2-4 Published 08/16/19 Control # 112-05

HYDRAULIC SYSTEM 500E2 SERVICE MANUAL

• To remove entrapped air from telescope cylinders, lower

the boom to below horizontal and fully telescope the

boom in and out several times.

• If the air is not readily removed, lower the boom to below

horizontal, extend the telescope cylinders as far as

practicable, and allow the boom to remain in this position

overnight. This should allow entrapped air to find its way

to the holding valve so that telescoping the boom IN the

next morning should force the air back to the reservoir.

Ensure the boom is first telescoped IN (not OUT) in the

morning. Telescoping OUT may cause air to be forced

back into the cylinder.

• Entrapped air may be removed from cylinders having

wet rods by cycling. On certain cylinders, a plugged port

is provided on the rod end to bleed off entrapped air.

• In the event that air entrapment should persist, bleeding

of air by loosening various clamp and screw type fittings

may become necessary.

• If the above procedures fail to eliminate air entrapment,

contact your authorized National Crane distributor.

Parts Replacement

Parts found damaged or out of tolerance when maintenance

is being performed should be replaced. Refer to the National

Crane Parts Catalog for proper replacement parts.

Maintenance Records

Dated records must be kept for inspection of critical

components such as, brakes, crane hooks, wire ropes,

hydraulic cylinders and relief valve pressure settings. These

records must be kept where they can be easily obtained and

reviewed.

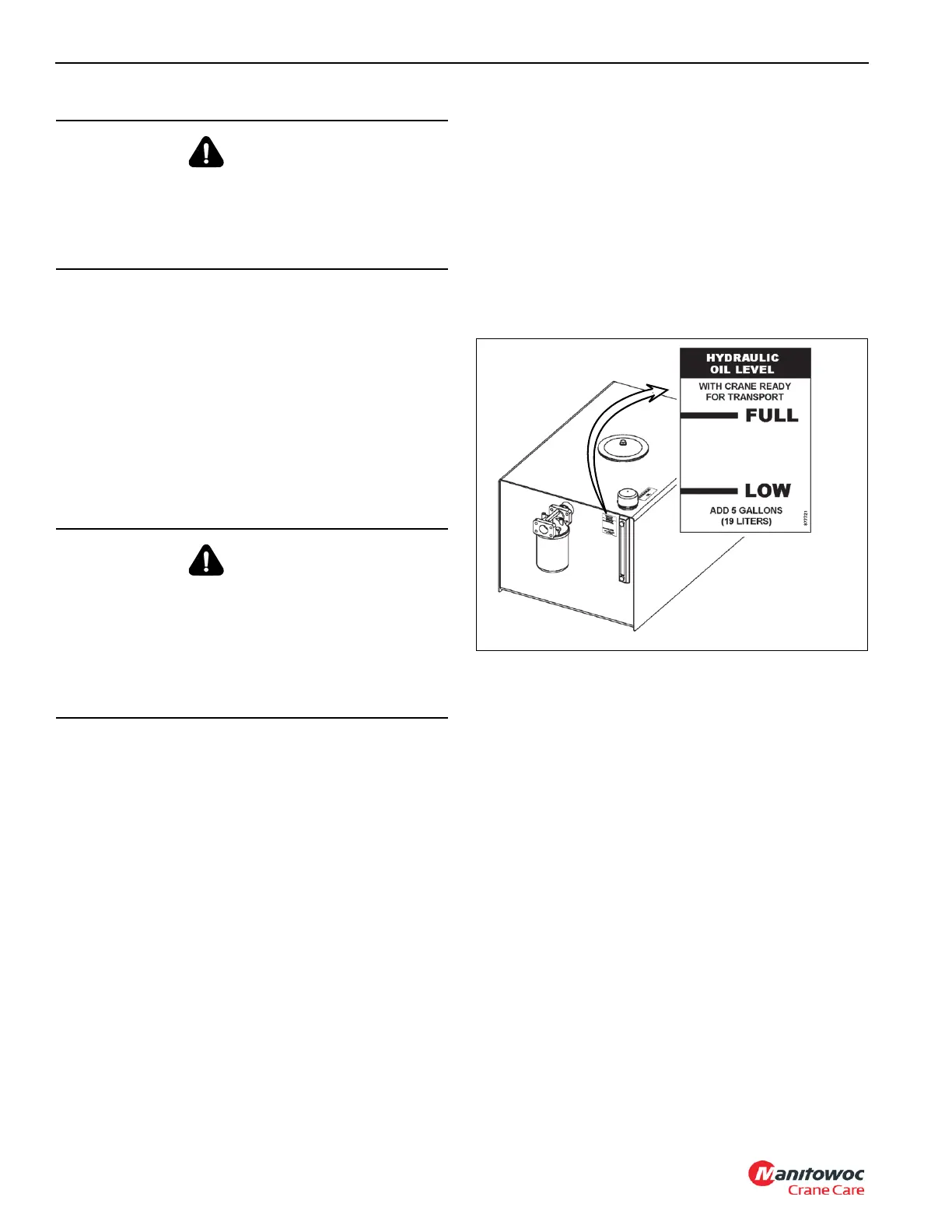

Hydraulic Oil Reservoir

The hydraulic oil reservoir has a sight gauge located on the

side of the reservoir. This sight gauge has a decal beside it

that indicates a “full” level and an “add oil” level. The oil

required to bring it from the “add” line to the “full” line is 5

gallons. Do not fill the reservoir above the “full” line. The oil

level should be checked with the crane parked on a level

surface, in the transport condition (all cylinders retracted and

boom stowed) and the oil cold.

Hydraulic Filter

Return oil filtration has been designed to handle the

maximum system flow and to protect the hydraulic system

components.

The filter is mounted on the oil reservoir, and is a replaceable

canister type return oil filter. The filter must be serviced with

National Crane replacement elements at recommended

intervals to assure the warranty remains in force.

Oil Cooler Service & Maintenance (Optional)

The heat exchanger must be kept clean to allow for efficient

operation of the cooler system. Frequent washing of the heat

exchanger core will eliminate oil film, road dirt and other

foreign object buildup on the heat exchanger fins which

reduces cooling efficiency.

Frequent inspection and tightening of hose clamp line

connections will eliminate the possibility of end connection

failure due to back pressure from cold startup.

If cooler system fails to provide adequate performance,

reduced air or oil flow through the heat exchanger is the

probable cause. The cooling fan should be inspected for

proper operation. Any obstructions to air flow should be

CAUTION

Always locate the machine on a firm supporting surface,

extend the outriggers and level the machine and position

the boom over the front to extend the boom at low angles.

Injury or damage to the machine may result if this caution

is not followed.

CAUTION

Do not attempt to loosen fittings in pressurized lines or

while the hydraulic pumps are in operation.

Extreme care must be used when removing any plugs or

restrictions from a hydraulic system suspected to have

entrapped air that may be pressurized. Moderate to minor

injury may result from pressurized air in a hydraulic

system.

Loading...

Loading...