SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2002 SF-1803 Page 2-17 Printed in U.S.A.

Code C645. (Continued)

(Error Type: RESTART )

(Continued)

C645: VENT MODE

PRESSURE HIGH

ITEMS NOT STERILE

PUSH STOP TO RESTART

Absolute pressure inside

chamber is greater than

0.7 PSIg (5 kPa) for longer

than 5 minutes (i.e., Vent

mode not complete).

Pressure Transducer or

Main P.C. Board Malfunc-

tioning.

Check for 5.0 VDC

between TP2 & TP4 &

pins of Pressure Trans-

ducer. (Refer to Sche-

matic in Section 5).

Voltage should be apprx.

4.5 VDC at all times with

unit plugged in. Also, run

Service Diagnostics.

If voltage is not present or Ser-

vice Diagnostics reveals a

problem replace P.C. Board

(Refer to para 4.13).

Code

C647.

(Error Type: RESTART )

C647: DRY MODE

PRESSURE HIGH

PUSH STOP TO RESTART

Gauge pressure inside

chamber is equal to or

greater than 2.18 PSIg

(15 kPa) during DRY mode

or 0.7 PSIg (5 kPa) during

DOOR mode.

Door did not fully open

even though latch

released allowing cham-

ber to retain a slight

pressure.

Door Gasket may have

stuck due to abnormally

high temperatures at

Start-up (230° F [110° C]

or above) due to running

back-to-back cycles over

a period of time.

Run Service Diagnostics

to check component

operation. Check amount

of cycles (back-to-back)

Operator ran before

problem occurred. Check

condition of door gasket.

If door gasket is worn or dirty

clean or replace gasket (Refer

to para 4.8).

Inform Operator that problem

could occur when back-to-

back cycles have been ran

and Start-up temperature is

230° F [110° C] or above.

Filter screen in chamber

restricted.

Remove filter screen and

check condition.

Clean or replace filter screen.

Vent Valve malfunction-

ing or related lines or fit-

tings restricted.

Run Service Diagnostics

and check Vent Valve

operation and check for

debris in Valve and

related lines and fittings.

Clean or replace Vent Valve,

related lines and fittings (Refer

to para 4.18).

Pressure Transducer or

Main P.C. Board Mal-

functioning.

Check for 5.0 VDC

between TP2 & TP4 &

pins of Pressure Trans-

ducer. (Refer to Sche-

matic in Section 5).

Voltage should be apprx.

4.5 VDC at all times with

unit plugged in. Also, run

Service Diagnostics.

If voltage is not present or Ser-

vice Diagnostics reveals a

problem replace P.C. Board

(Refer to para 4.13).

Code

C660.

(Error Type: FATAL )

Note: When a Code ends in

“0” it means unit had a sup-

ply power interruption.

The operator could have

unplugged the unit when a

previous Code was dis-

played.

Always go to Service Diag-

nostics and check previous 5

codes that are displayed.

C660: POWER UP MODE

PRESSURE HARDWARE

UNPLUG / RE-PLUG UNIT

Pressure A / D converter

reports an average value

outside the limits for nor-

mal operation during

POWER UP mode.

May be due to a malfunc-

tion that occurred previ-

ously to Code displayed.

Go to Service Diagnos-

tics and check previous 5

displayed codes.

Refer to Code Numbers in

Troubleshooting Guide to

determine correction.

Pressure Transducer or

Main P.C. Board Mal-

functioning.

Check for 5.0 VDC

between TP2 & TP4 &

pins of Pressure Trans-

ducer. (Refer to Sche-

matic in Section 5).

Voltage should be apprx.

4.5 VDC at all times with

unit plugged in. Also, run

Service Diagnostics.

If voltage is not present or Ser-

vice Diagnostics reveals a

problem replace P.C. Board

(Refer to para 4.13).

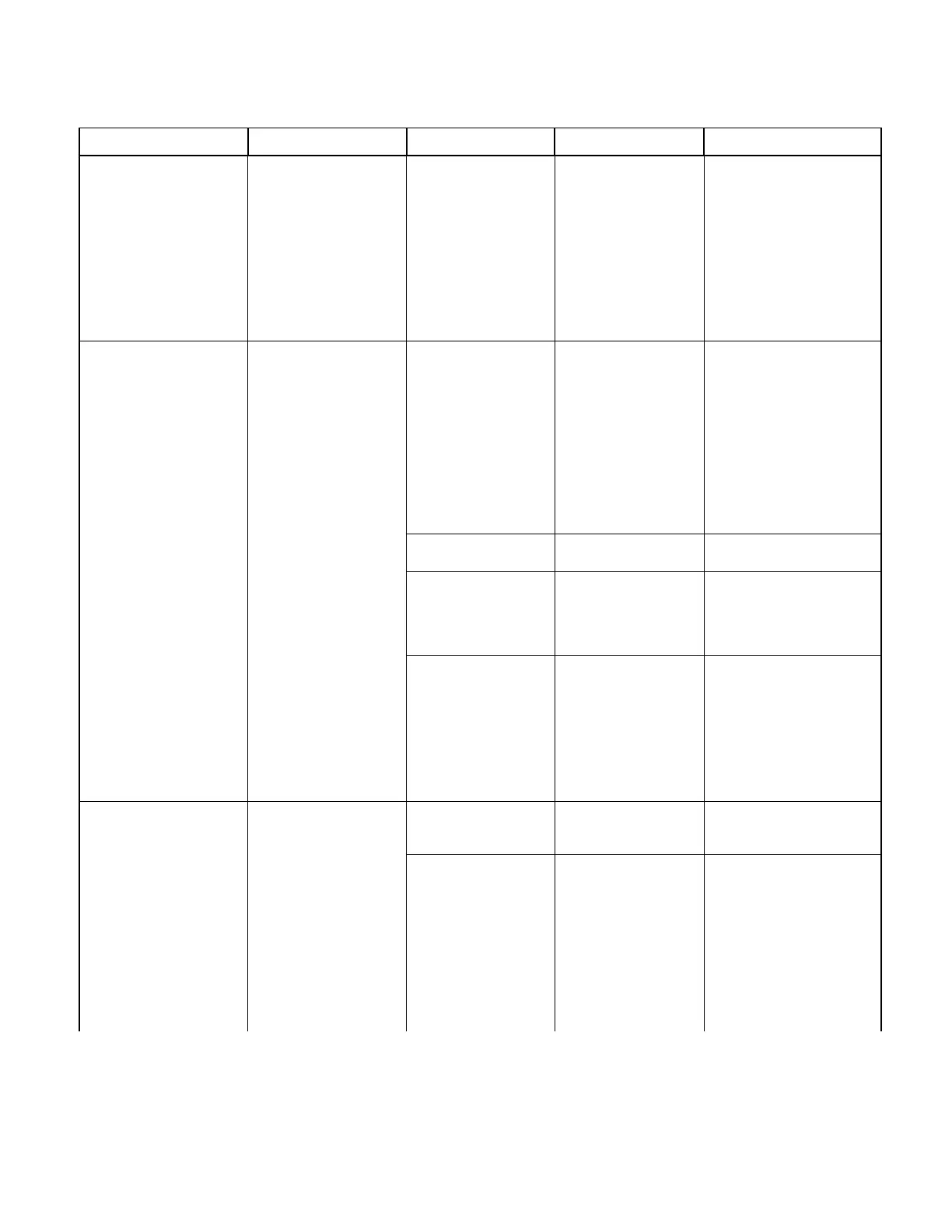

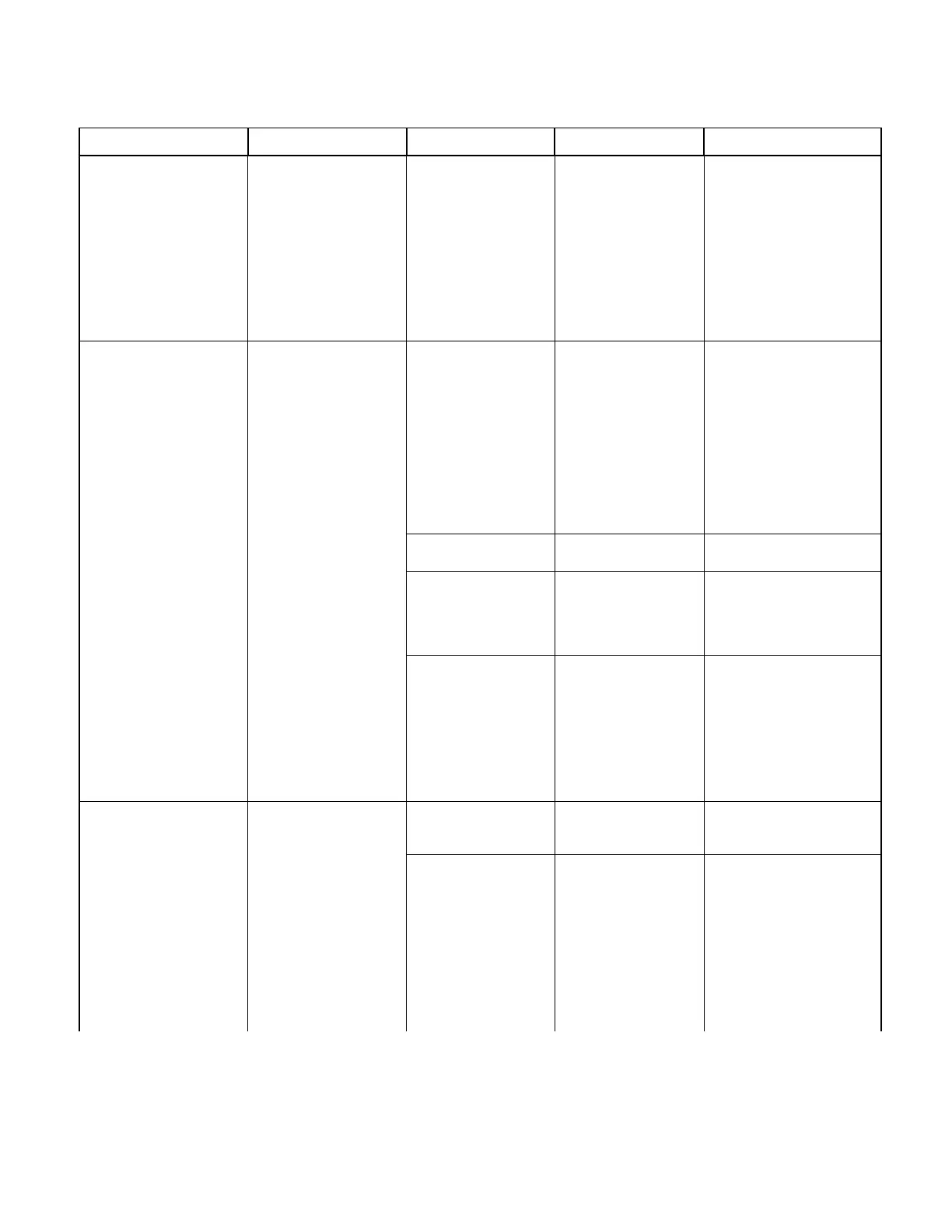

Table 2-3. Troubleshooting Guide

Problem Display / Symptom Probable Cause Check Correction

Return To Table of Contents

Loading...

Loading...