National Crane Published 08/16/19 Control # 112-05 9-7

500E2 SERVICE MANUAL CRANE INSTALLATION

PTO HORSEPOWER REQUIREMENTS

The unit is equipped with a three section pump that supplies

34 GPM (129 LPM) to the hoist, 18 GPM (68 LPM) to the

boom and outriggers, and 10 GPM (38 LPM) to the swing

(turn) circuit. To provide these flows, the pump shaft must

turn at 2500 RPM. The PTO requirement is a torque rating of

at least 200 ft-lb (271 Nm) or 40 HP (30 KW) per 1000 RPM

of PTO shaft speed.

Direct Mount Pump to PTO

Most pump installations can be direct mounted to the PTO

using adapter assemblies available from the PTO supplier. If

the pump is direct mounted, its weight should be supported

by a strap between the pump and the transmission. The

splined shaft coupling in a direct mount pump installation

requires lubrication. #200S Silver Streak Special Multi-Lube

(Medium) needs to be applied to the shaft during original

installation and re-applied to the shaft or zerk provided on

PTO housing shaft semi-annually thereafter.

Pump Rotation

It is imperative that the three section hydraulic pump

installed in a 500E2 Service Manual application be the

correct pump rotation configuration for the truck drive train/

power take off rotation direction. Make certain which

direction the power take off output shaft rotates before

selecting a clockwise (cw) or counter-clockwise (ccw)

rotation hydraulic pump. Either cw or ccw rotation pumps are

available, and are marked clearly with a directional arrow on

the pump housing.

Do not confuse engine crankshaft rotation with power take

off rotation. If the power take off shaft rotates opposite the

engine crankshaft, it is turning in a clockwise (cw) direction

when viewed from the rear of the truck and if the power take

off shaft rotates the same as the engine crankshaft it is

turning counter-clockwise (ccw).

Operating speeds and performance of the crane are based

on proper pump outputs to the hoist, lift, telescope and swing

circuits. A triple pump system is standard equipment on the

600D. This pump supplies 34 (129), 18 (68) and 10 (38)

GPM (LPM) to the appropriate crane circuits when operating

at 2500 RPM.

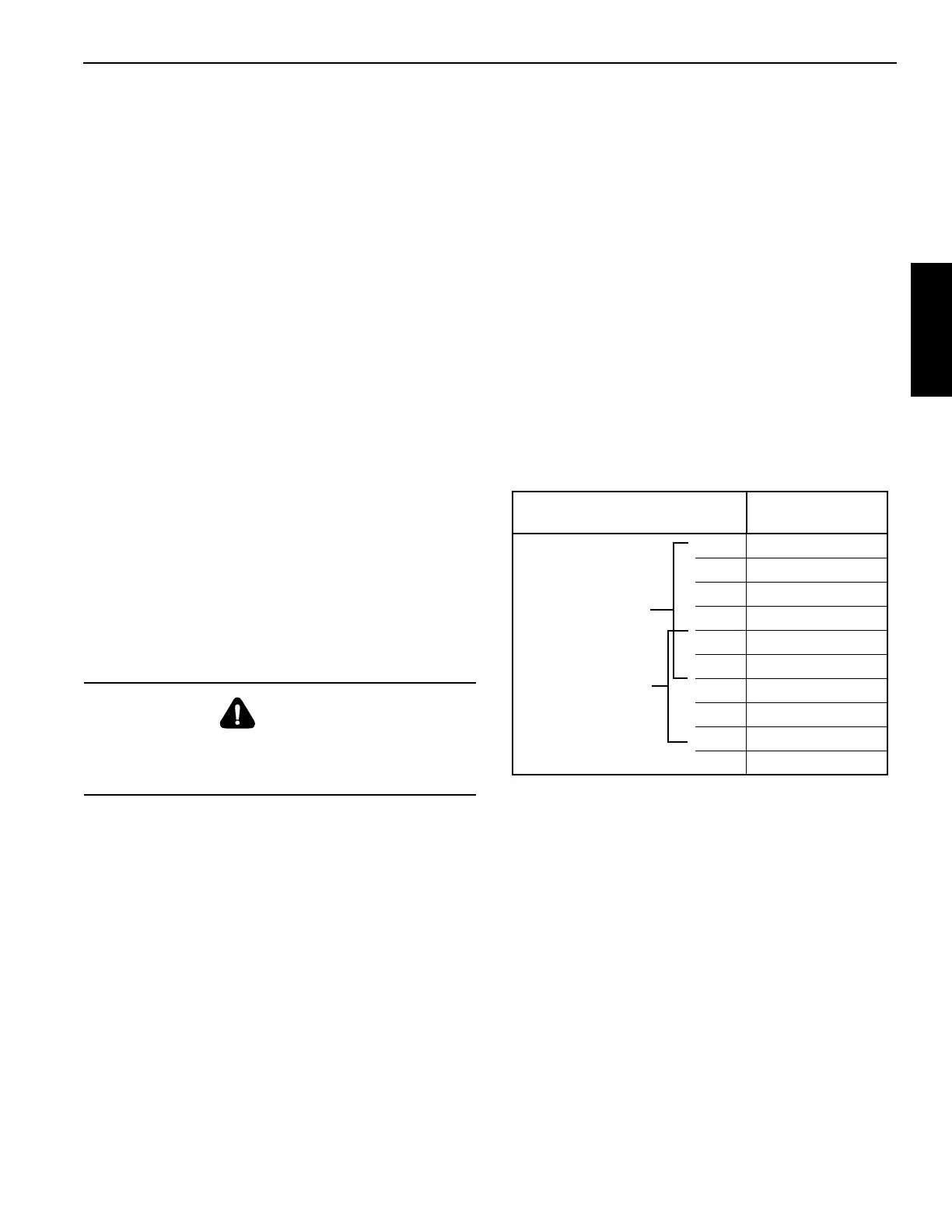

The speeds shown below are optimum operating speeds.

The engine must be operated at a speed such that the

horsepower developed is adequate to pull the pumps under

pressure.

See pump rotation section to determine correct pump for

your application.

CAUTION

To avoid pump failure, do not turn the pump in the

opposite direction of the indicating arrow on the pump

housing.

ENGINE SPEED

(RPM)

PTO RATIO

2400 RPM PUMP

2900 86%

2800 89%

2600 96%

2500 100%

2400 104%

2200 114%

2000 125%

1800 139%

1600 156%

1500 167%

Gasoline Engine

Optimum Speed

Range

Diesel Engine

Optimum Speed

Range

Loading...

Loading...