INTRODUCTION 500E2 SERVICE MANUAL

1-22 Published 08/16/19 Control # 112-05

Environmental Conditions

The life expectancy of wire rope may vary due to the degree

of environmental hostility. Variation in temperature,

continuous excessive moisture levels, exposure to corrosive

chemicals or vapors, or subjecting the wire rope to abrasive

material can shorten wire rope life. Frequent inspections and

maintenance of the wire rope is recommended for preventing

premature wear and to insure long-term performance.

Dynamic Shock Loads

Subjecting wire rope to abnormal loads shortens the ropes

life expectancy. Examples of this type of loading are as

follows:

• High velocity movement followed by abrupt stops

(hoisting or swinging of a load).

• Suspending loads while traveling over irregular surfaces

such as railroad tracks, potholes, and rough terrain.

• Moving a load that is beyond the cranes rated capacity.

Lubrication

The object of rope lubrication is to reduce internal friction and

to prevent corrosion. New lubricant needs be added

throughout the life of the rope. It is important that lubricant

applied needs to be compatible with the original lubricant.

Consult the rope manufacturer for proper lubricant. The

lubricant applied shall be of the type which does not hinder

visual inspection. Those sections of rope which are located

over sheaves or otherwise hidden during inspection require

special attention when lubricating rope.

During fabrication, ropes receive lubrication which provides

the rope with protection for a reasonable time if stored under

proper conditions. After the rope is put into service, periodic

applications of a suitable rope lubricant are required. The

wire rope lubricant should have the following characteristics:

• Be free from acids and alkalis and should have sufficient

adhesive strength to remain on the ropes.

• Be of a viscosity capable of penetrating the interstices

between wires and strands.

• Not be soluble in the medium surrounding it under the

actual operating conditions (i.e. water).

• Have a high film strength.

• Resist oxidation.

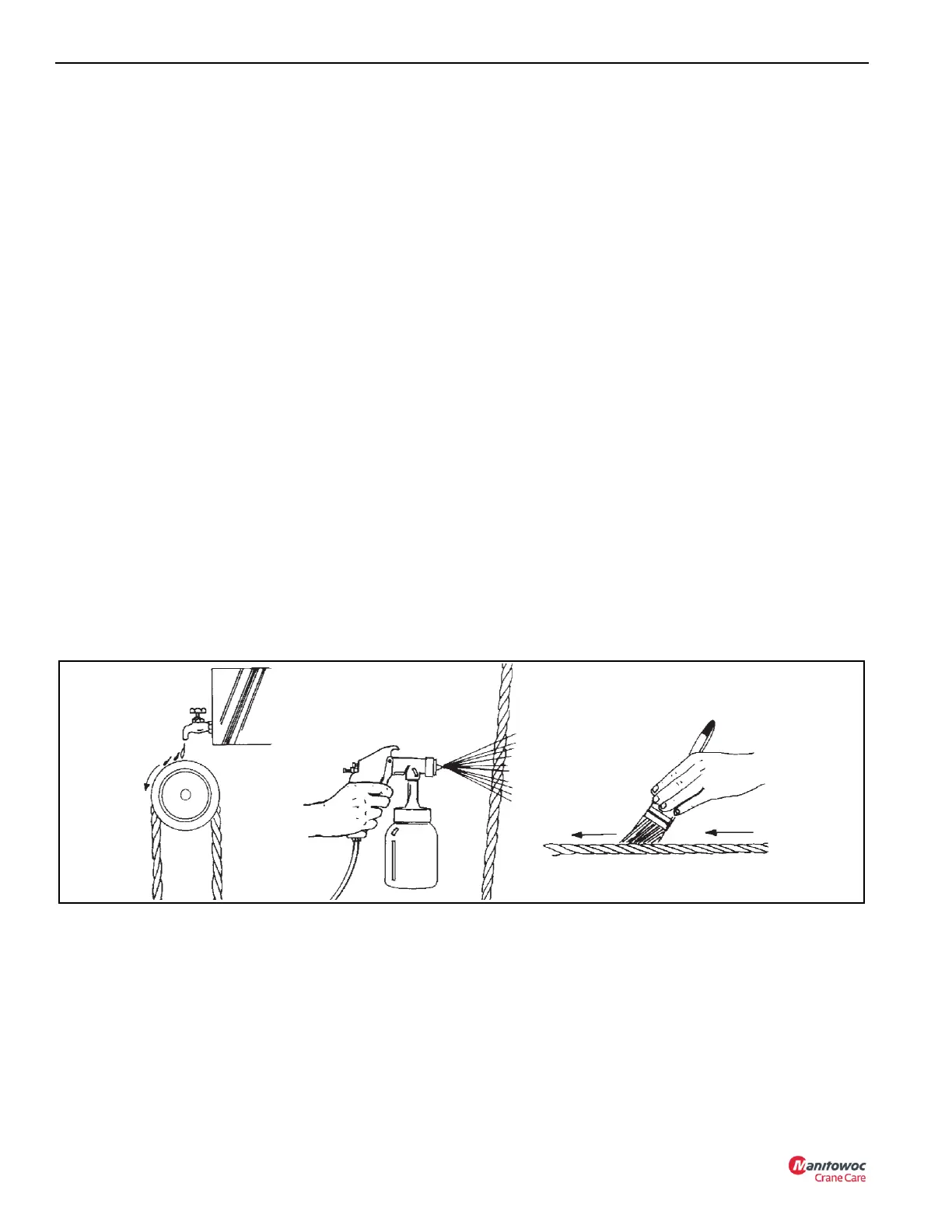

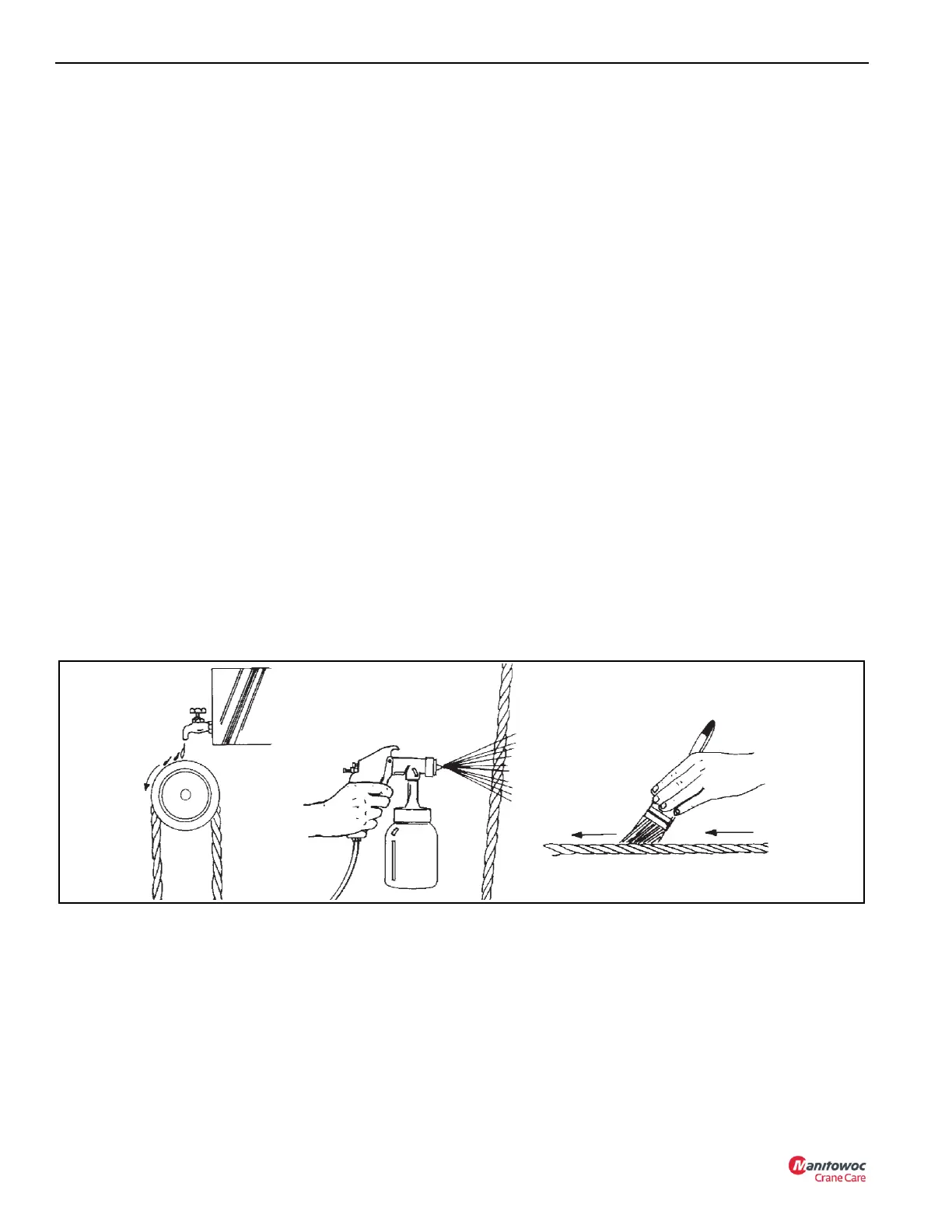

Remove dirt from the rope before applying lubrication. Use a

stiff wire brush and solvent, compressed air, or live steam to

clean the rope. Lubricate the rope immediately after

cleaning. Methods of lubrication are bath, dripping, pouring,

swabbing, painting, or pressure spray (Figure 1-4). Apply the

lubricant at the top bend in the rope because at that point the

strands are spread and more easily penetrated. Do not

lubricate a loaded rope. The service life of wire rope is

directly proportional to the amount of lubricant reaching the

working parts of the rope.

Precautions and Recommendations During

Inspection

• Always use safety glasses for eye protection.

• Wear protective clothing, gloves, and safety shoes as

appropriate.

• Measure the rope’s diameter across crowns of the

strands when determining if rope has become damaged,

refer to Figure 1-5.

Loading...

Loading...