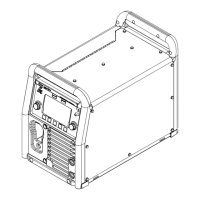

OM-278174 Page 71

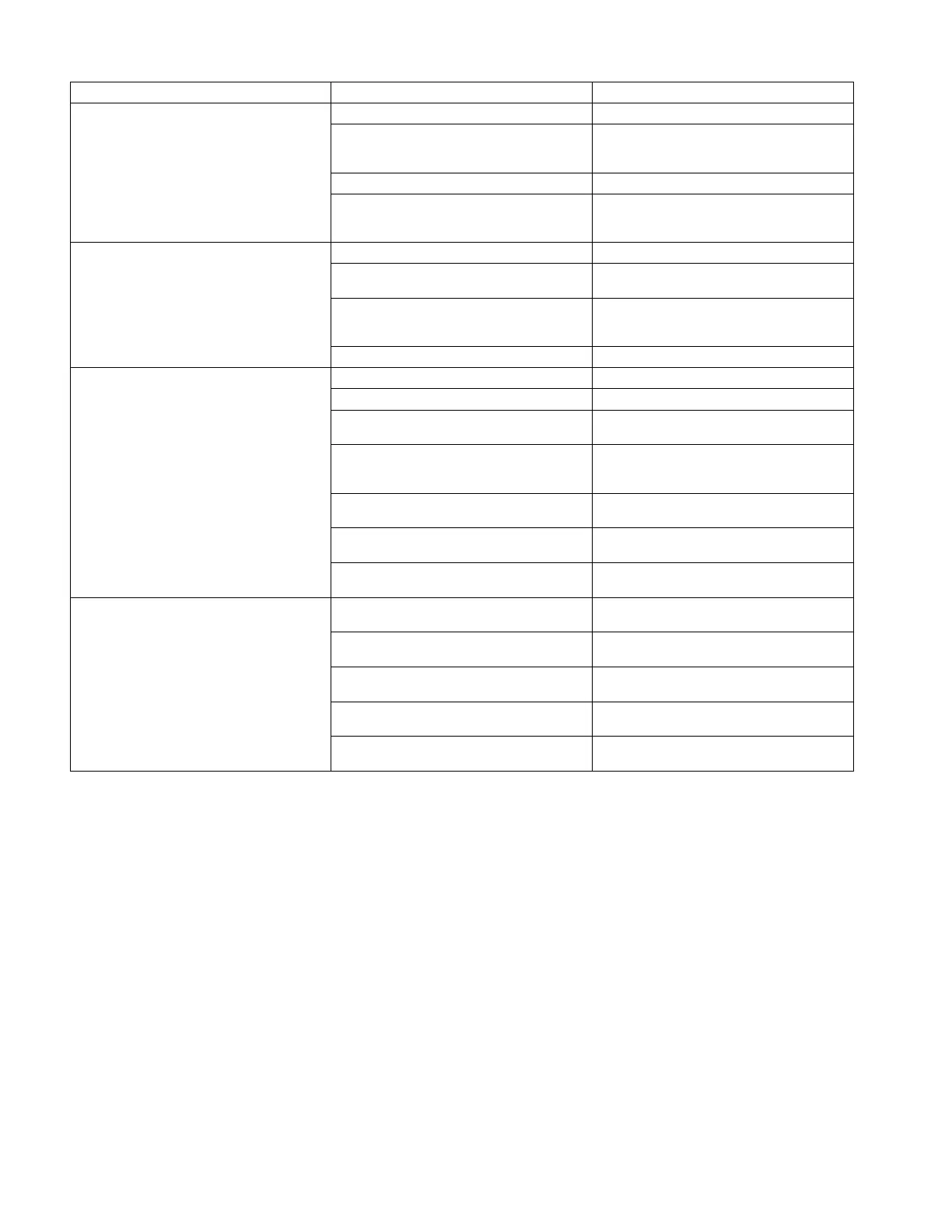

10-17. Troubleshooting Guide For Semiautomatic Welding Equipment

Problem Probable Cause Remedy

Wire feed motor operates, but wire does not

feed.

Too little pressure on wire feed rolls. Increase pressure setting on wire feed rolls.

Incorrect wire feed rolls. Check size stamped on wire feed rolls, re-

place to match wire size and type if

necessary.

Wire spool brake pressure too high. Decrease brake pressure on wire spool.

Restriction in the gun and/or assembly. Check and replace cable, gun, and contact

tip if damaged. Check size of contact tip and

cable liner, replace if necessary.

Wire curling up in front of the wire feed rolls

(bird nesting).

Too much pressure on wire feed rolls. Decrease pressure setting on wire feed rolls.

Incorrect cable liner or gun contact tip size. Check size of contact tip and check cable lin-

er length and diameter, replace if necessary.

Gun end not inserted into drive housing

properly.

Loosen gun securing bolt in drive housing

and push gun end into housing just enough

so it does not touch wire feed rolls.

Dirty or damaged (kinked) liner. Replace liner.

Wire feeds, but no gas flows (GMAW). Gas cylinder empty. Replace empty gas cylinder.

Gas nozzle plugged. Clean or replace gas nozzle.

Gas cylinder valve not open or flowmeter not

adjusted.

Open gas valve at cylinder and adjust flow

rate.

Restriction in gas line. Check gas hose between flowmeter and wire

feeder, and gas hose in gun and cable

assembly.

Loose or broken wires to gas solenoid. Have Factory Authorized Service Agent re-

pair wiring.

Gas solenoid valve not operating. Have Factory Authorized Service Agent re-

place gas solenoid valve.

Incorrect primary voltage connected to weld-

ing power source.

Check primary voltage and relink welding

power source for correct voltage.

Welding arc not stable. Wire slipping in drive rolls. Adjust pressure setting on wire feed rolls. Re-

place worn drive rolls if necessary.

Wrong size gun liner or contact tip. Match liner and contact tip to wire size and

type.

Incorrect voltage setting for selected wire

feed speed on welding power source.

Readjust welding parameters.

Loose connections at the gun weld cable or

work cable.

Check and tighten all connections.

Gun in poor shape or loose connection inside

gun.

Repair or replace gun as necessary.

Loading...

Loading...