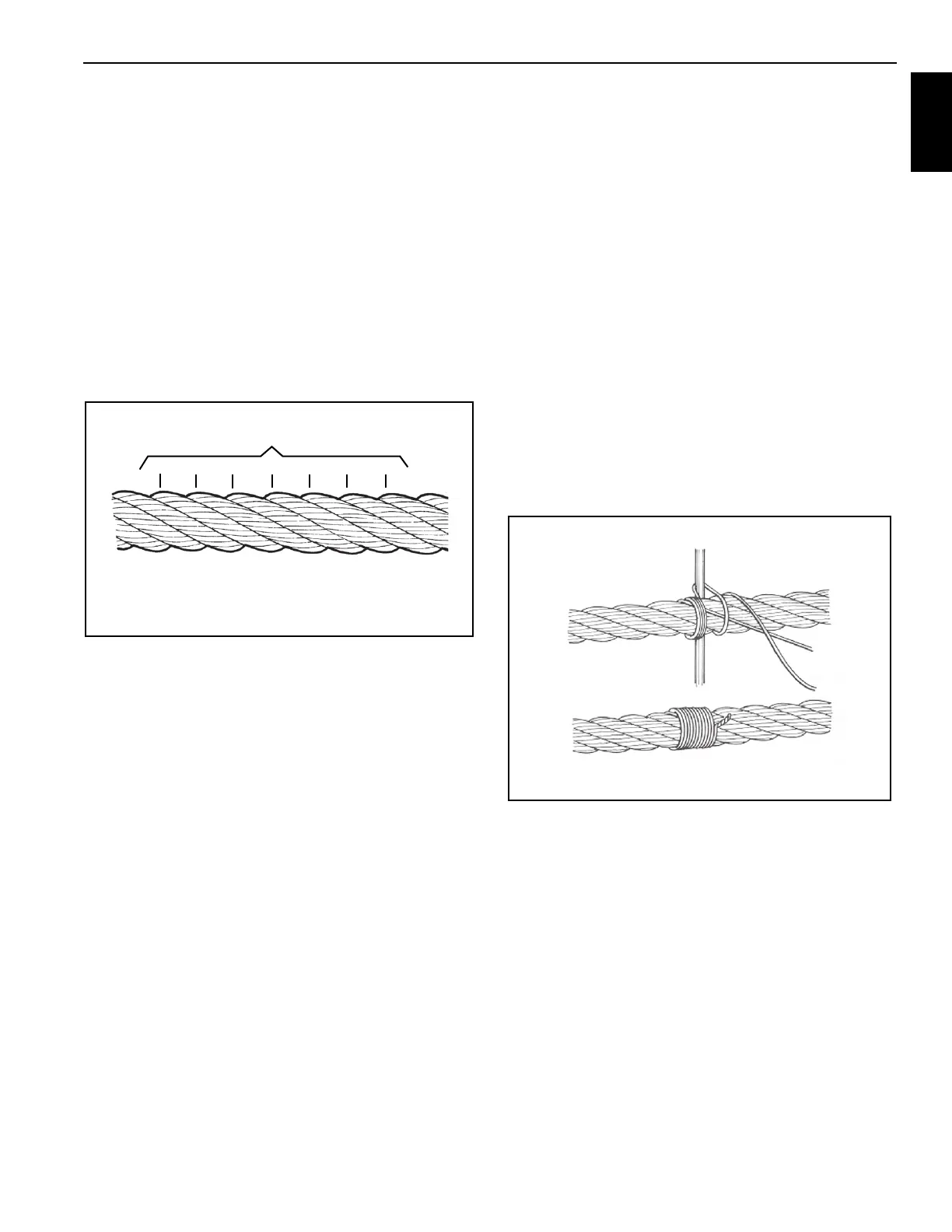

Method 1

Using a length of soft annealed wire, place one end in the

groove between two strands of the wire rope. Turn the long

end of the annealed wire at right angles to the wire and wrap

it tightly over the portion in the groove.

The two ends of the annealed wire should be twisted

together tightly. Cut off the excess wire and pound the twist

flat against the wire rope (Figure 1-7).

Method 2

Wind a length of soft annealed wire around the wire rope at

least seven times. Twist the two ends together in the center

of the seizing. Tighten the seizing by alternately prying and

twisting. Cut off both ends of the wire and pound the twist flat

against the rope (Figure 1-8).

6

1

2

3

4

5

6

One Lay

FIGURE 1-6

One lay is parallel to the rope center-line and is the

distance for one strand to make a complete spiral

around the rope.

Loading...

Loading...