National Crane Published 08/16/19 Control # 112-05 4-15

500E2 SERVICE MANUAL BOOM

break packing gland loose. Remove holding valve and

extend and retract plugs from butt plate and pull packing

gland out by hand.

7. As soon as the packing gland is sufficiently loosened,

properly support the rod assembly and carefully remove

it by hand. Place rod assembly on supports. Exercise

caution in the support and removal of the rod assembly

as damage to the chrome surface requires rod assembly

replacement.

8. Disassemble the piston set by removing nut, replace

worn or damaged parts.

NOTE: Note: Loctite 680 is used during original assembly

to secure nut to shaft.

9. If necessary, heat nut to 400-500° F (204-260°C) to

facilitate removal. If heat is necessary for removal,

discard nut and replace with new equivalent nut as well

as worn or damaged parts.

10. Wipe and inspect all cylinder internal and external

surfaces for damage.

11. Remove seals and bearings from packing gland and

piston. Replace all seals and bearings.

12. Inspect wear pad on barrel assembly and replace as

required.

Extend Cylinder Assembly

1. Reassemble shaft and piston set assembly in the proper

order with internal round section ring, assembled

packing gland, stop tube, piston to shaft o-rings,

assembled piston, and locknut. Loctite locknut onto

shaft using type 680 according to Loctite

recommendations. Torque locknut to 300 ft-lbs (407Nm).

2. De-burr ring groove edge in barrel assembly and inspect

all internal and external surfaces for damage.. Failure to

do so will damage packing gland and or barrel assembly

when packing gland is installed.

3. Grease piston assembly and install the shaft assembly

with piston, o-ring, stop tube, packing gland, internal

round ring into barrel assembly.

4. Using special drive tool, drive the packing gland into the

barrel assembly.

5. Insert one end of round ring into groove in barrel

assembly and spiral the ring into groove with straight

blade screw driver.

6. Cycle test cylinder to ensure no leaks exist. Support end

of cylinder as it extends and retracts.

JIB INSTALLATION AND ADJUSTMENT

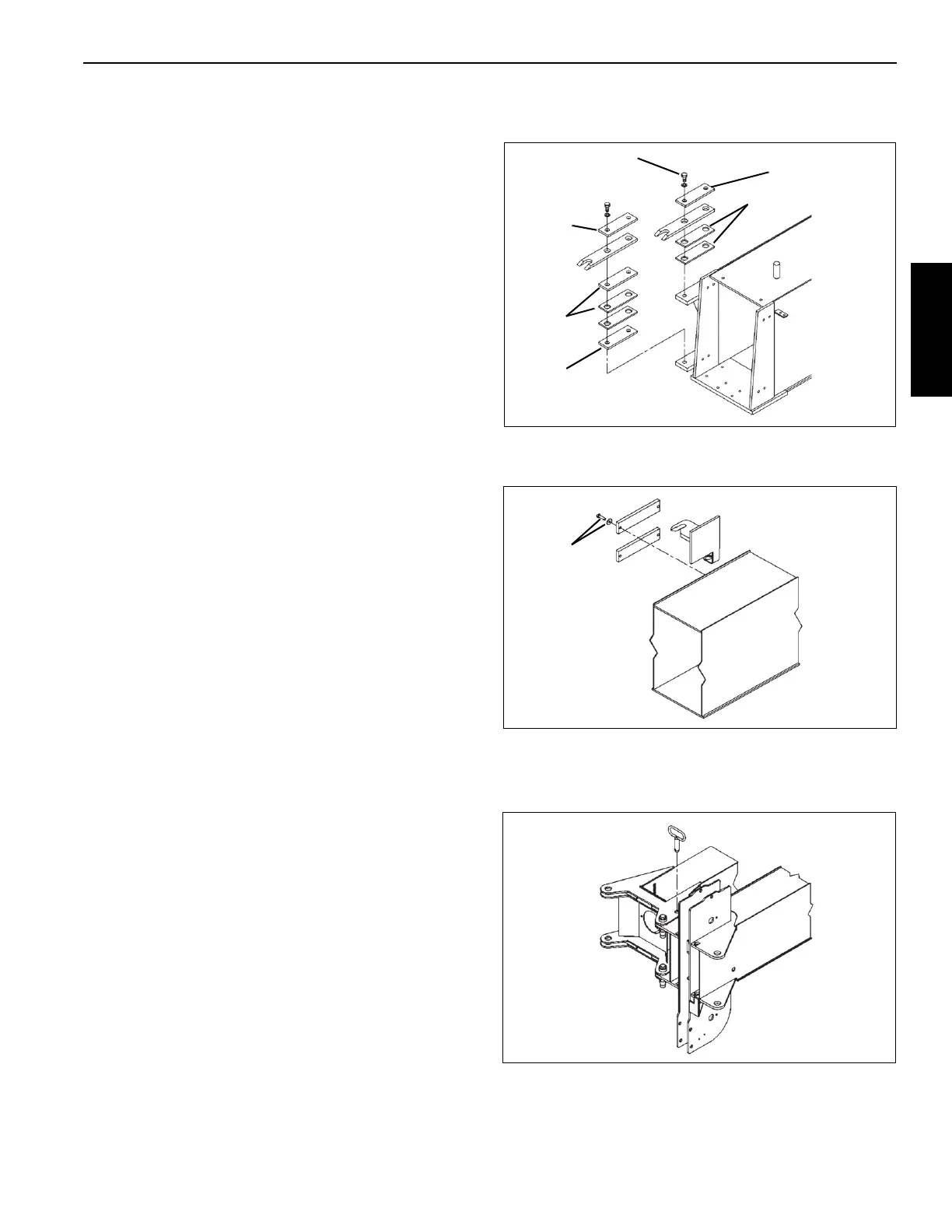

1. Loosely bolt the two ear assemblies with shims and bars

as shown to the side of the first boom section.

NOTE: Note: All measurements are in inches (mm).

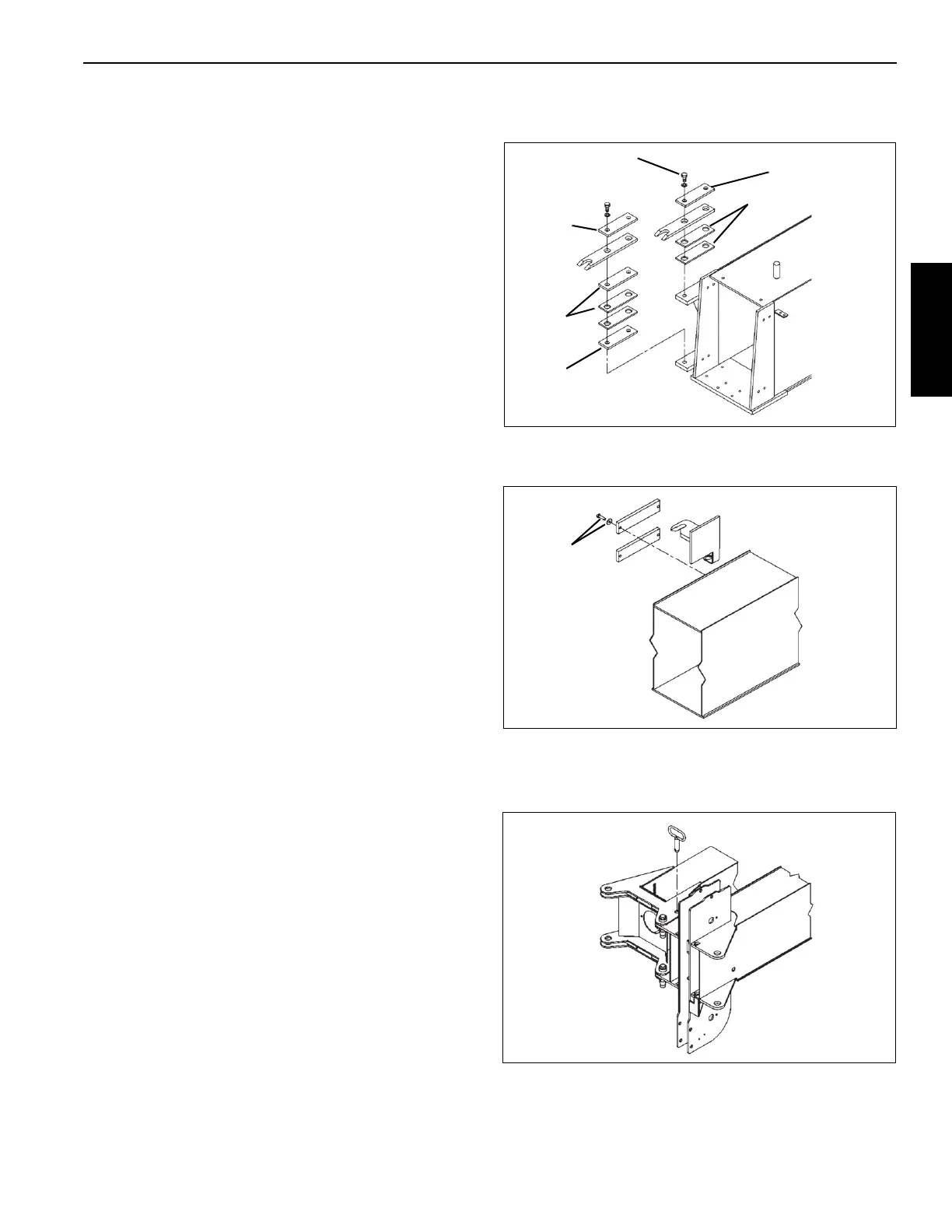

2. Loosely bolt the hook assembly to the side of the first

boom section.

3. Extend the boom approximately one foot (300 mm).

4. Using an overhead hoist, lift the jib assembly and align

and pin the jib to the boom sheave head.

5. With jib pinned to the sheave head, swing the jib parallel

to the boom and install the pin which keeps the jib from

3/4” Grade 5

(Typ 4 Plcs)

0.38 (10) Bar

0.38 (10)

Bar

0.06 (1.6)

Shims

0.38 (10)

Bar

0.06 (1.6)

Shims

Loading...

Loading...