Pellerin Milnor Corporation 29

Condition of Grooves on Pulleys

BNUUUM02.C03 0000274611 A.4 A.2 2/4/20 8:08 AM Released

Replace a pulley if:

• the grooves have burrs, cracks, or worn areas that can cause damage to the belts.

• the belts touch the bottom of the groove at any point (Figure 8 ).

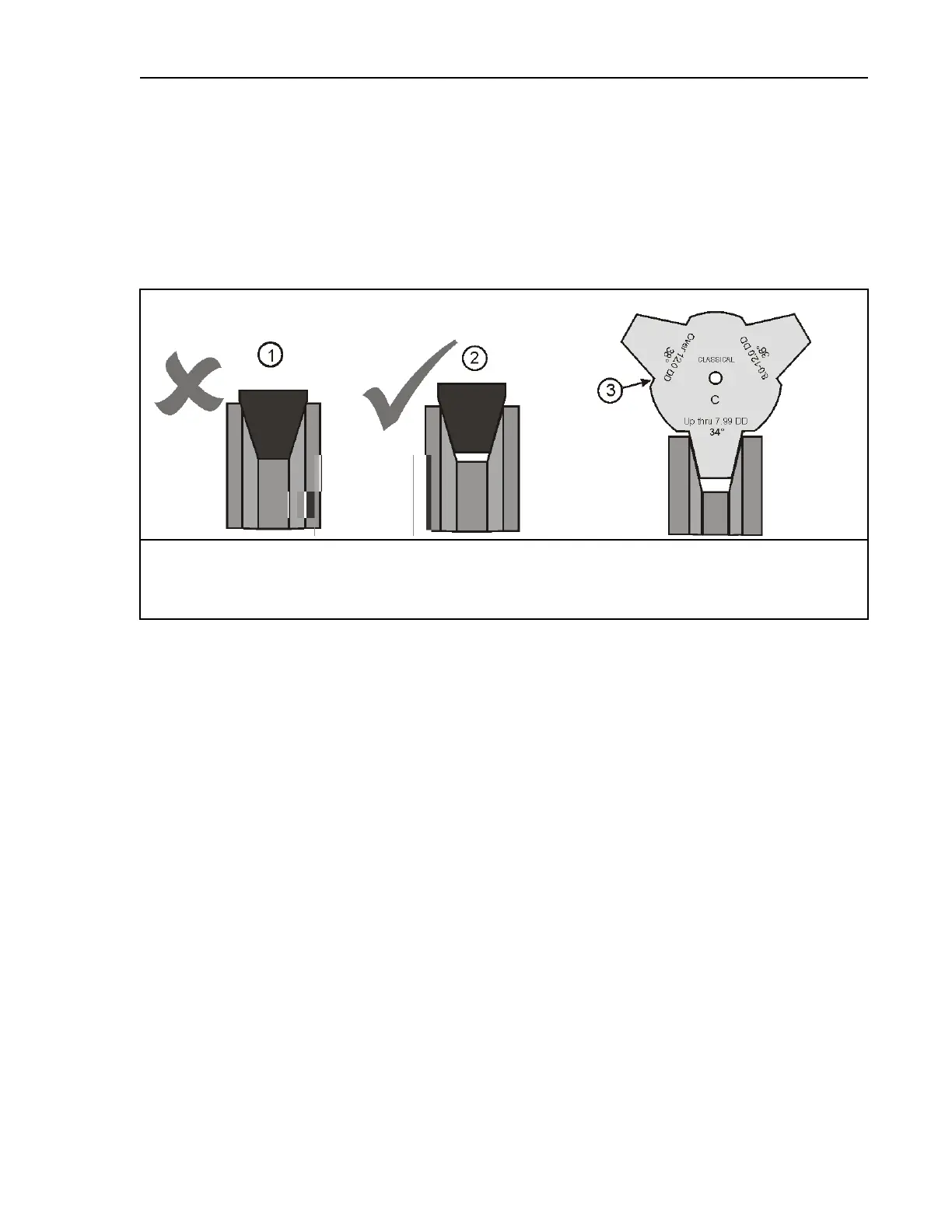

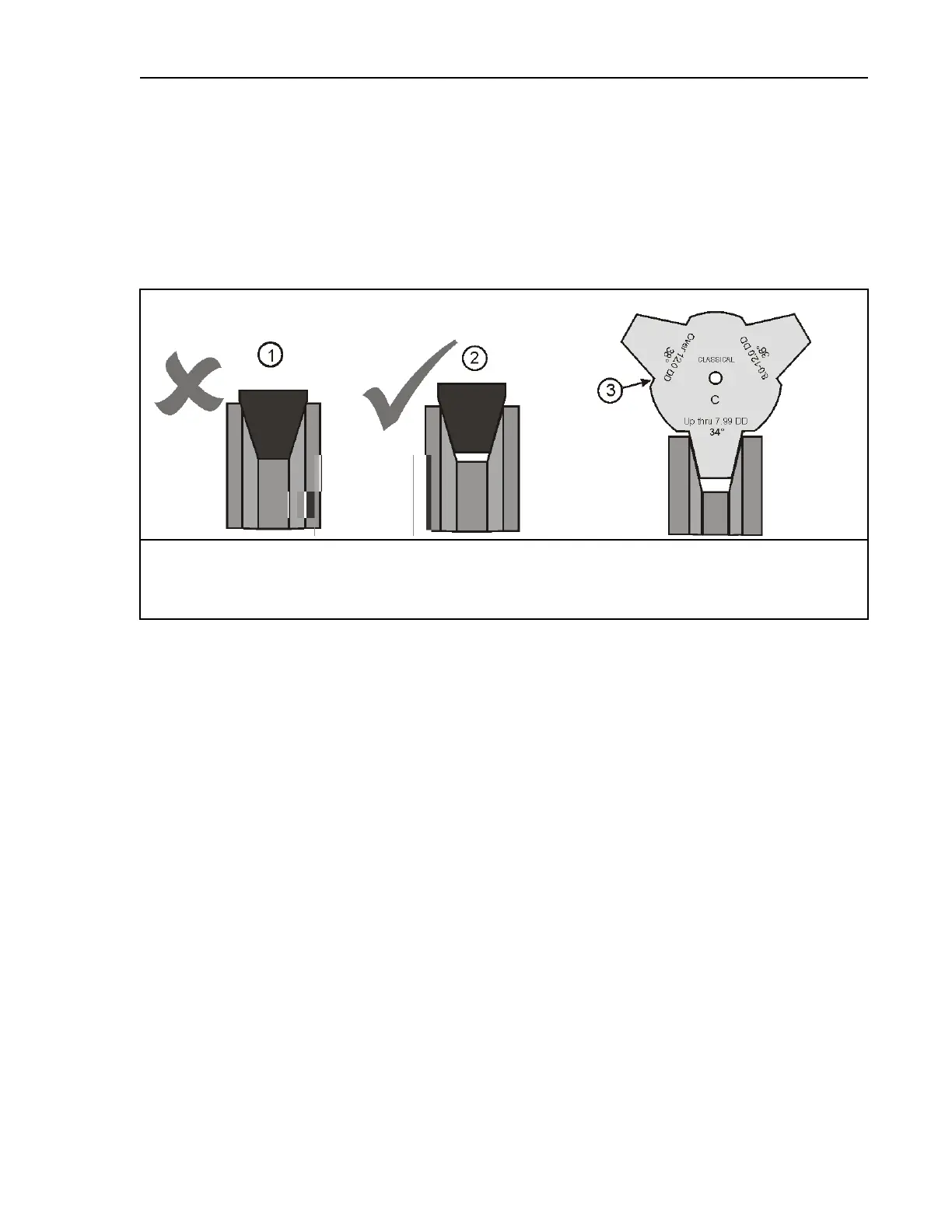

Figure 8. Pulley Groove Condition

Views of Incorrect and Correct Condition

Legend

1. Incorrect: Too much pulley wear. The belt touches the bottom of the groove.

2. Correct: The belt does not touch the bottom of the groove.

3. Use a sheave (pulley) gage to see if grooves are worn.

Pulley and Shaft Position

BNUUUM02.C04 0000274609 A.4 A.2 2/4/20 8:08 AM Released

Align To adjust parts until they are in a correct position to other parts.

• Always align components when you replace a motor, bearing housing, pulley, or belt.

• The belts must not twist or make unusual noises or show vibration.

Drive Assemblies

Loading...

Loading...