Pellerin Milnor Corporation 39

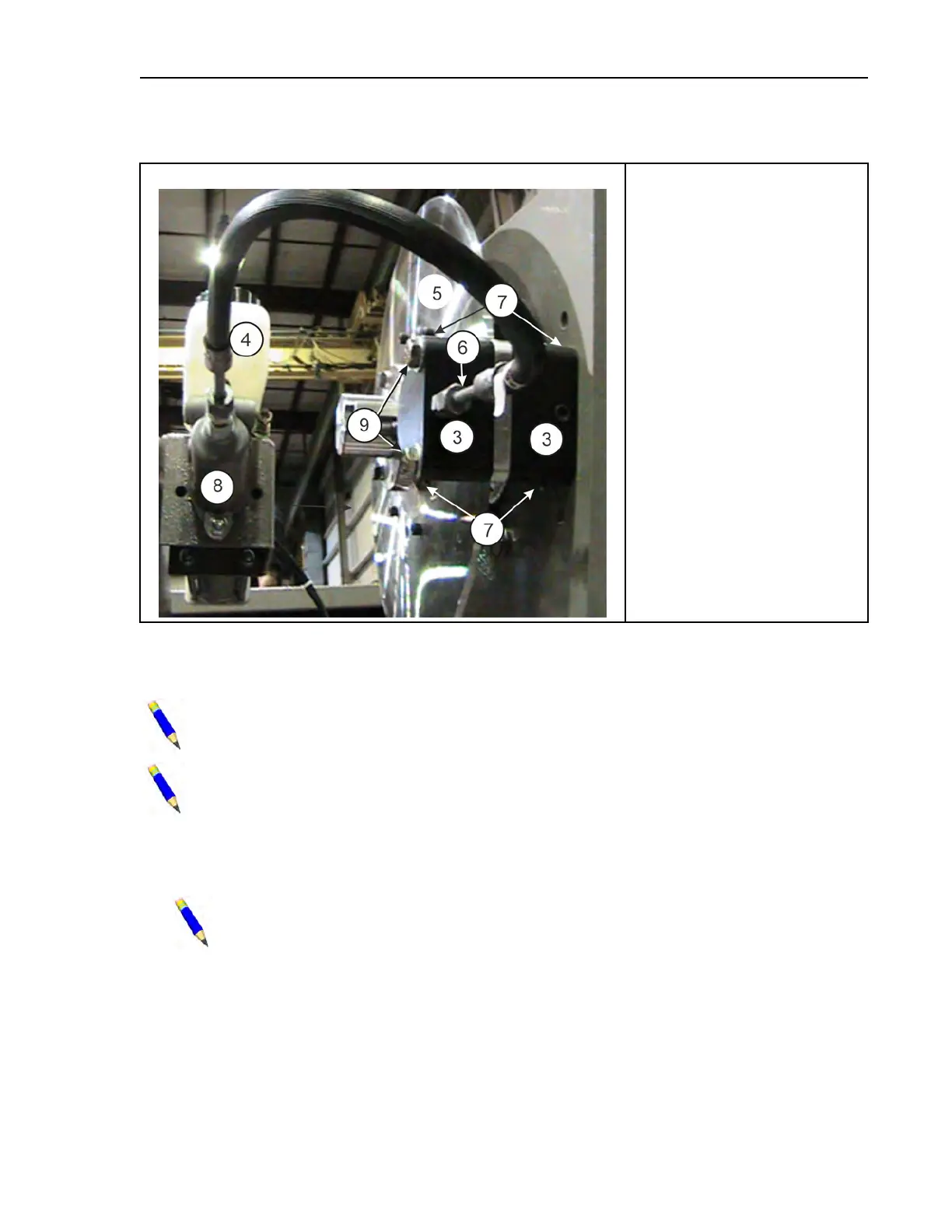

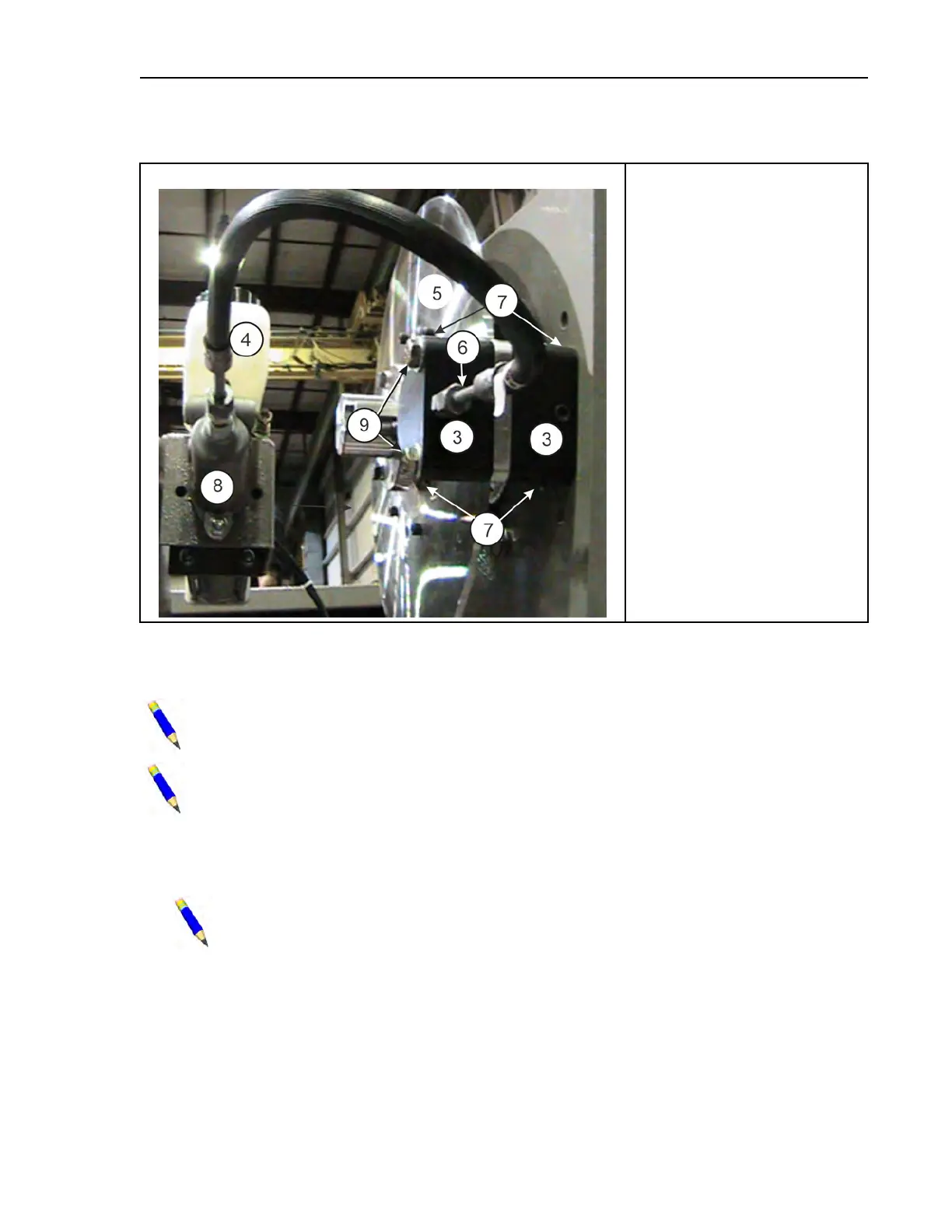

A typical hydraulic brake system (cont'd.)

The hydraulic cylinder and the caliper

The Inspection of the Brake

BNWUUM03.T01 0000277536 A.4 A.7 A.3 3/17/20 11:57 AM Released

NOTE: The brakes shown in this document can look different from your equipment.

NOTE: Do this inspection when the maintenance schedule tells it is necessary. Do this

inspection after you replace friction pads or do a caliper overhaul.

1. Examine the fluid in the reservoir. Change the hydraulic fluid if it smells, has contamination,

or has an unusual color. See Section : How to Change Hydraulic Fluid and Remove (Bleed)

Air from the Brake Circuit , page 43.

NOTE: Brake fluid can become defective from heat in the brake system. Brake fluid

absorbs water from air. Water in the brake system causes corrosion.

If necessary, add new DOT 3 fluid to 0.25 inch (6.35 millimeters) from the top of the reser-

voir. Follow the precautions on the container.

2. Examine the rotor disk surface (Figure 18: A typical hydraulic brake system, page 38 , item

5). Replace the disk if it is worn or if it is not flat.

3. Examine the brake pads (Figure 19: The Caliper Components, page 42 , item 4). To do this,

you will remove/replace the calipers and bleed the hydraulic system. See Section : How to Do

Drive Assemblies

Loading...

Loading...