34

Pellerin Milnor Corporation

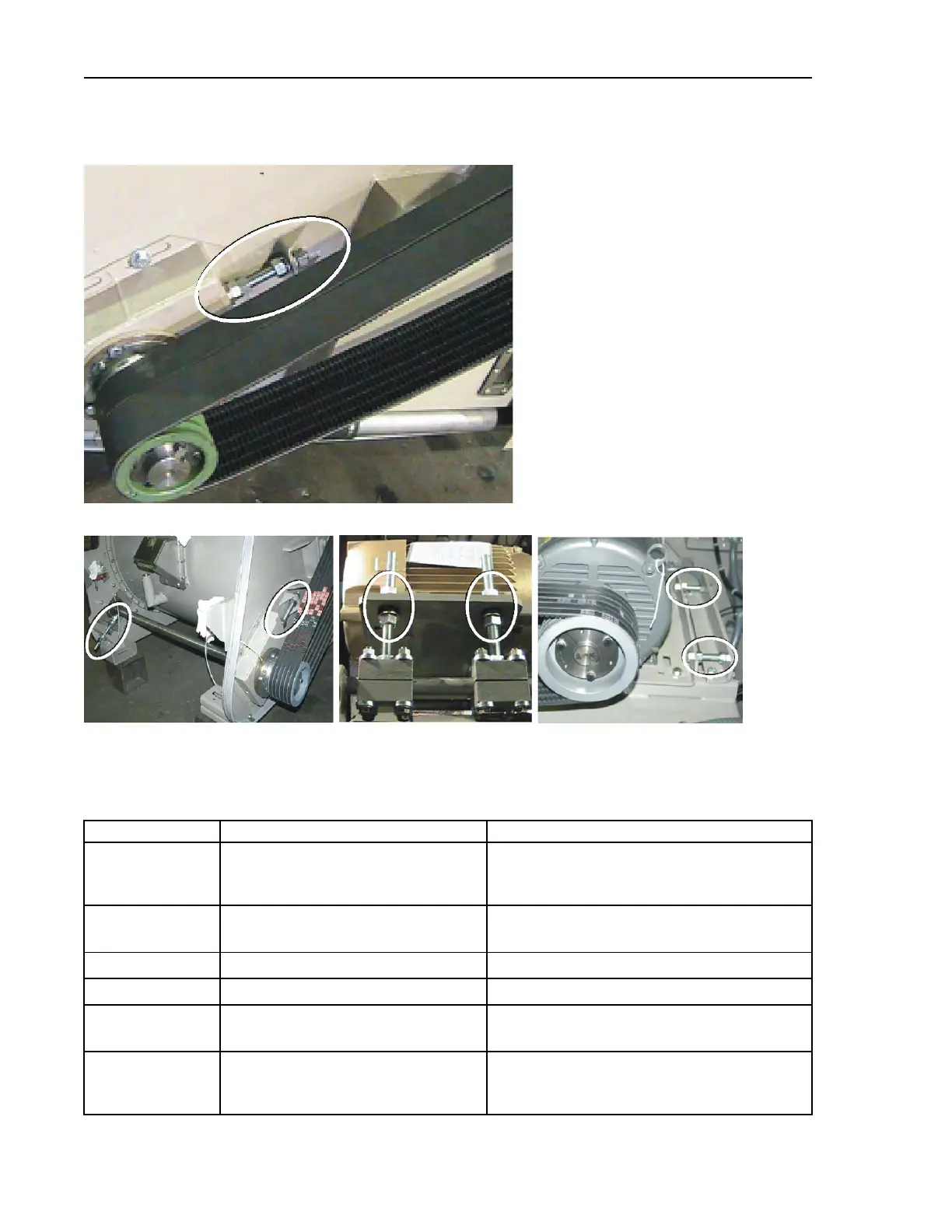

Figure 13. A Tension Mechanism that will not Change the Angle of the Pulleys

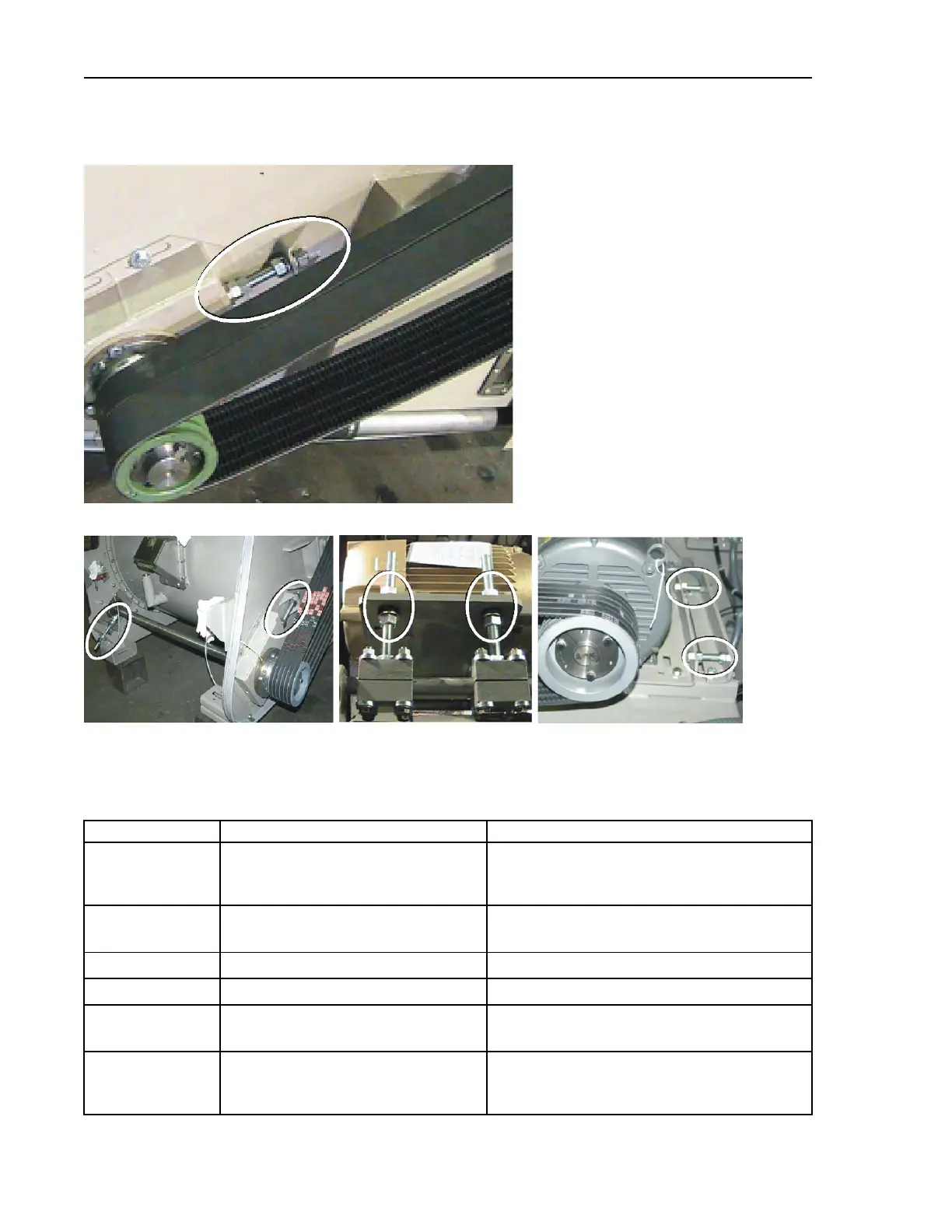

Figure 14. Some Pairs of Tension Mechanisms that Can Change the Angle of the Pulleys

How to Do Maintenance on Pulleys and Belts

BNUUUM02.C10 0000274653 A.4 A.3 3/6/20 4:49 PM Released

Table 17. Typical Tools for Pulley and Belt Maintenance

Tool

Function

Related Data

Torque wrench Make the bushing bolts the same

torque to get the minimum axial

run-out.

Figure 11 , item 2

Laser, straight

edge, or string

Align pulleys Tools are listed in order of preference.

Section and Figure 15

Bubble level Align shafts Section and Figure 16

Dial indicator

Measure run-out

Section and Figure 17

Sheave (pulley)

gage

Examine pulley wear Figure 8 . A source for this tool is www.

maskapulleys.com.

Infrared

thermometer

Examine belt temperature Section . A source for this tool is

http://www.infraredthermome-

tersale.com.

Drive Assemblies

Loading...

Loading...