National Crane Published 08/16/19 Control # 112-05 3-5

500E2 SERVICE MANUAL ELECTRIC SYSTEM

.

9. When the pressure reaches capacity load pressure, the

overload system should activate and boom extension

will stop. This is defined as trip pressure. This point

should be at or very close to the red/yellow color change

on the load range gage.

10. Trip pressure should be reached as the boom extension

reaches the chosen radius. If the overload system trips

before the chosen radius is reached or allows extension

beyond the chosen radius, adjustment is required. If the

system is activated before trip pressure is reached,

lower the load and turn the knurled collar on the HCA

pressure switch clockwise to increase trip pressure.

11. When the gage reaches trip pressure, turn the setscrew

counterclockwise until the system solenoid is

deactivated and tighten the locking nut.

12. Retract the boom until the pilot pressure is reduced

enough to reactivate the system solenoid. The hydraulic

capacity alert indicator light will go out when the solenoid

is reactivated.

13. Check the trip pressure setting by extending the load

until the chosen radius is reached. As the chosen radius

is reached, the system solenoid should be deactivated

and the indicator light should come on. Readjust switch

head if trip pressure is not correct.

14. Once proper adjustment is verified, return the boom to a

firmly supported position, stop the truck engine and

replace covers.

JIB LOAD LIMITING DEVICE

The jib load limiting device is an electromechanical

maximum capacity sensing system that stops normal crane

functions which cause an overload condition when the

maximum capacity of the jib is exceeded. In the event that an

over capacity condition occurs, the jib load limiting device is

actuated by a load cell which causes the boom down, extend

out, and hoist up functions to become inoperative. On jibs

with a manually extendable section, a configuration switch

operated by the extension retaining pin distinguishes

between an extended jib and a retracted jib. This system

allows for continued operation of the hoist down, boom up,

and boom retract. This allows the operator to bring the load

to a shorter operating radius or set the load down in order to

eliminate an overload condition. Once the overload has been

reduced, normal operation can be resumed. This system

uses the work port unloader solenoid in the anti-two-block

system as the hydraulic system dump circuit.

When trip force is reached, the jib load limiting device breaks

electrical continuity to the work port unloader solenoid in the

main control valve. When power is removed from this

solenoid, the unloader valves allow the oil flowing to hoist up,

telescope out and boom down to flow to tank. This path to

tank will prevent further operation of these functions. When

the overload condition is corrected by hoisting down,

retracting the boom, or raising the boom, the jib load limiting

device allows the work port unloader solenoid to be powered

thereby allowing the crane to function normally.

During operation at near capacity loads, care must be taken

to operate the controls smoothly or the system may be

shocked into the dump mode prematurely.

Single Character Display

The electronics box of the jib load limiting devices equipped

with a single character display that provides the following

information:

• startup codes

• table number selected

• current load reading

• current limit value

• error codes

• current angle reading.

On power-up, the unit first displays the startup codes. The

startup codes can be a sequence of up to four single digits,

but is usually be only one digit which is a "2". Each number is

displayed for 1/2 second. The codes are:

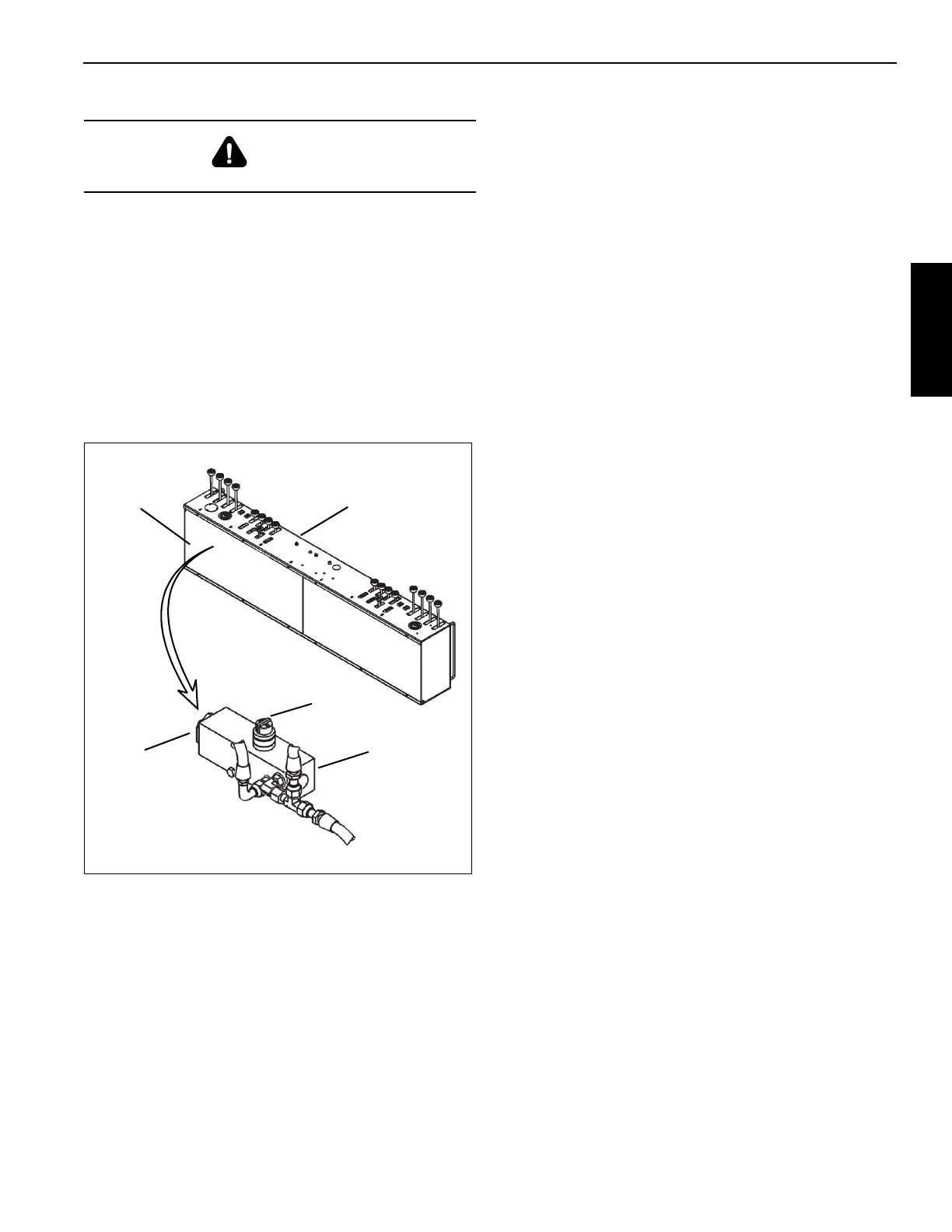

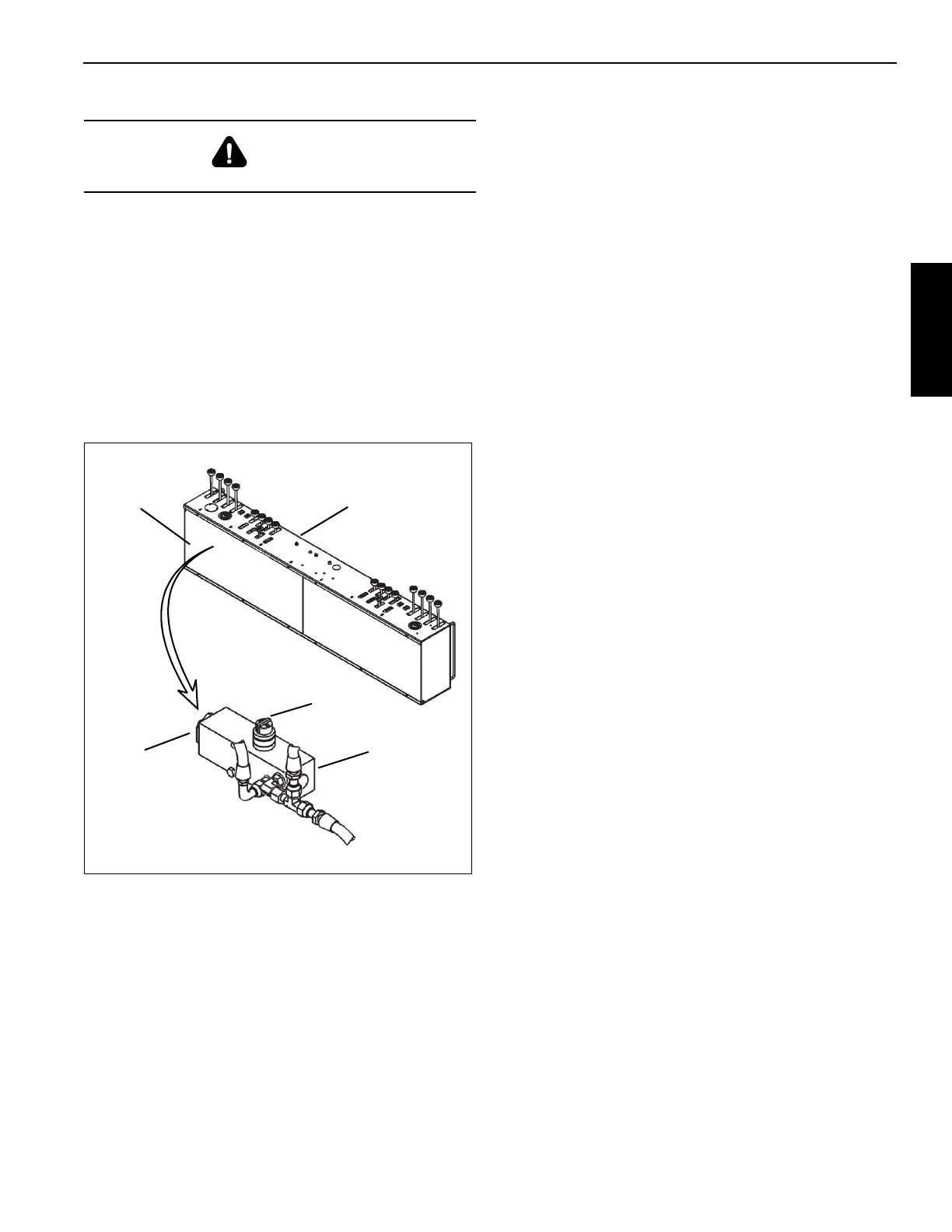

WARNING

Before loosening any fittings, support the boom.

Cover

HCA pressure

switch

Relief

Operators

Console

Adjustment

Knob

Loading...

Loading...