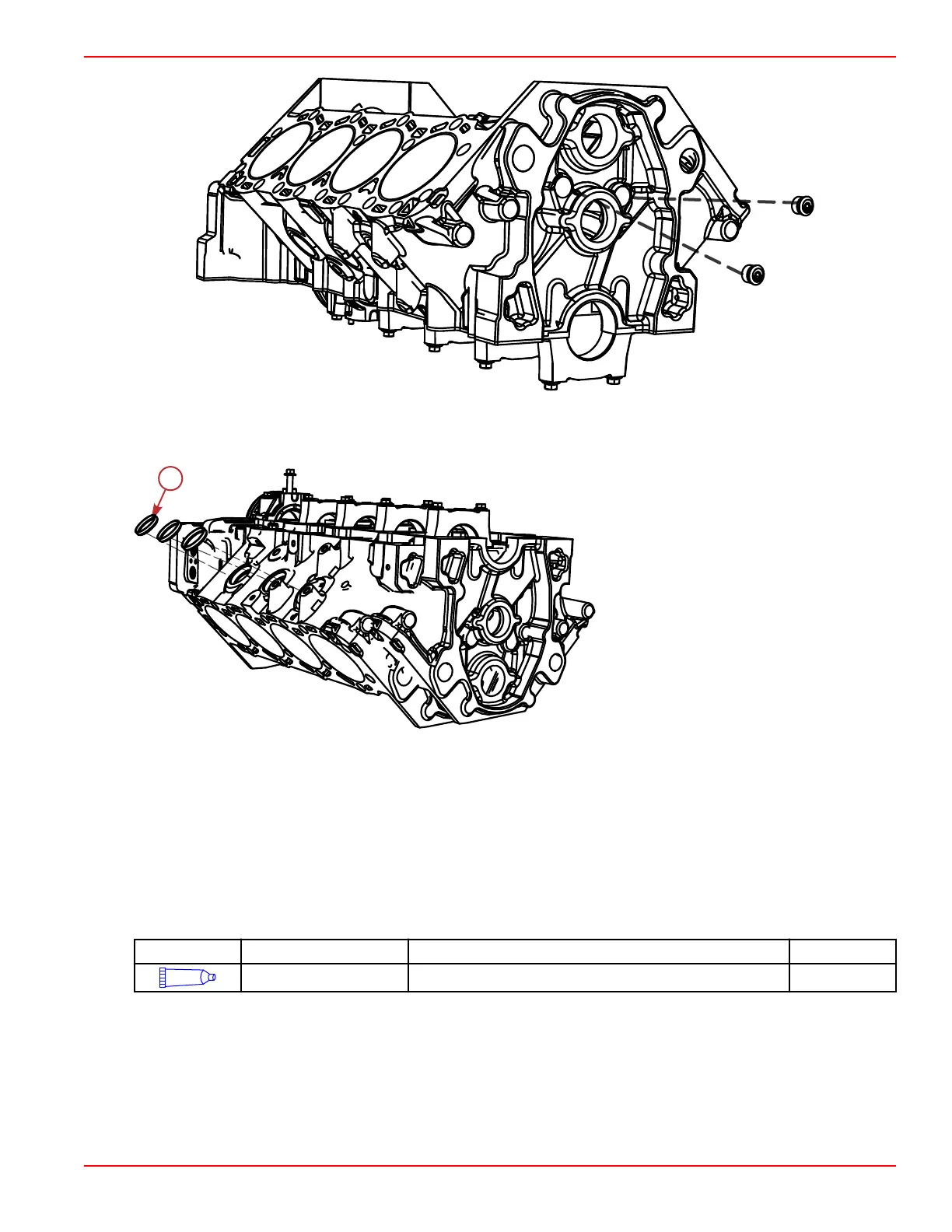

Front oil gallery plugs

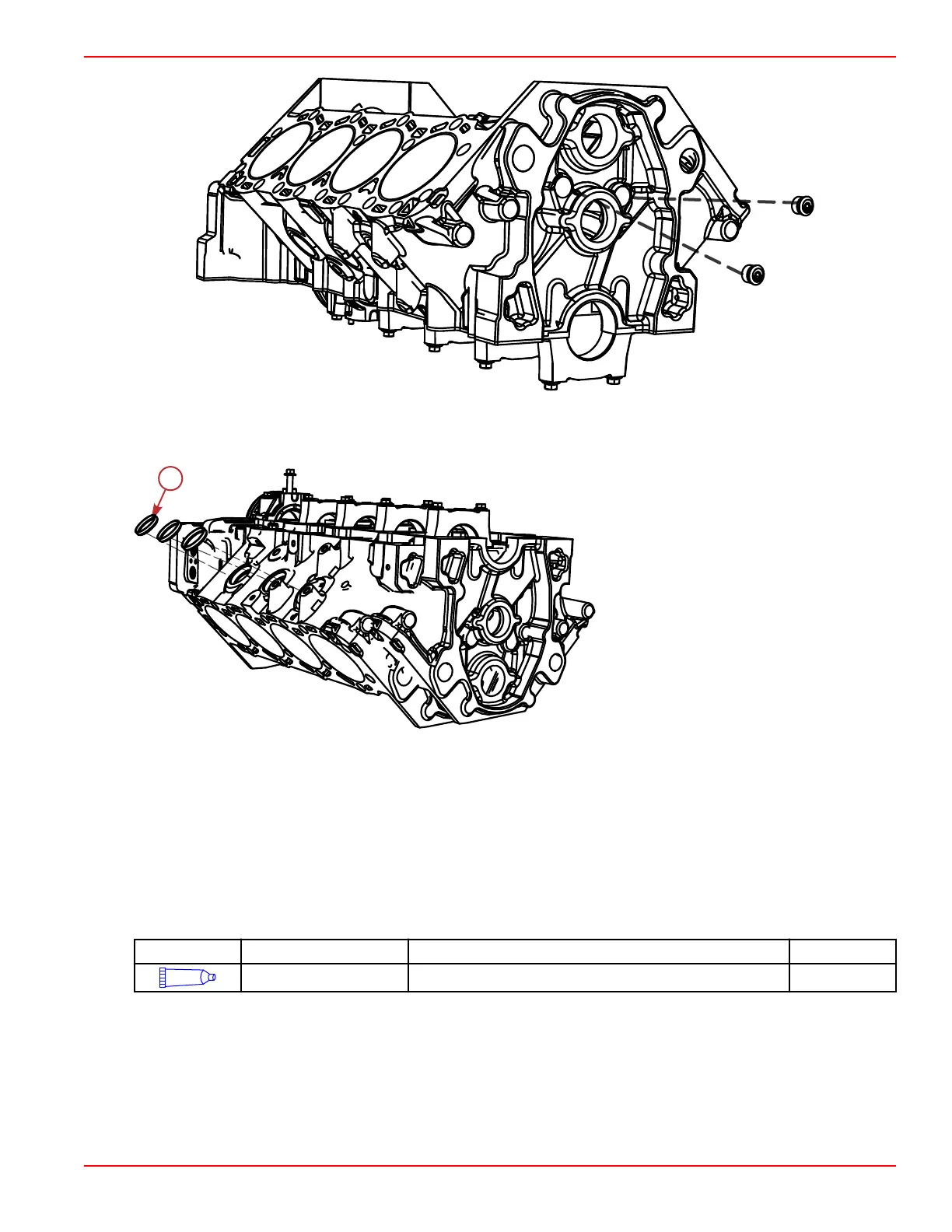

4. Remove and discard the engine block core hole expansion plugs on both sides of the block.

a - Freeze plug (6 used)

5. Clean all sealing surfaces.

6. Remove all gasket and sealant residue.

7. Clean the engine block with cleaning solvent.

8. Flush the engine block with clean water or steam clean.

9. Clean the cylinder bores.

10. Clean the oil galleries and oil passages.

11. Clean scale and deposits from the coolant passages.

12. Clean the engine block cylinder head bolt holes and dry with compressed air.

13. After cleaning the engine block, spray or wipe the cylinder bores and other machined surfaces with clean engine oil.

Tube Ref No.

Description Where Used Part No.

80

SAE Engine Oil 30W Cylinder bores and other machined surfaces Obtain Locally

Camshaft Bearings

1. Inspect camshaft bearings for excessive wear or scoring. If any camshaft bearing is excessively worn or scored, replace all

the camshaft bearings.

2. Inspect the camshaft bearings for correct fit into the engine block camshaft bearing bores. The camshaft bearings have an

interference fit to the engine block camshaft bearing bores and must not be loose in the bores.

Camshaft Bearings Removal

1. The camshaft bearing service kit is required to remove and install the camshaft bearings.

Engine Disassembly

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 3A-43

Loading...

Loading...