OM-253 906 Page 30

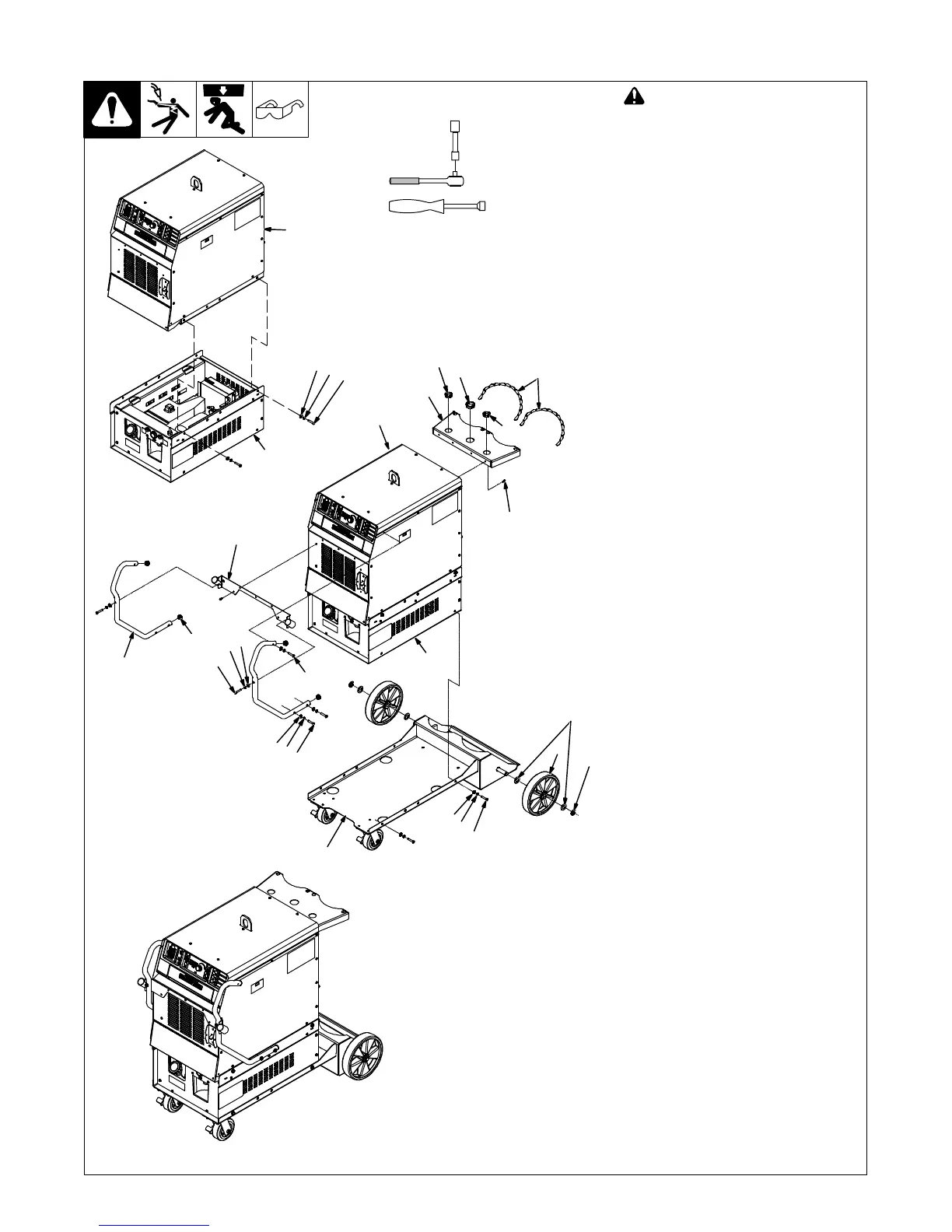

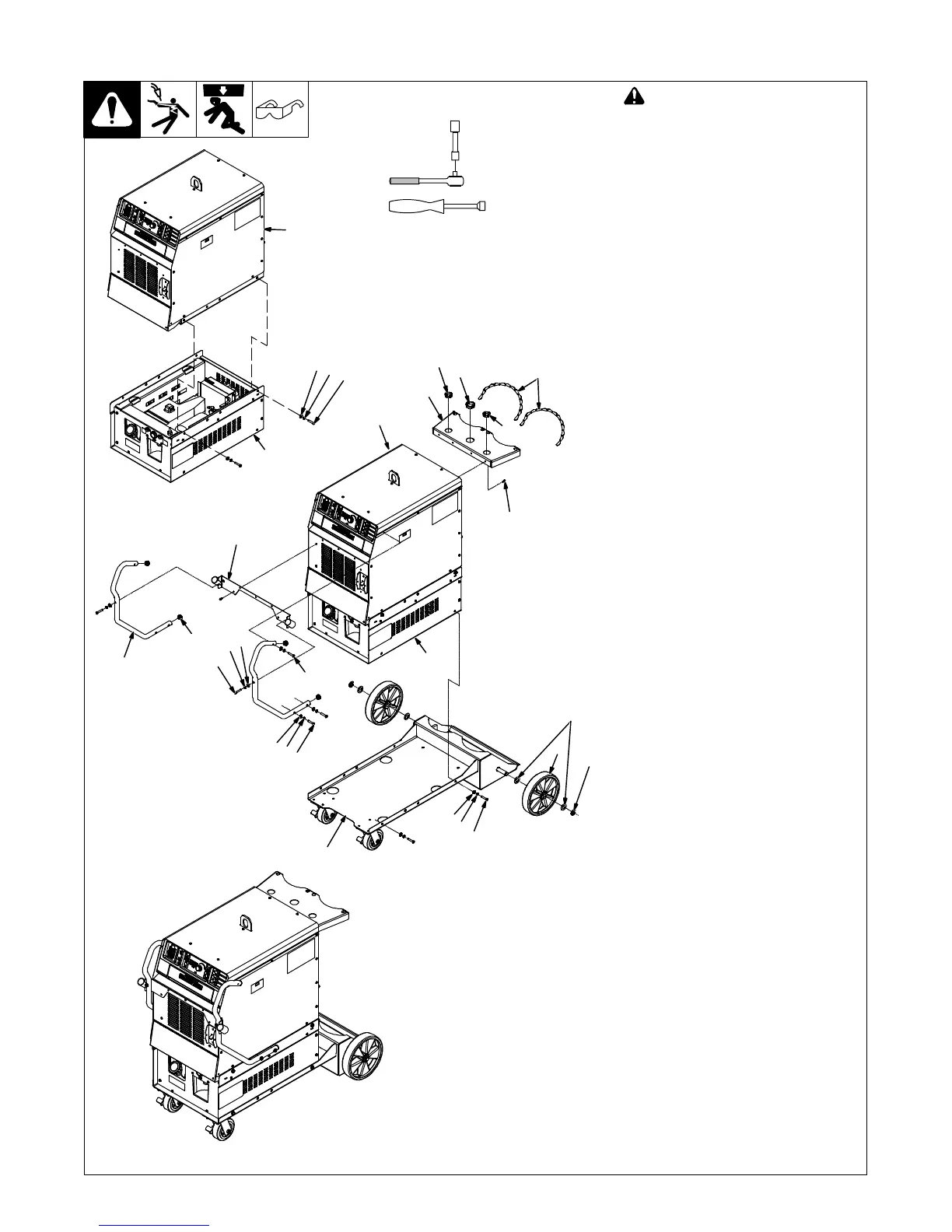

5-12. Installing Optional Handles, Running Gear And Cooler

805 302-A / 805 292-A

! Turn Off welding power source,

disconnect input power.

1 Running Gear 234 359

2 Cooler

3 Wheel 163 463 (2)

4 Flat Washer 602 250 (4)

5 Retaining Ring 121 614 (2)

Install wheels on cylinder tray as shown.

Set cooler on running gear.

. If not installing a cooler, set power

source on running gear.

6 Flat Washer 602 240 (4)

7 Lock Washer 602 211 (4)

8 Screw 601 944 (4)

Secure cooler to running gear using

supplied flat washers, lock washers and

screws.

9 Power Source

Set power source on cooler.

Secure power source to cooler using

same hardware that was used to secure

cooler to running gear.

10 Cylinder Support Bracket

11 Bushing 170 647 (2)

12 Bushing 004 214 (1)

13 Screw 128 237 (4)

14 Chain 188 441 (2)

Install cylinder support bracket to rear of

power source and secure with supplied

screws. Install bushings and chains.

15 Handle Bracket

16 Handle (2)

17 Tube Cap (4)

Install tube caps into ends of handles.

Remove 5 screws above louvered panel

on front of power source.

Attach handle bracket to front of power

source using the 5 screws previously

removed.

Remove 2 screws on the side of the cover

on front of power source.

18 Screw 234 483 (2)

Start supplied upper handle mounting

screws into handles by hand on each side

of power source.

19 Screw 604 535 (2)

20 Lock Washer 602 211 (2)

21 Flat Washer 602 240 (2)

Start supplied screws, lock washers and

flat washers into handle bracket by hand

on each side of power source.

22 Screw 604 535 (4)

23 Lock Washer 602 211 (4)

24 Flat Washer 602 240 (4)

Start supplied lower handle mounting

screws, lock washers and flat washers

into handles by hand on each side of

power source.

Tighten all handle hardware.

Tools Needed:

1/2 in.

5/16 in.

2

6

7

8

9

1

2

3

4

15

16

5

6

7

8

13

18

19

20

21

22

23

24

17

10

9

11

12

11

14

Loading...

Loading...