National Crane Published 08/16/19 Control # 112-05 8-5

500E2 SERVICE MANUAL TROUBLESHOOTING

Systematic Troubleshooting

The following step-by-step analysis will be helpful in isolating

and correcting almost every service problem if followed in a

step by step systematic manner. Use this information with

the Hydraulic Schematic and the Illustrated Parts Catalog to

identify parts and flow paths. Start at the top box and work

downward step-by-step. Do not try to start in the middle or

skip steps.

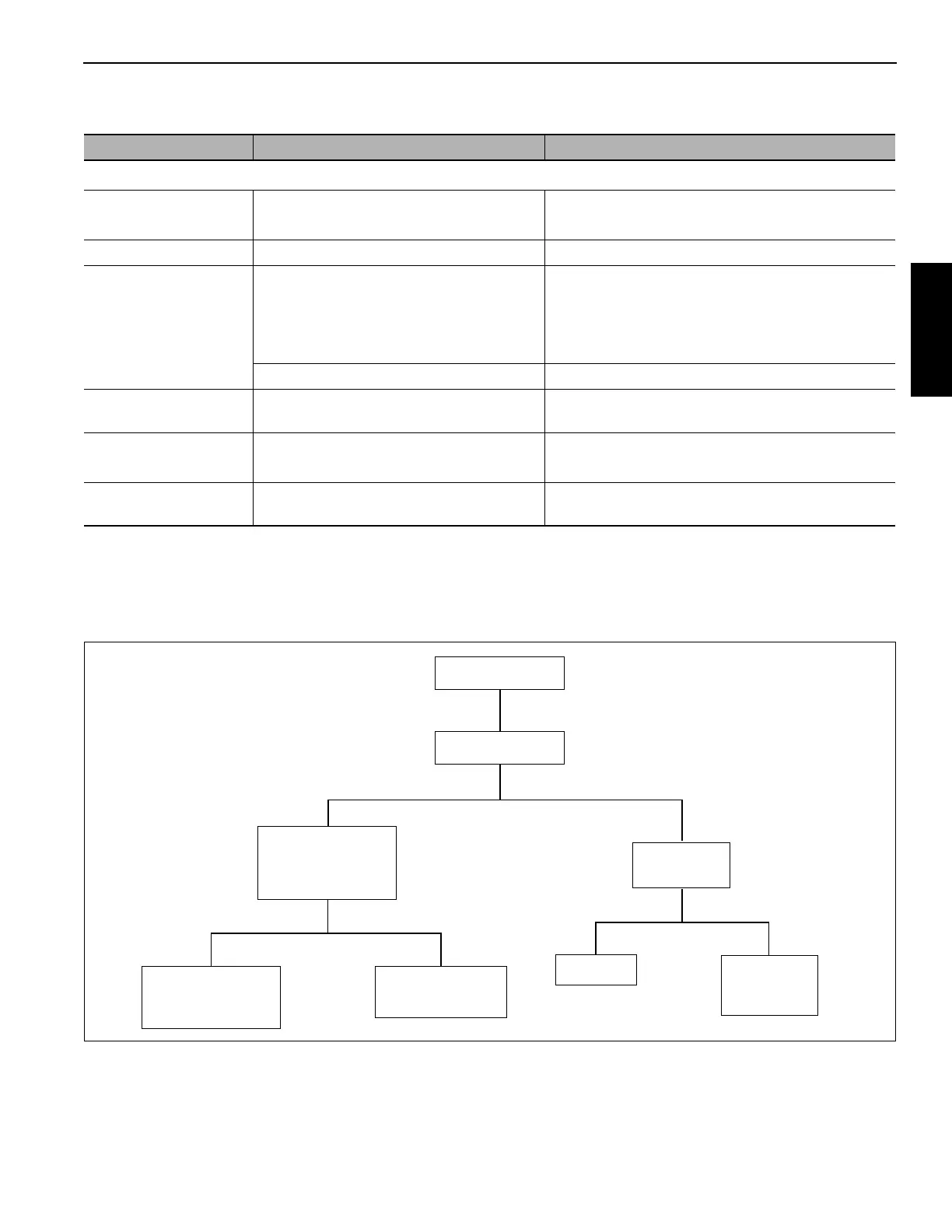

JIB JACK TROUBLESHOOTING

Does not lift load

No oil in system

Release valve not closed

Add oil to reservoir tank through oil filler hole

Turn handle clockwise tightly

Lifts load only part way Oil level low Add oil to reservoir tank through oil filler hole

Lifts load but does not

hold

The following valve or valves leaking

a. Suction valve

b. Delivery valve

c. Release valve

Replace jack

Packings worn or damaged Replace jack

Jack does not lower

Release valve stuck, probably dirt or

foreign matter

Transfer load then replace dirty oil, flush oil

reservoir with kerosene

Poor lifting

Dirty oil

Air in hydraulic system

Change hydraulic oil

Purge air from system

Poor pumping action

Oil seal for pump unit worn out or

damaged

Replace jack

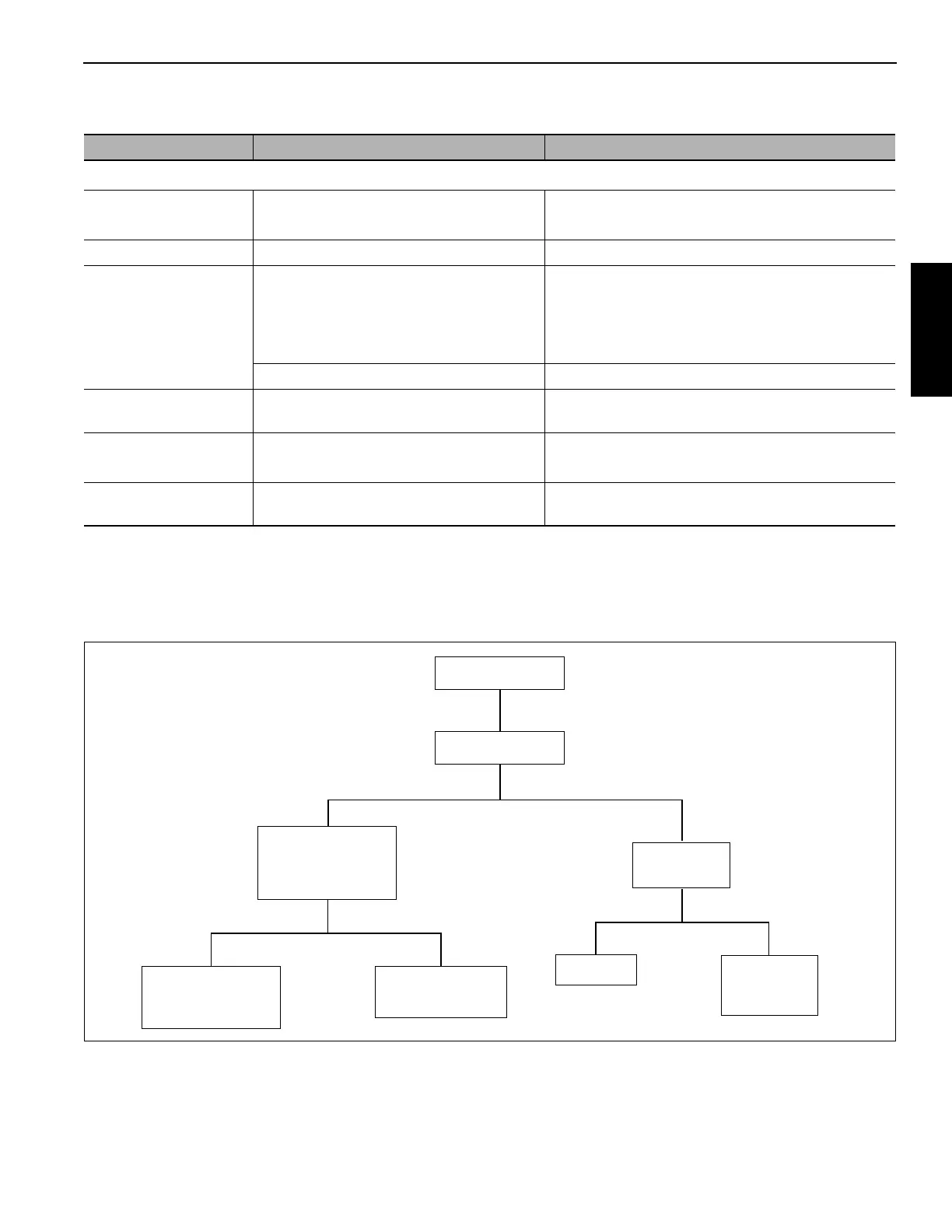

HYDRAULIC SYSTEM TROUBLESHOOTING CHART

Condition Possible Cause Possible Solution

Boom creeping down

Yes

No

Control valve in

meter in position.

Yes

No

Control Valve Centered

Cap sensing line between

the counterbalance valve

and the compensating

pressure switch.

Incorrect counterbalance

setting, bad counterbalance

valve, leaking cylinder seals

Replace compensating

pressure switch

Stops creep

Still creeps

Center valve

Control valve in

down position

normal operation

Loading...

Loading...