OM-253 906 Page 40

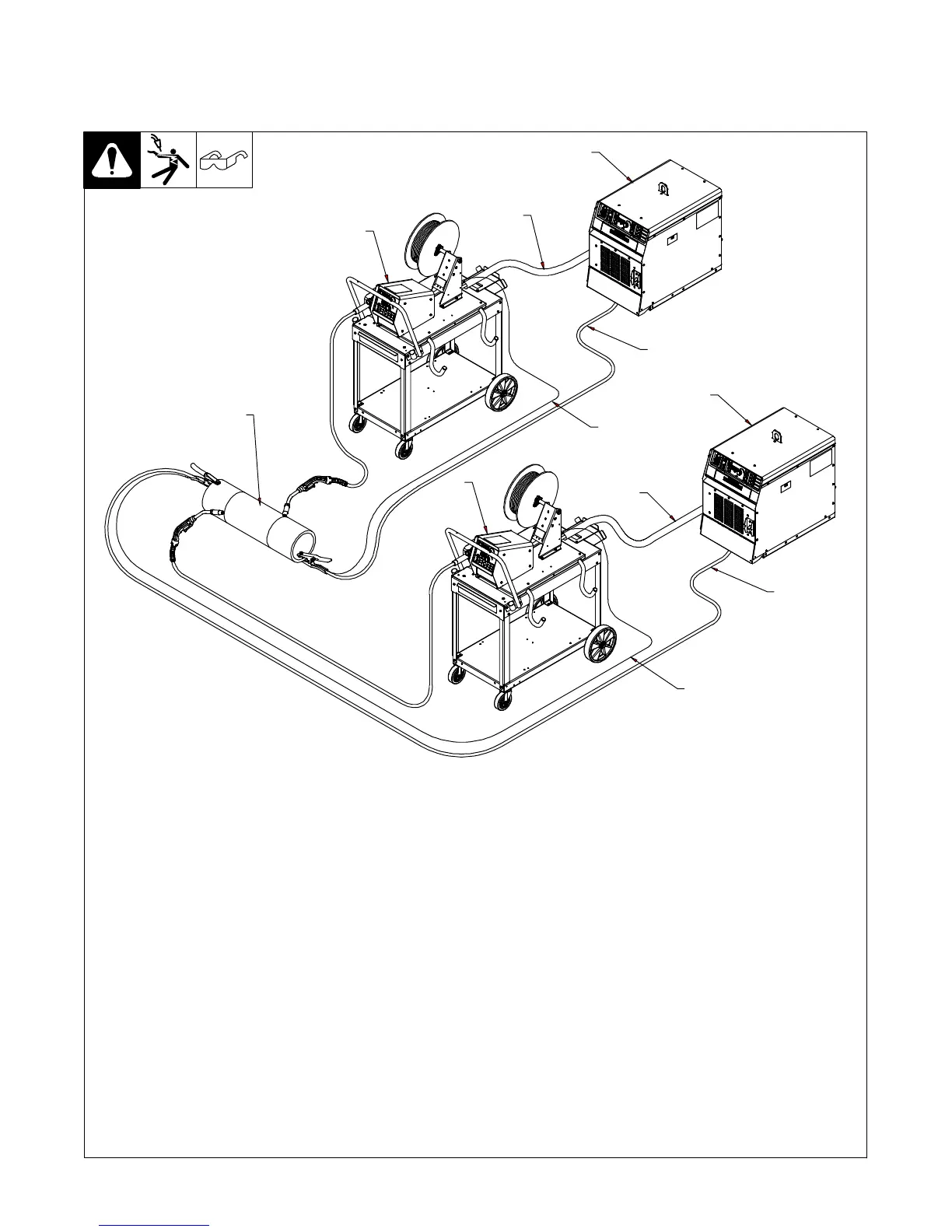

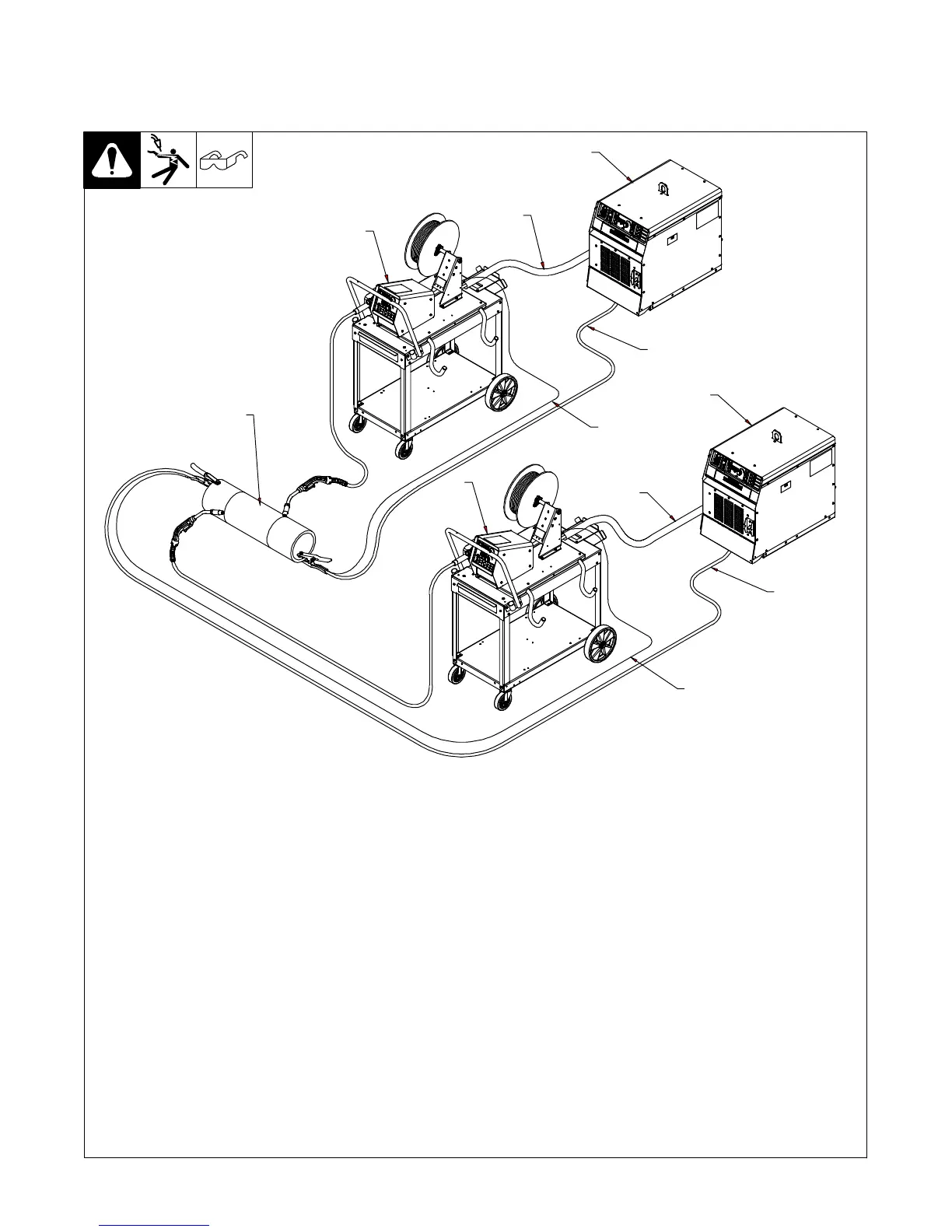

5-23. Voltage Sensing Lead And Work Cable Connections For Multiple Welding Arcs

A. Ideal Setup

805 289-B

1 Welding Power Source

2 Composite Cable

3 Work Cable

4 Volt Sense Lead

The volt sense lead must be used to

provide an accurate voltage feedback

signal to the welding system. Use of this

lead is critical for stable welding

performance.

5 Wire Feeder

6 Workpiece

This arrangement is an ideal setup for

supporting separate voltage feedback to

the welding power sources. The most

accurate voltage sensing may not be

achieved due to voltage drops in the

workpiece. This may require

compensation in the welding parameters.

1

2

3

4

5

6

1

2

3

4

5

Loading...

Loading...