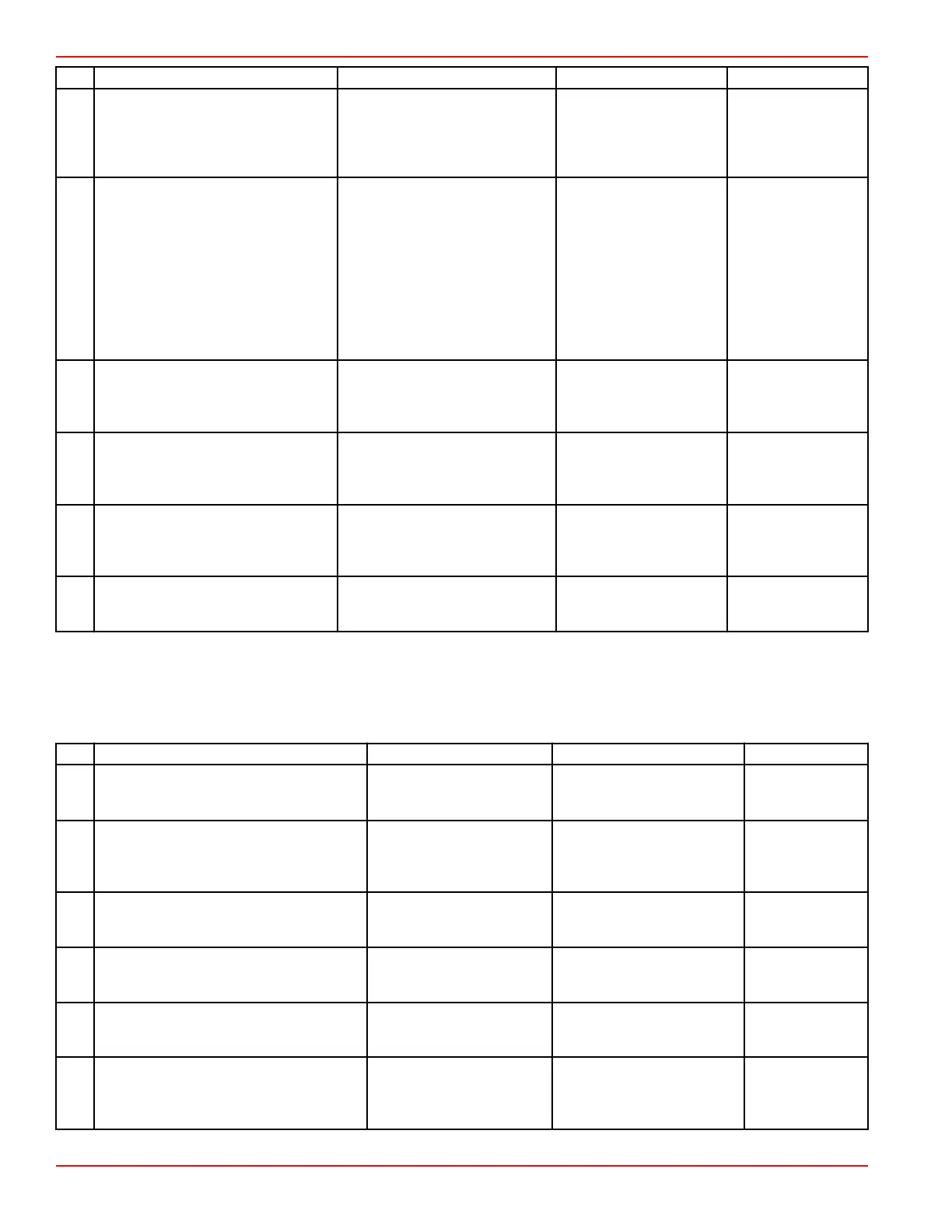

Step Diagnostic Process Details Yes No

8

Verify that at least 9.5 V are available

to the solenoid at terminal "S," during

cranking.

Is there adequate voltage to

engage the starter solenoid?

Refer to Section 4A ‑ Low

Voltage Tests .

Replace the starter

solenoid or the starter

motor assembly.

Go to step 9.

9

With the key in the start position,

check for battery voltage at terminal

86 of the starter relay socket.

Is the voltage within 1.0 V of

battery?

–

Test the relay (refer to

PCM 112–Section 3A ‑

Component testing).

• If the relay is bad,

replace it and retest

the system.

• If the relay is good,

there is an open

between the relay

and the solenoid.

There is a problem

in the circuit that

supplies voltage to

terminal 86 of the

starter relay.

10

Verify that at least 9.5 V are available

to the starter motor during cranking.

Is there adequate voltage to turn

the starter motor?

Refer to Section 4A ‑ Low

Voltage Tests .

Go to step 11.

Perform the Voltage

Drop Test in

Section 4A ‑

Starting System.

11

Remove the starter assembly from

the engine. Test it with a 12‑volt

source.

Does the starter operate correctly?

–

Inspect the flywheel ring

gear for damage. If it

appears okay, reinstall

the starter. Go to step 12.

The starter assembly

is bad.

12

Uncouple the engine from the

sterndrive.

Does the engine turn over with the

sterndrive disconnected?

–

The problem is in the

sterndrive. Refer to the

appropriate sterndrive

service manual.

Go to step 13.

13

Is the motor locked up?

Check for water in cylinders,

internal mechanical issues, and

corrosion.

Refer to Section 3 ‑

Engine Mechanical.

Contact Mercury

Product Service.

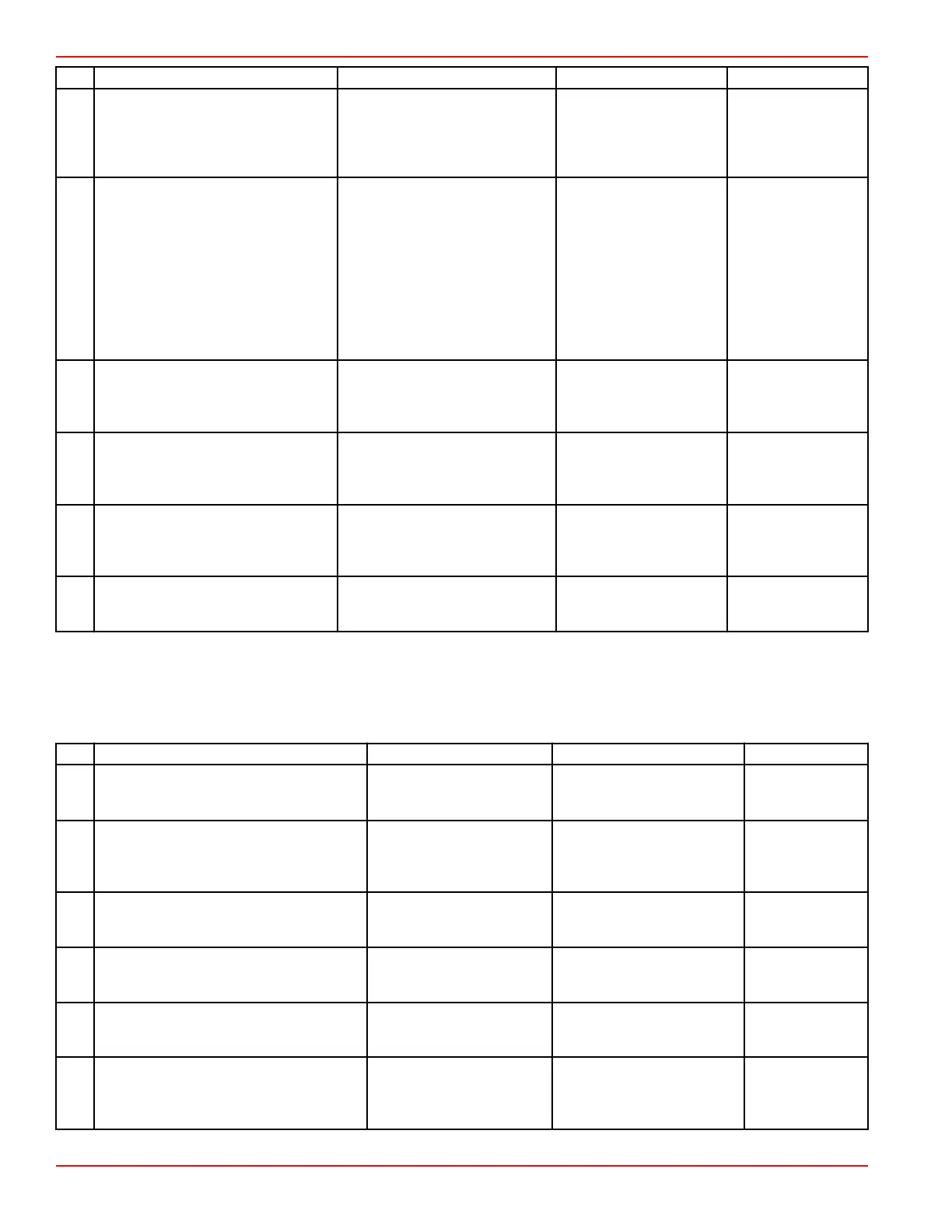

Chart R4: Engine Cranks Over but Will Not Start

This procedure is intended to diagnose a PCM 112 mechanical shift engine that rotates the crankshaft, but will not start when

the key switch is held in the start position. You are here because you answered no to step 4 of the diagnostic roadmap.

Step

Diagnostic Process Details Yes No

1

Did you complete the Visual/Physical

Check?

– Go to step 2.

Perform the

Visual/Physical

Check.

2

Use the CDS G3 service tool to check for

faults.

Are there any faults?

If a sensor has failed, it will

normally set a fault in the

PCM. For the CPS, see the

note, following.

Troubleshoot the faults.

Refer to the PCM 112

Service Manual.

Go to step 3.

3

Check for adequate spark at all of the

spark plugs.

Was adequate spark present?

– Go to step 4.

Go to Chart T4.

4

Connect a known good fuel source in

place of the boat's fuel tank.

Does the engine start?

–

The problem is with the boat

fuel supply.

Go to step 5.

5

Inspect the fuel filter.

Is the fuel filter obstructed?

–

Clean or replace the fuel

filter. Test the fuel for

contaminants.

Go to step 6.

6

Check the fuel pressure at the fuel rail.

Was the fuel pressure within

specification when the pump was

operating?

Refer to Section 5A ‑ Fuel

Pressure Gauge Setup

and Use.

Go to step 7.

Go to Chart T3.

Troubleshooting

Page 1D-8 © 2016 Mercury Marine 90-8M0099748 eng DECEMBER 2015

Loading...

Loading...