National Crane Published 08/16/19 Control # 112-05 9-19

500E2 SERVICE MANUAL CRANE INSTALLATION

6. For a wet mount, a gasket is required for the mounting

flange to PTO gearbox interface. Dry mount does not

require a gasket.

7. Torque the mounting flange nuts to 50 ft. lbs (222 Nm).

NOTE: Some of the pipe fittings used are sealed by means

of two threaded tapered sections, one male and

one female. When these two tapers meet, you will

note a sudden increase in the force required to

screw the fittings together. This is true of all tapered

pipe threads. Further tightening will not only fail to

increase the pressure tightness of the joint, but

may ruin the connections and make correct

assembly impossible.

Other fittings are of the o-ring boss type. These are

installed by first screwing the lock nut flush to the

upper thread land and installing fitting into port until

the nut contacts the surface of the port. Adjust

fitting to desired direction. Tighten locknut.

Most pressure fittings are the O-ring face seal

types. A small O-ring is compressed between the

male and the female fittings of the joint. Be sure the

O-ring is present on the fitting and seated properly

in its groove before the fittings are tightened.

8. Remove the dust covers from the pump inlet and outlet

and make sure that the suction and pressure sides of the

pump are correct.

NOTE: An arrow is cast into the rear of the pump housing

to identify rotation. Make sure the rotation is

correct.

Rotate the pump in the direction as the PTO. Rotate the

pump in the mounting bracket so suction side is toward

the reservoir suction port.

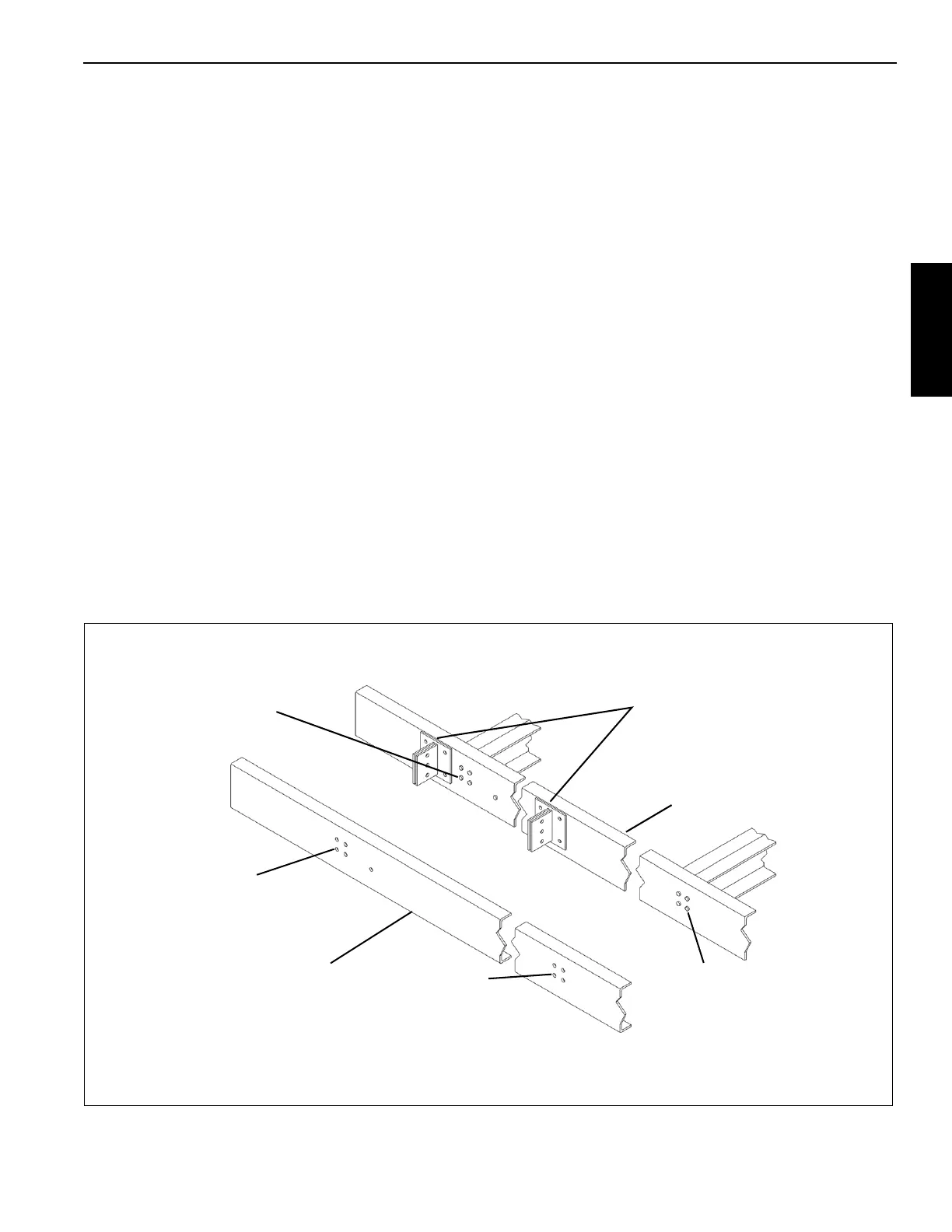

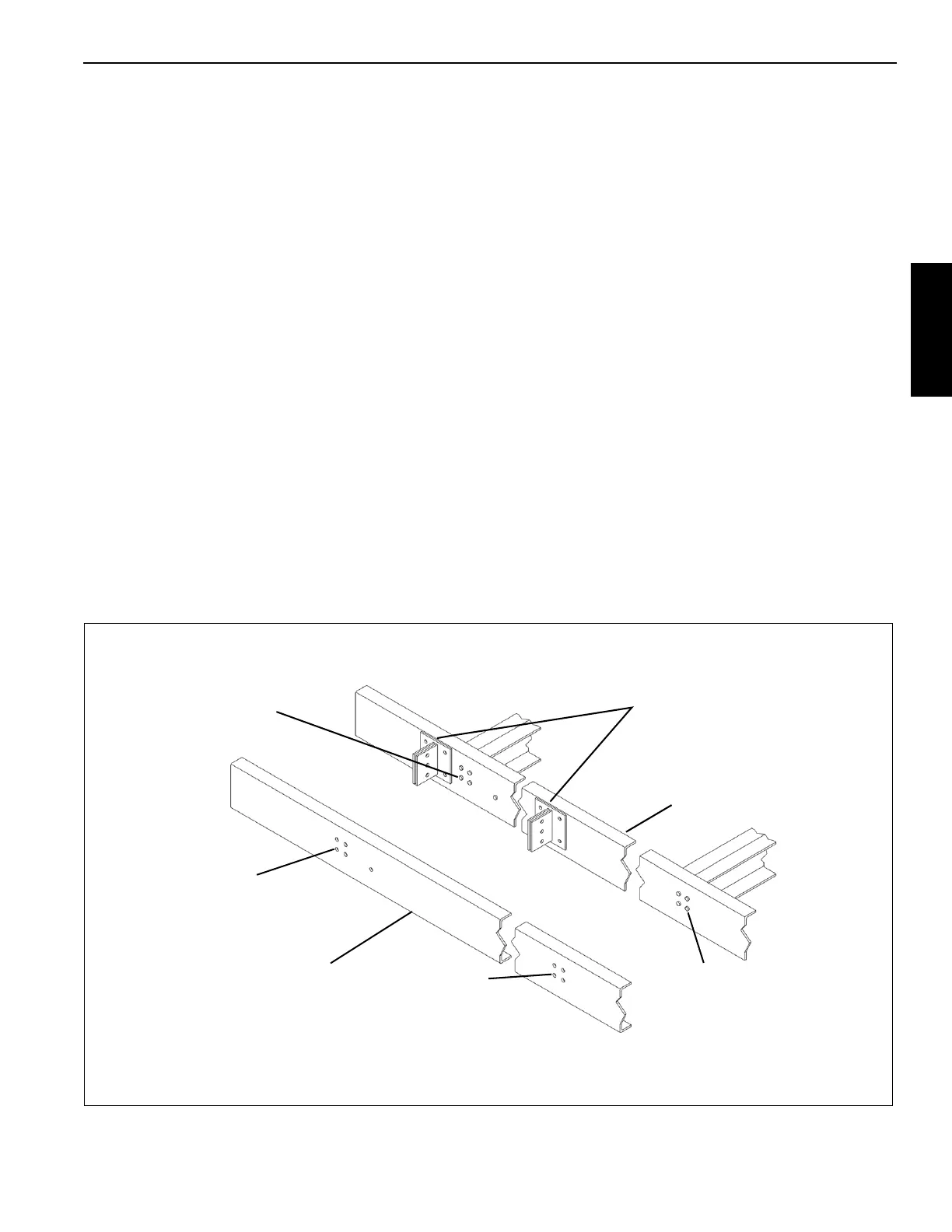

REINFORCING/AFTER FRAME EXTENSION

1. Refer to “Truck Frame Strength” and “Section Modulus”

tables. Determine section modulus by actual

measurement of the truck frame. If reinforcing is

required, always use at least 100,000 psi (758 MPa)

steel to minimize the amount of reinforcing required. Use

Grade 90 weld material for any welding to be done.

2. Strip the frame of obstructions in the area to be

reinforced or extended, one side at a time. If the truck

frame cross members are bolted in, remove the bolts.

Do not attempt to remove any rivets.

3. Place the reinforcing on the truck frame and clamp in

place. Mark the location of any rivets by striking the

outside of the reinforcing over the rivet area so that the

rivets make an impression on the inside of the

reinforcing. Mark the approximate location of the crane

mounting anchors so that no obstructions exist. Remove

the reinforcing and drill or torch cut clearance holes for

bolts or rivets. See Figure A.

The bolt hole clearance is

1/16 (1.52) to 1/8 (3.17) in

diameter larger than the

bolt shank

(Ref) Reinforcing

The rivet hole clearance

is 1/2 (12.7) in diameter

larger than the rivet head

Do not remove the rivets.

Clamp on reinforcing and strike

the reinforcing in this area to

mark the location of rivets

Remove bolts, clamp on

reinforcing, and mark the

bolt hole location from

the inside of the frame

Plan the location of the crane

mounting anchors so they don’t

interfere with the bolts, etc.

(Ref) Truck frame

NOTE: All dimensions

are inches (millimeters)

Figure A

Loading...

Loading...