3-6 Published 08/16/19 Control # 112-05

ELECTRIC SYSTEM 500E2 SERVICE MANUAL

• (1) Indicates the unit is being initialized. This only

happens the first time the unit is powered up after it is

programmed.

• (2) Indicates that the previously stored table is being

erased. This is displayed when the unit is powered on

and the switches are not set for the new table numbers.

• (3) This is displayed only before a new table number is

stored. The “2” is displayed first.

• (8) The switches are set up with the new table number

and the old number is erased. On the next power on, the

new table number is read in and stored.

After the startup codes, the table number is displayed in the

form of three sequential single digits. The first digit is always

zero. The digits are be displayed for about 1 second each.

After the table number is displayed, the display starts to

sequence through the following information. After reaching

the end of the sequence, the display starts again at the

current load reading.

• Current load reading (lbs.):

- 4 digits, decimal point on

• Current limit value (lbs.):

- 4 digits, decimal point flashing

• Error codes (only if an error exists):

- 4 digits, first and last digits are blanks.

- 0-invalid table number,

- 1-load readings higher than the limit.

• Current angle reading:

- 4 digits, decimal point off, displays in tenths of

degrees.

Jib Load Limiting Device Troubleshooting

See chart in Section 8 of this manual.

OUTRIGGER MONITORING SYSTEM (OMS)

(OPTIONAL—STANDARD IN NORTH

AMERICA)

Operation

The Outrigger Monitoring System (OMS) aids the operator in

ensuring that the crane is properly setup on outriggers and

stabilizers. The OMS utilizes one sensor in each outrigger

and one proximity switch in each horizontally extending

stabilizer to identify when the outriggers and stabilizer beams

are extended to a point in which they provide maximum

stability.

Maintenance

Outrigger Cylinder Length Sensor

(Version 1)

Remove

1. Fully retract outriggers.

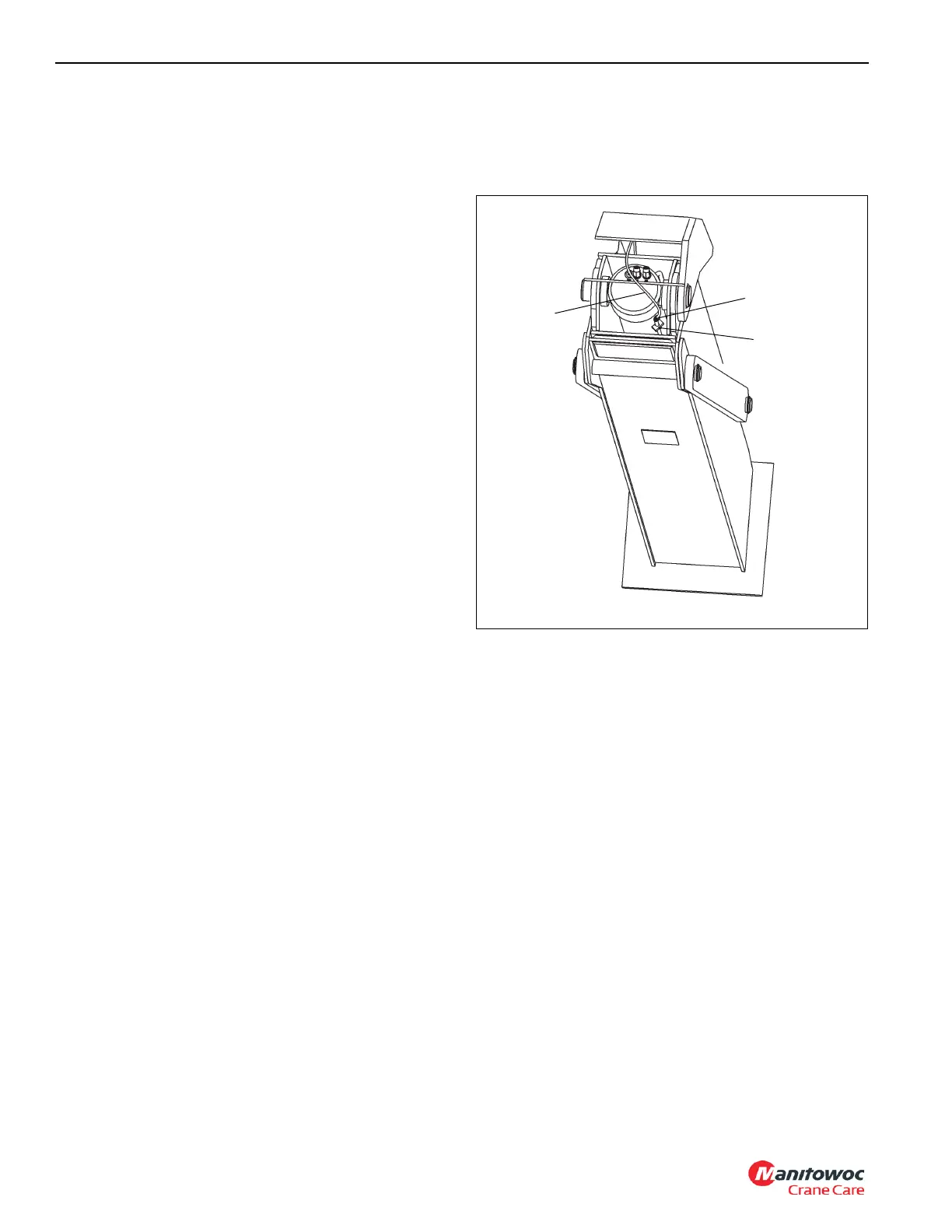

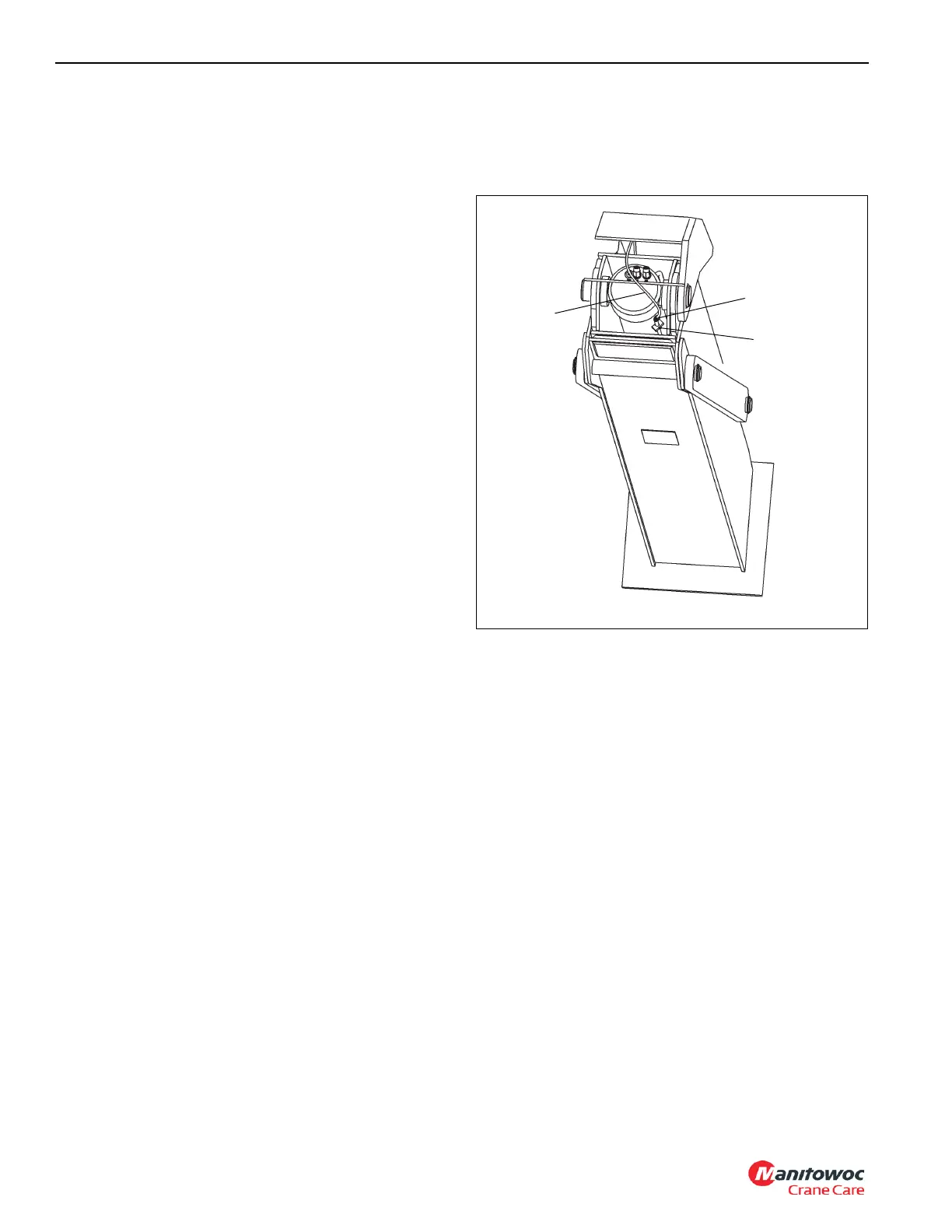

2. Disconnect electrical connector (1, Figure 3-1) at

sensor.

3. Remove setscrews (2, Figure 3-1) securing sensor

holding plate.

4. Slide sensor (3, Figure 3-1) out of sensor holding

bracket.

Install

1. Fully retract outriggers.

2. Slide sensor (3, Figure 3-1) into holding bracket.

3. Using the two setscrews (2, Figure 3-1) and sensor

holding bracket, secure sensor to the hydraulic cylinder.

4. Connect electrical connector (1, Figure 3-1) to sensor.

5. Calibrate sensor; refer to Calibrate, page 3-6.

Calibrate

Calibrating the cylinder length sensor requires a laptop

equipped with the HED Conductor software and a USB cable

connector (p/n 80009992). Contact your National Crane

distributor for further assistance.

Loading...

Loading...