NOTICE

Water trapped in the seawater section of the cooling system can cause corrosion or freeze damage. Drain the seawater

section of the cooling system immediately after operation or before any length of storage in freezing temperatures. If the boat

is in the water, keep the seacock closed until restarting the engine to prevent water from flowing back into the cooling system.

If the boat is not fitted with a seacock, leave the water inlet hose disconnected and plugged.

IMPORTANT: Lubricate all moving engine components with clean engine oil or other specified lubricant during assembly.

Torque Specifications

External Engine Components

Description Nm lb‑in. lb‑ft

Alternator mounting fasteners 27 – 20

Engine coolant temperature (ECT) sensor 16.3 144.2 –

Engine mount, front bracket 62 – 45.7

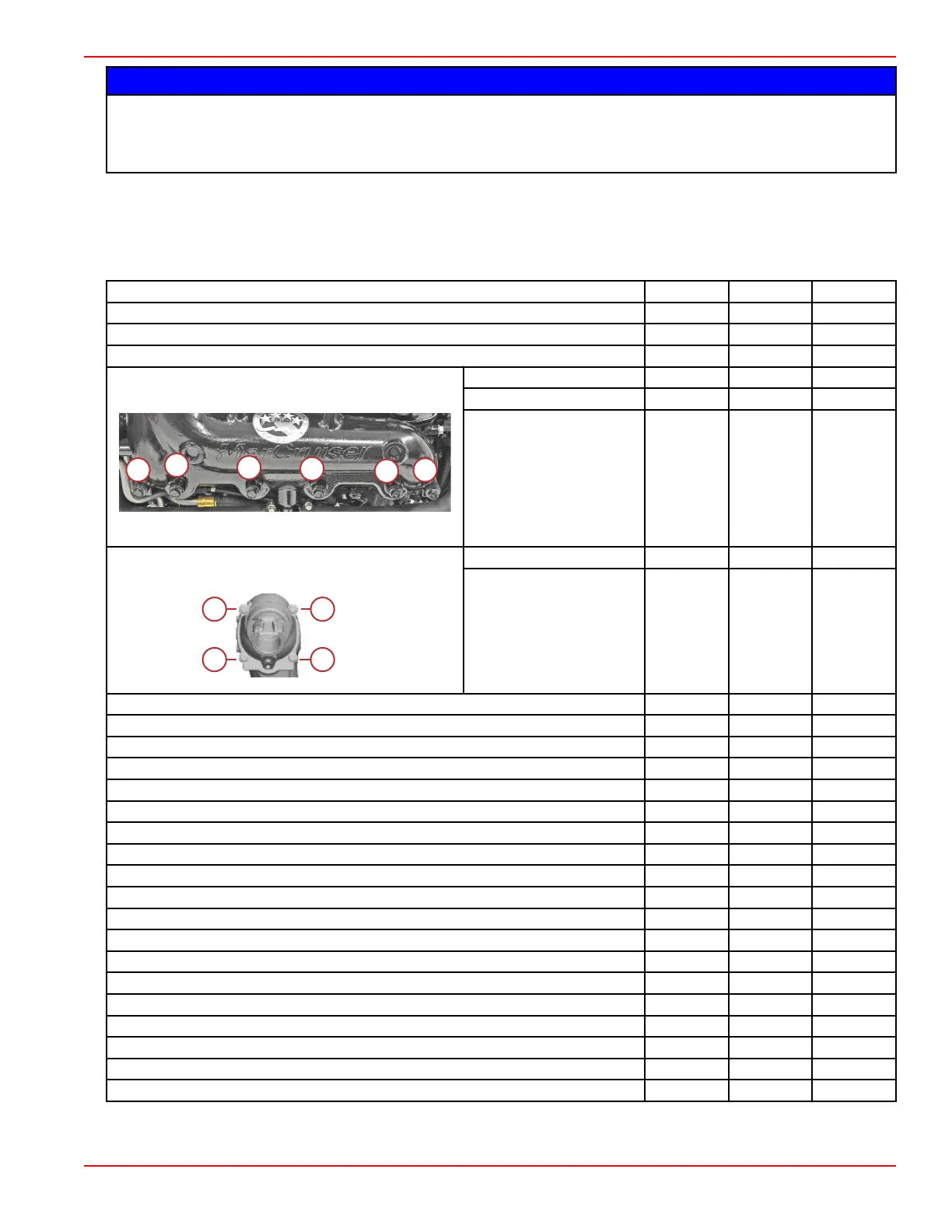

Exhaust manifold screws—use torque sequence listed

for each pass

First pass 27 – 20

Second pass 54 – 39.8

Final pass 54 – 39.8

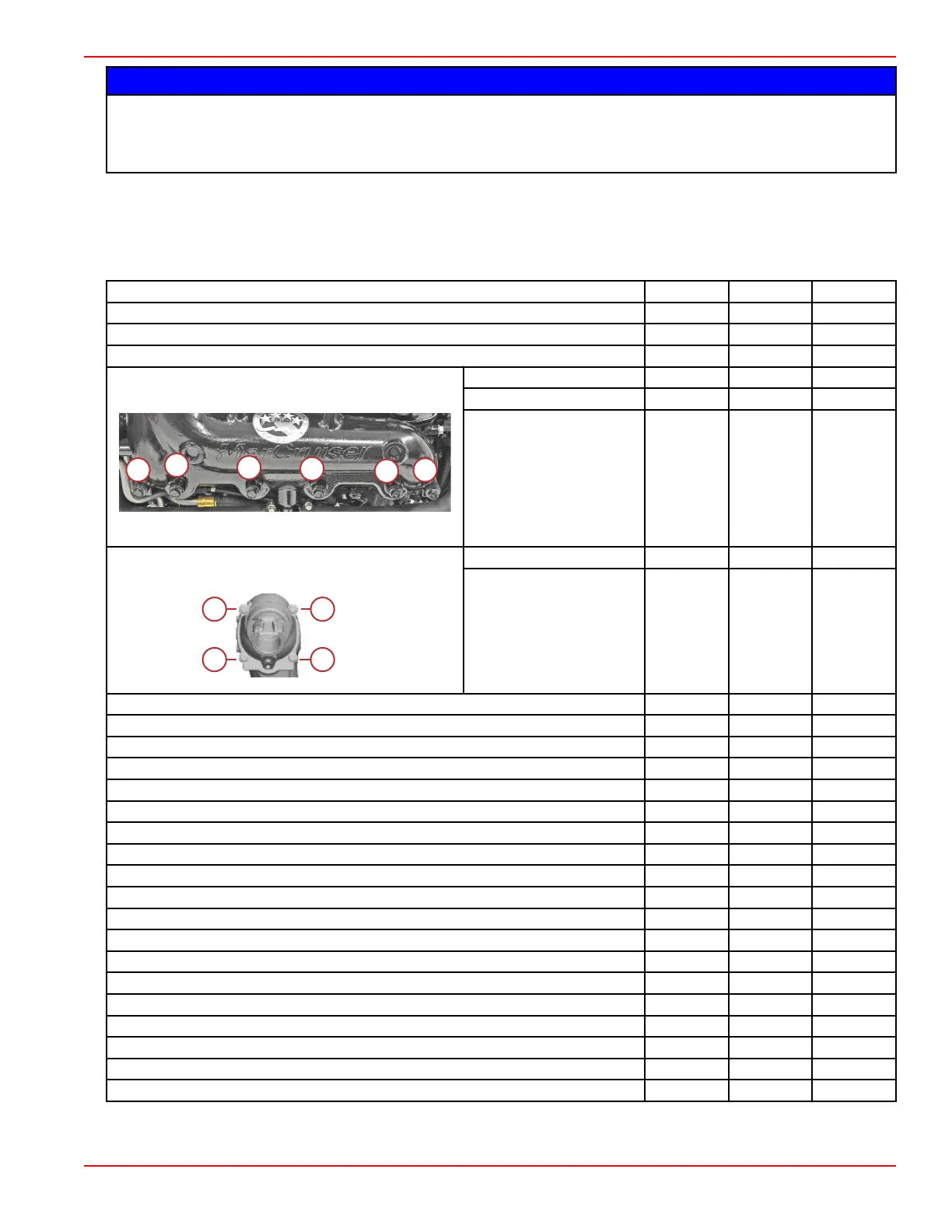

Exhaust elbow screws—tighten screws using an

X‑pattern, use torque sequence listed for each pass

First pass 46 – 33.9

Final pass 46 – 33.9

Fuel rail bracket screws 12.2 108 –

Coil to coil bracket screws 4.5 39.8 –

MAPT sensor screw 7 61.9 –

Seawater pump bracket to block 40.6 – 29.9

Seawater pump bracket to block—steel stud/nut 67.7 – 49.9

Starter motor screws 47.5 – 35

Engine flywheel screws 80 – 59

Engine block coolant drain hole plug 20 177 –

Flywheel housing studs and screws 50 – 36.9

Flywheel housing cover 9 79.6 –

Oil drain plug 24 – 17.7

Oil pressure sensor—top of engine 17 150.4 –

Oil line to oil filter base screws 13.1 115.9 –

Oil pump cover screw 10.5 92.9 –

Thermostat cap to crossover screws—standard and closed cooling 27 – 20

Crossover to head screws—standard and closed cooling 27 – 20

Throttle body screws 11 97.3 –

Water circulating pump fasteners—3 screws, 1 stud 29 – 21.4

Water pump pulley screws 27 – 20

Engine Disassembly

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 3A-5

Loading...

Loading...