National Crane Published 08/16/19 Control # 112-05 4-13

500E2 SERVICE MANUAL BOOM

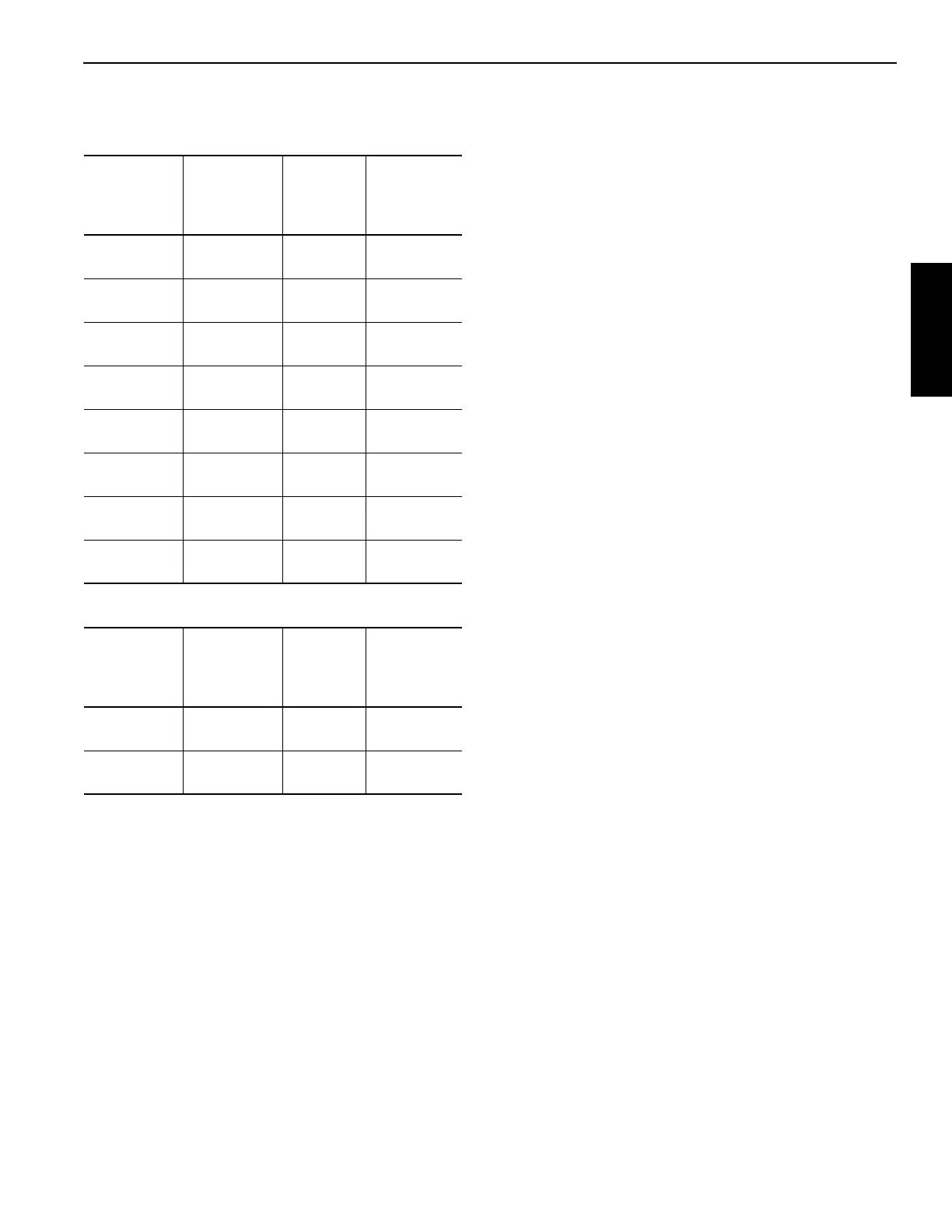

TORQUE VALUES for Second Nut:

Inch Series with Coarse Threads (UNC)

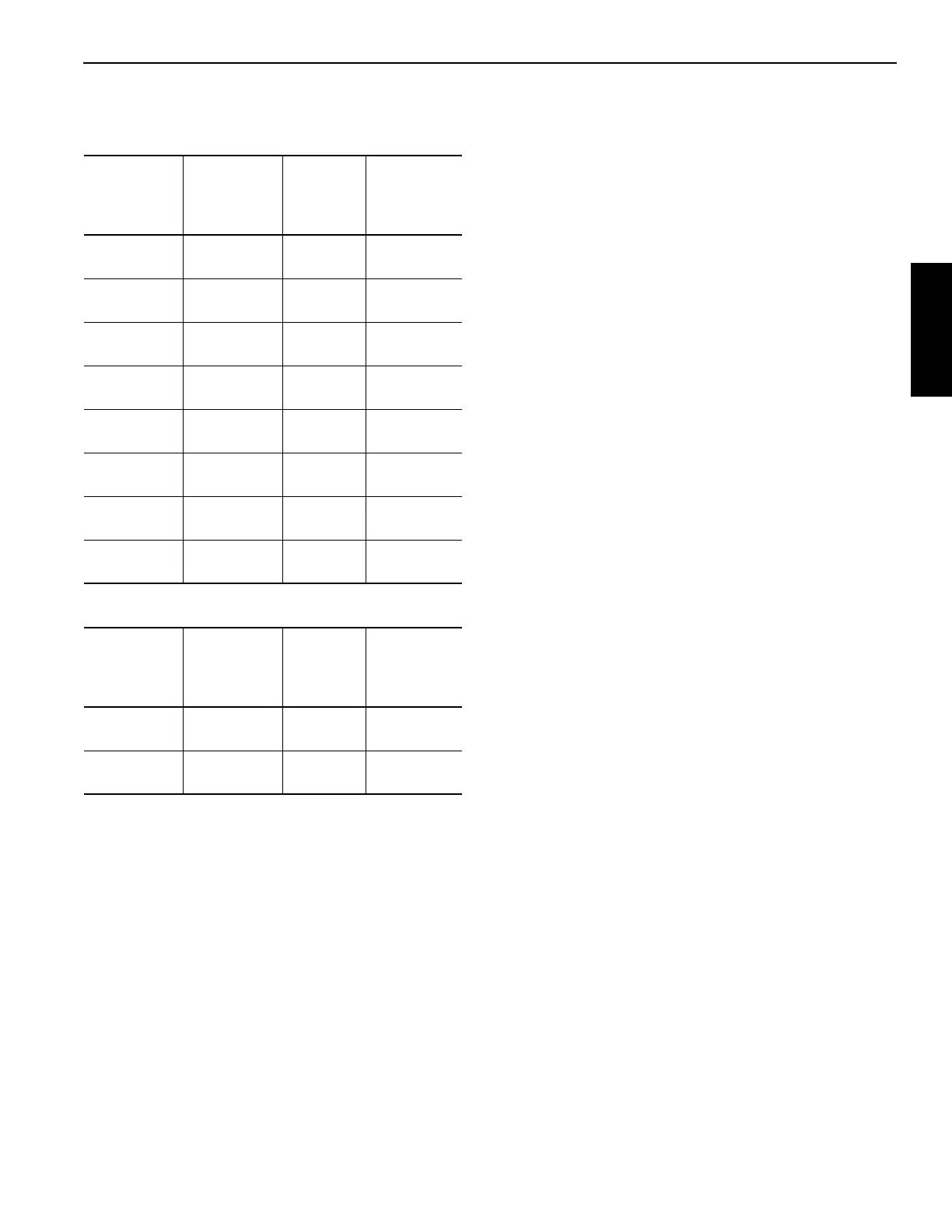

Metric Series with Coarse Threads

LIFT CYLINDER REPAIR

Lift Cylinder Disassembly

1. Disconnect shaft end of cylinder from machine.

2. Retract cylinder shaft with oil from the hydraulic system

until about 12 inches (30 cm) of shaft is extended. The

barrel must be filled with oil to prevent a compressed air

chamber being formed which could result in injury at

disassembly.

3. Remove the cylinder from the machine and place on

supports with an oil pan directly beneath the cylinder

head area.

4. Using the proper size of external snap ring pliers,

expand the snap ring completely and remove from

groove. Slide large washer forward to gain access to the

packing gland.

5. Using a special drive tool, drive the packing gland into

the barrel assembly to expose the round cross section

retaining ring. Then use a small needle nose locking

plier to clamp the round cross section retaining ring to

prevent it from rotating in the groove. Use two straight

blade screw drivers: one to pry the end of the ring out of

the groove and the other to pry the ring out of the barrel

assembly.

6. Attach a porta-power hand pump or hydraulic line from

crane circuit valve to the shaft end of the cylinder. De-

burr ring groove edge. Failure to do so will damage

barrel or packing gland.

7. Operate hand pump or crane circuit valve, preferably the

boom telescope circuit, to force packing gland out of

barrel.

8. Remove holding valve from cylinder to allow removal of

shaft and piston assembly. Remove the shaft and piston

assembly by hand.

9. Disassemble the piston set by removing nut, replace

worn or damaged parts. Note: Loctite 680 is used during

original assembly to secure nut to shaft. If necessary,

heat nut to 400-500° F (204-260°C) to facilitate removal.

If heat is necessary for removal, discard nut and replace

with new equivalent nut as well as worn or damaged

parts.

10. Wipe and inspect all cylinder internal and external

surfaces for damage.

11. Remove seals and bearings from packing gland and

piston. Replace all seals and bearings.

12. Reassemble shaft and piston set assembly in the proper

order with external snap ring, large washer, internal

round section ring, assembled packing gland, stop tube,

piston to shaft O.-ring, assembled piston, and locknut.

Loctite locknut onto shaft using type 680 according to

Loctite recommendations. Torque locknut to 600 ft-lbs

(813 Nm).

13. Grease piston assembly and install the shaft assembly

with piston, O.-ring, stop tube, packing gland, internal

round ring, large washer, and external snap ring into

barrel assembly.

Cable end

Thread Size

Minimum

Nut

Strength

GRADE

Nut Type

TORQUE

ft lbf

1/2-13 SAE 2

Hex Jam

(HALF)

12

5/8-11 SAE 2

Hex Jam

(HALF)

31

3/4-10 SAE 2

Hex Jam

(HALF)

47

7/8-9 SAE 2

Hex Jam

(HALF)

63

1-8 SAE 2

Hex Jam

(HALF)

199

1 ¼-7 SAE 2

Hex Jam

(HALF)

203

1 ½-6 SAE 5

Hex Jam

(FULL)

250

1 ¾-5 ASTM B

Hex Jam

(FULL)

250

Cable end

Thread Size

Minimum

Nut

Property

Class

Nut Type

TORQUE

Nm

M16x2 5

Hex Jam

(THIN)

26

M20x2.5 5

Hex Jam

(THIN)

66

Loading...

Loading...