OM-278174 Page 70

10-15. Troubleshooting – Distortion

Distortion - contraction of weld metal during welding that forces base metal to move.

Illustration: Base metal moves in the direction of the weld bead.

Possible Causes Corrective Actions

Excessive heat input. Use restraint (clamp) to hold base metal in position.

Make tack welds along joint before starting welding operation.

Select lower voltage range and/or reduce wire feed speed.

Increase travel speed.

Weld in small segments and allow cooling between welds.

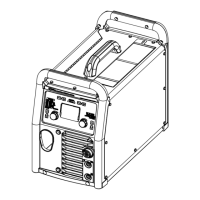

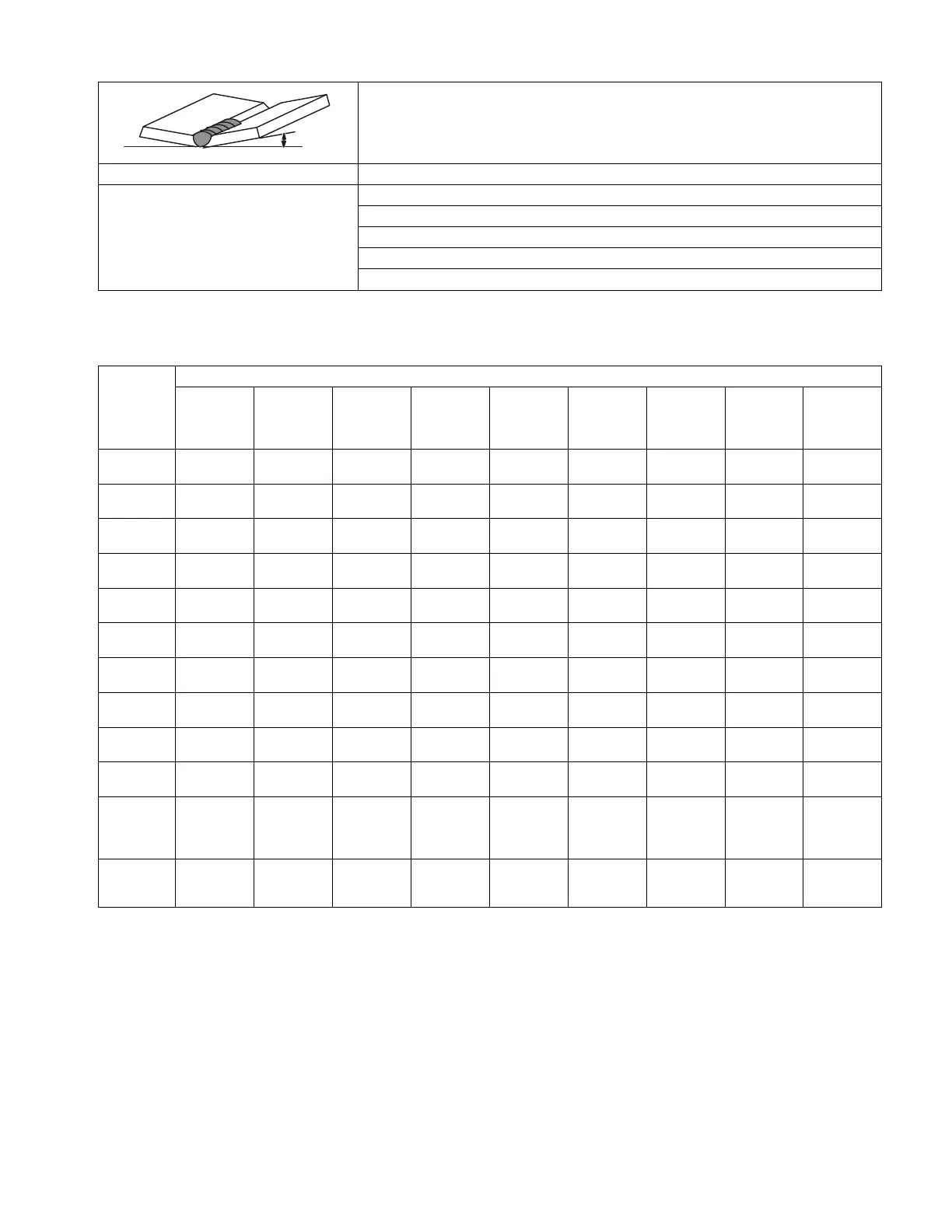

10-16. Common MIG Shielding Gases

This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been devel-

oped over the years. The most commonly used shielding gases are listed in the following table.

Gas

Application

Spray Arc

Steel

Short Cir-

cuiting

Steel

GMAW-P

Steel

Spray Arc

Stainless

Steel

Short Cir-

cuiting

Stainless

Steel

GMAW-P

Stainless

Steel

Spray Arc

Aluminum

Short Cir-

cuiting

Aluminum

GMAW-P

Aluminum

Argon

All

Positions

All

Positions

All

Positions

All

Positions

Argon + 1%

O

2

Flat & Hori-

zontal Fillet

All

Positions

Flat & Hori-

zontal Fillet

Argon + 2%

O

2

Flat & Hori-

zontal Fillet

All

Positions

Flat & Hori-

zontal Fillet

Argon + 5%

CO

2

Flat & Hori-

zontal Fillet

All

Positions

Argon +

10% CO

2

Flat & Hori-

zontal Fillet

All

Positions

All

Positions

Argon +

25% CO

2

All

Positions

Argon +

50% CO

2

All

Positions

CO

2

All

Positions

Helium

All

Positions*

Argon +

Helium

All

Positions*

90% HE +

7-1/2% AR

+ 2-1/2%

CO

2

All

Positions

65% AR +

33% HE +

2% CO

2

All

Positions

* Heavy Thicknesses

Loading...

Loading...