OM-253 906 Page 35

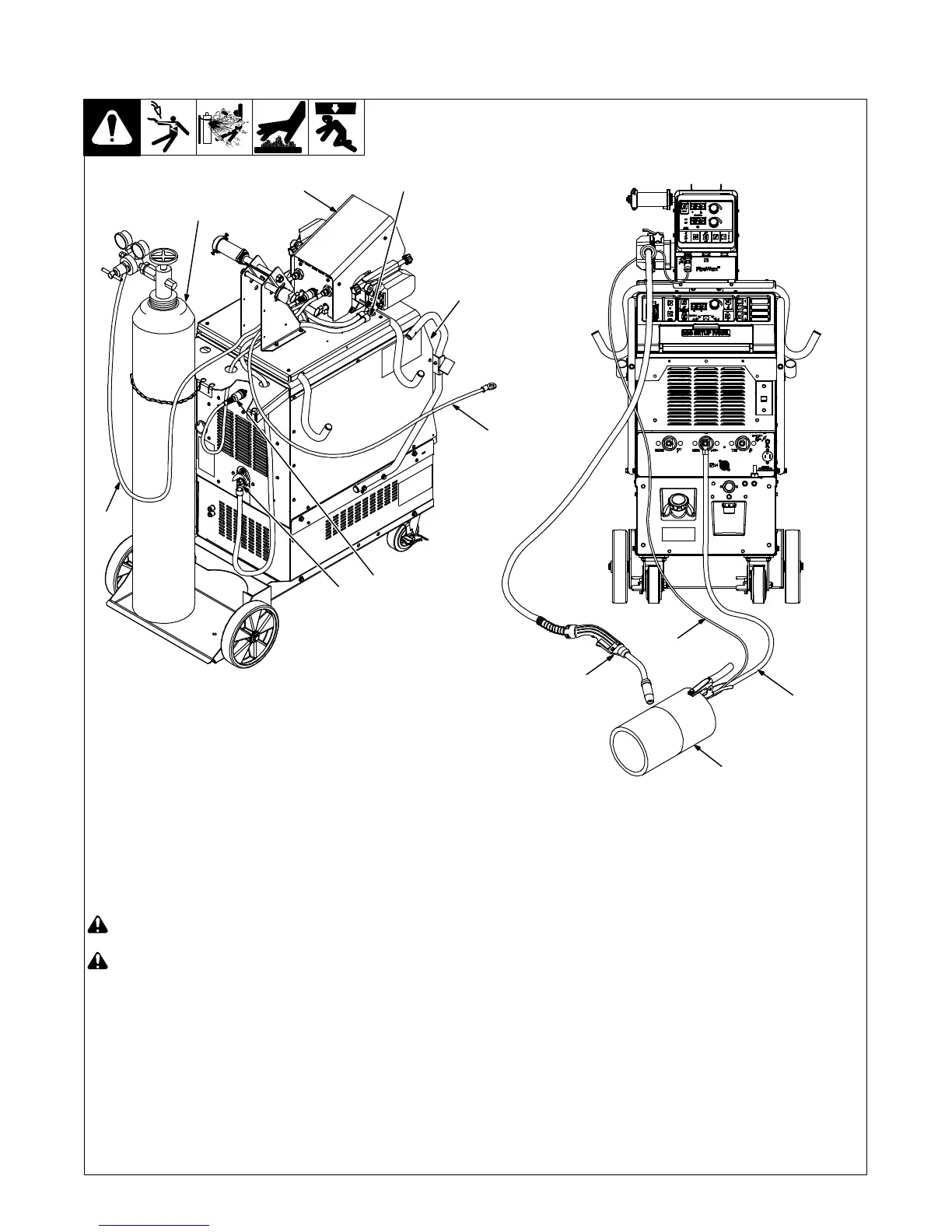

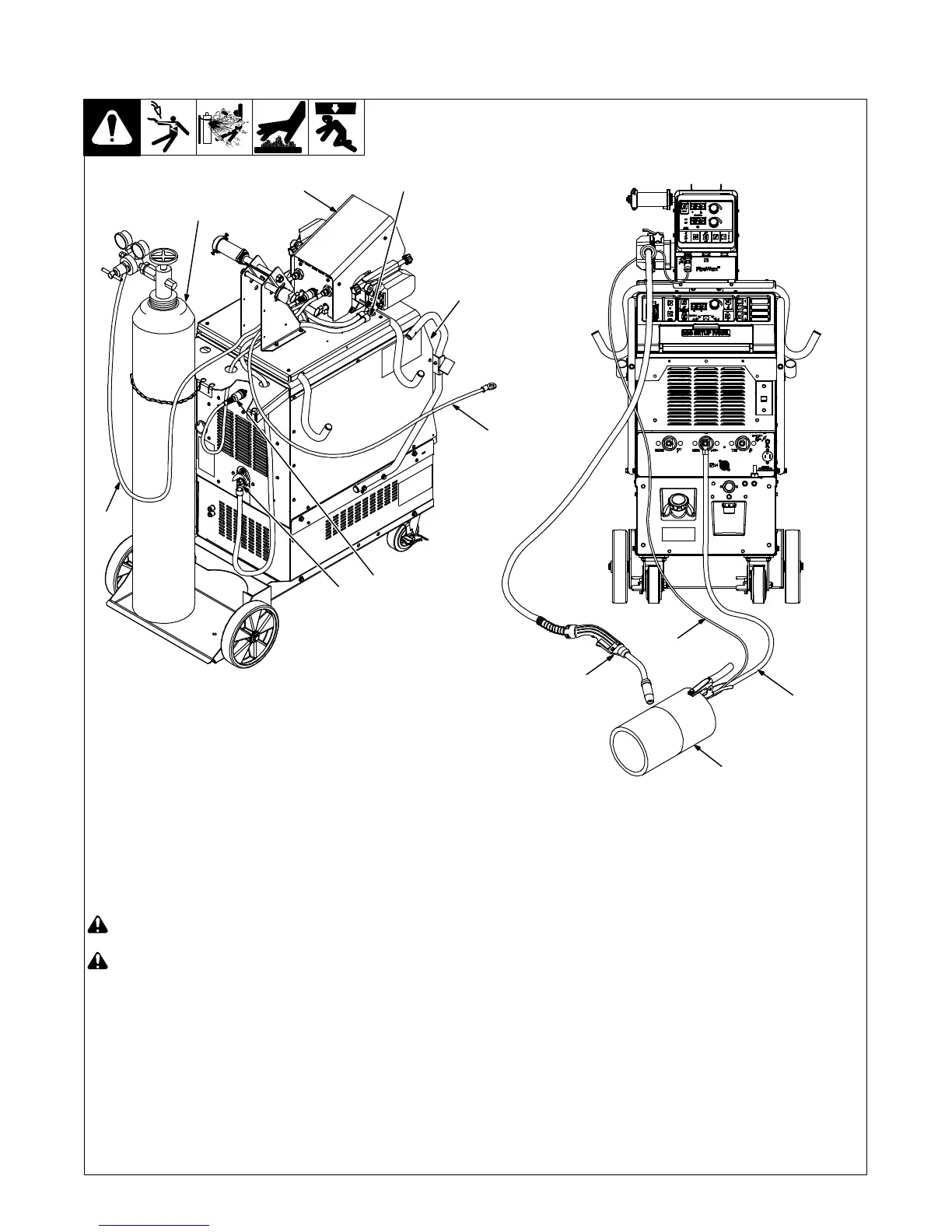

5-18. Typical Connection Diagram For MIG (GMAW) Equipment With Feeder

On Power Source

! Do not put feeder where welding

wire hits cylinder.

! Do not move or operate equipment

when it could tip.

1 Welding Power Source

2 Wire Feeder

3 MIG Connection

4 Positive (+) Weld Cable

5 Feeder Control Cable Connection

6 Gas Hose

7 Gas Cylinder

Connect 14-pin plug to rear of power

source, and connect 14-socket plug to rear

of wire feeder. Connect one end of weld

cable to weld terminal on rear of power

source. Connect remaining end of weld

cable to wire feeder drive housing. Connect

one end of gas hose to regulator/flowmeter

on gas cylinder and connect remaining end

of gas hose to gas solenoid connector on

rear of feeder or Y-hose for dual wire feeder.

8 Work (−) Weld Cable

. Attach volt sense lead to work clamp

and attach work clamp as close to arc

as possible.

9 Volt Sense Cable

10 Workpiece

11 Welding Gun

254 079-A

1

6

4

7

2

5

3

9

8

11

9

10

Loading...

Loading...