9-20 Published 08/16/19 Control # 112-05

CRANE INSTALLATION 500E2 SERVICE MANUAL

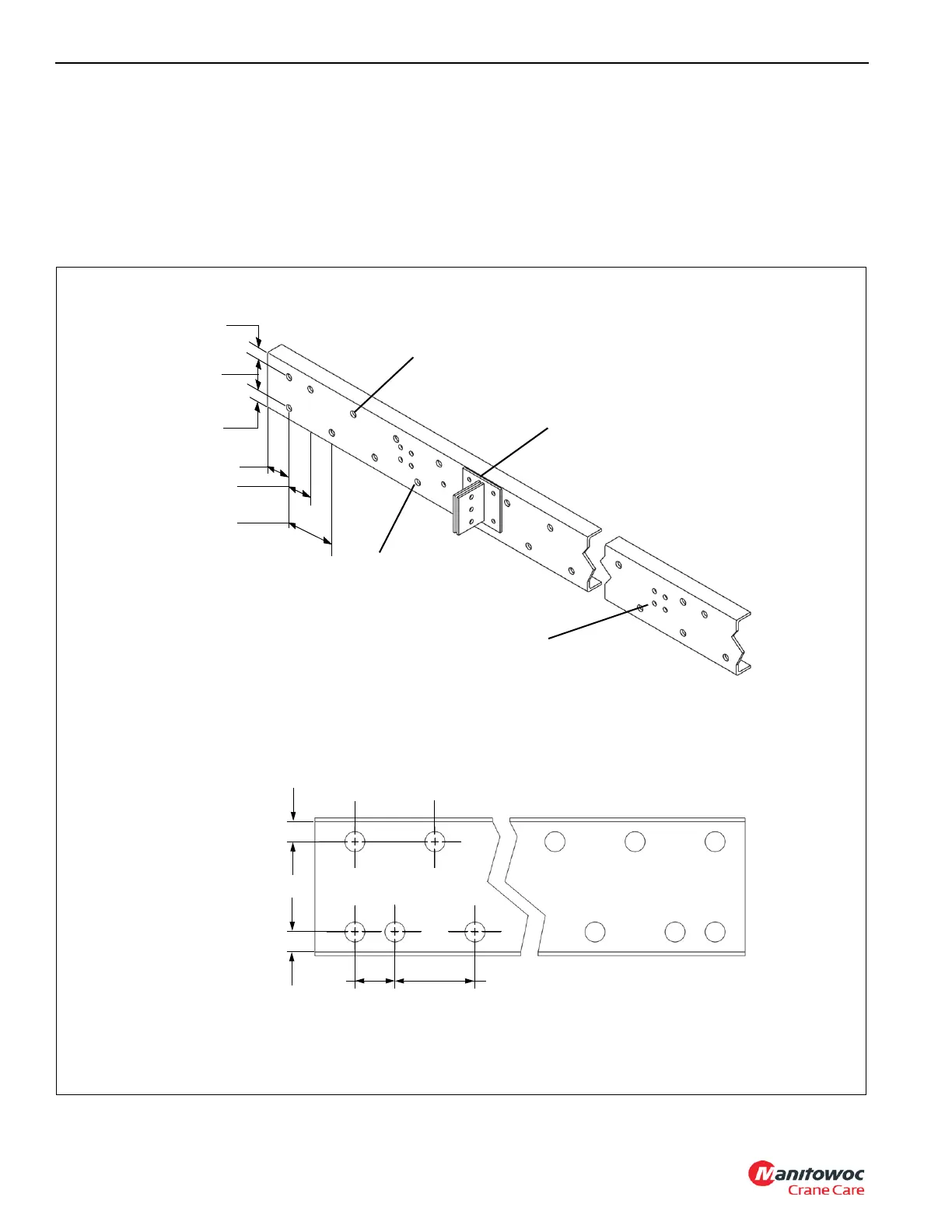

4. If reinforcing is to be welded on, torch cut hole pattern in

reinforcing being careful to clear crane mounting

anchors. Install reinforcing, clamp in place, install any

crossmember bolts that were previously removed and

weld to truck frame as shown in Figure B.

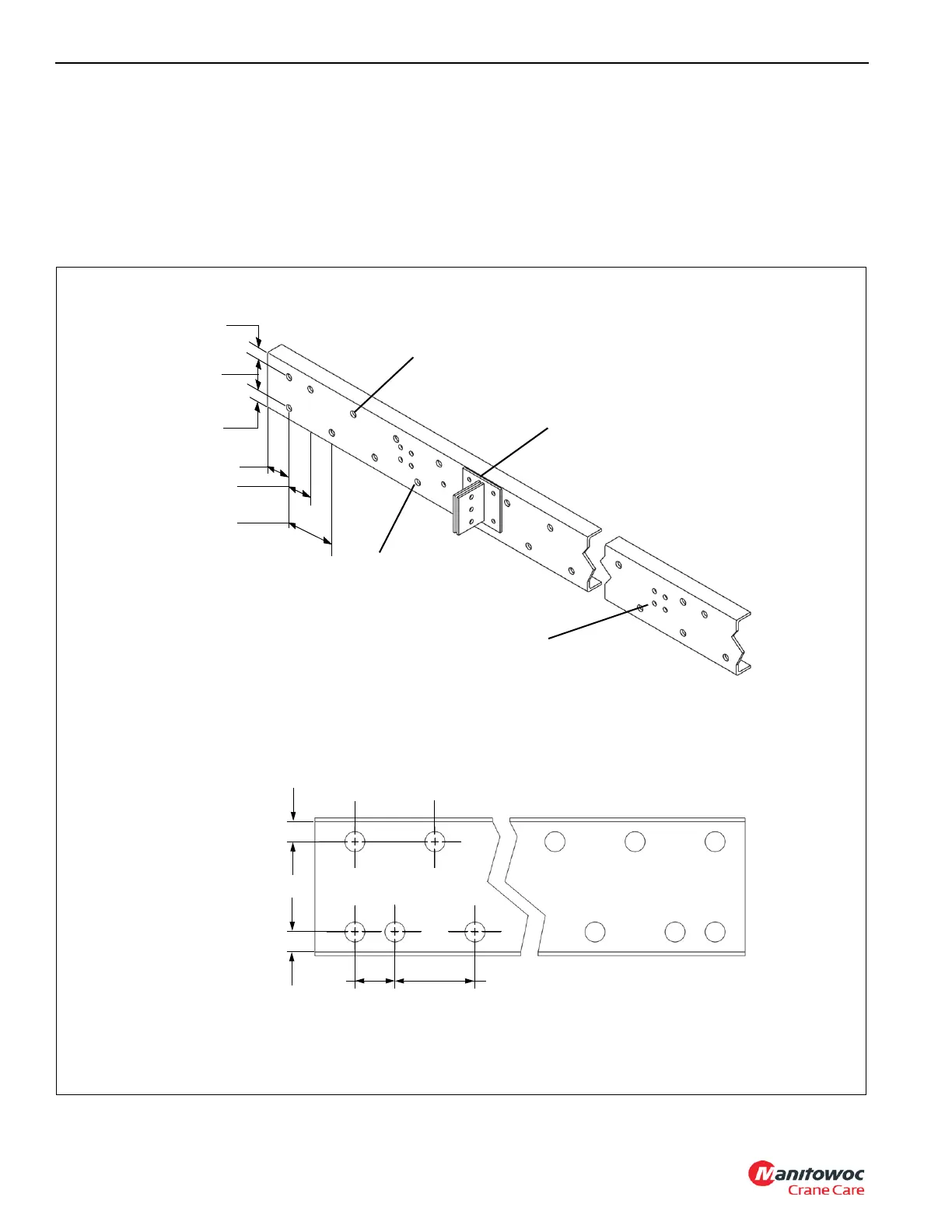

In some cases, because of customer stipulation or truck

manufacturer voiding their warranty, bolt-on reinforcing is

required. In these cases, install the reinforcing, clamp in

place, install any crossmember bolts that were previously

removed, then drill through reinforcing and truck frame being

careful to clear crane mounting anchors and bolt reinforcing

in place. See Figure C for recommended drilling and bolting

procedure. Use 5/8, Grade 8 bolts, drill holes to 39/64

diameter, drive fit bolts and torque according to "Torque

Values For Grade 5 and 8 Bolts" table in Section 2.

Crossmember bolt holes

plug weld. Holes can be

shifted slightly to clear.

4 (101)

4 (101)

8 (203)

2 (51)

5 (127)

2 (51)

1 (25.4) diameter

holes for plug welds

Planned location of mounting

plate. Plug weld locations can

be shifted to clear plate.

Clearance holes for rivets on weld or

on reinforcement. Can be filet welded

around to eliminate plug weld holes.

8 (203) Typ

4 (101)

2 (51) Min

2 (51) Min

NOTE: All dimensions are inches (millimeters)

Figure B

Figure C

Loading...

Loading...