66

Pellerin Milnor Corporation

BNWVUM02 / 2020124

BNWVUM02 0000278613 A.5 3/18/20 4:20 PM Released

Main Bearing and Seal Replacement for Divided Cylin-

der Machines

BNWVUM02.C01 0000278612 A.4 A.5 A.3 3/12/20 11:54 AM Released

This section applies to the front and rear cylinder shaft bearings of all divided cylinder machines

(Rapid Load, Staph Guard

®

, dye machines, etc.). It does not apply to jackshaft bearings, idler

shaft bearings or bearings on open pocket machines.

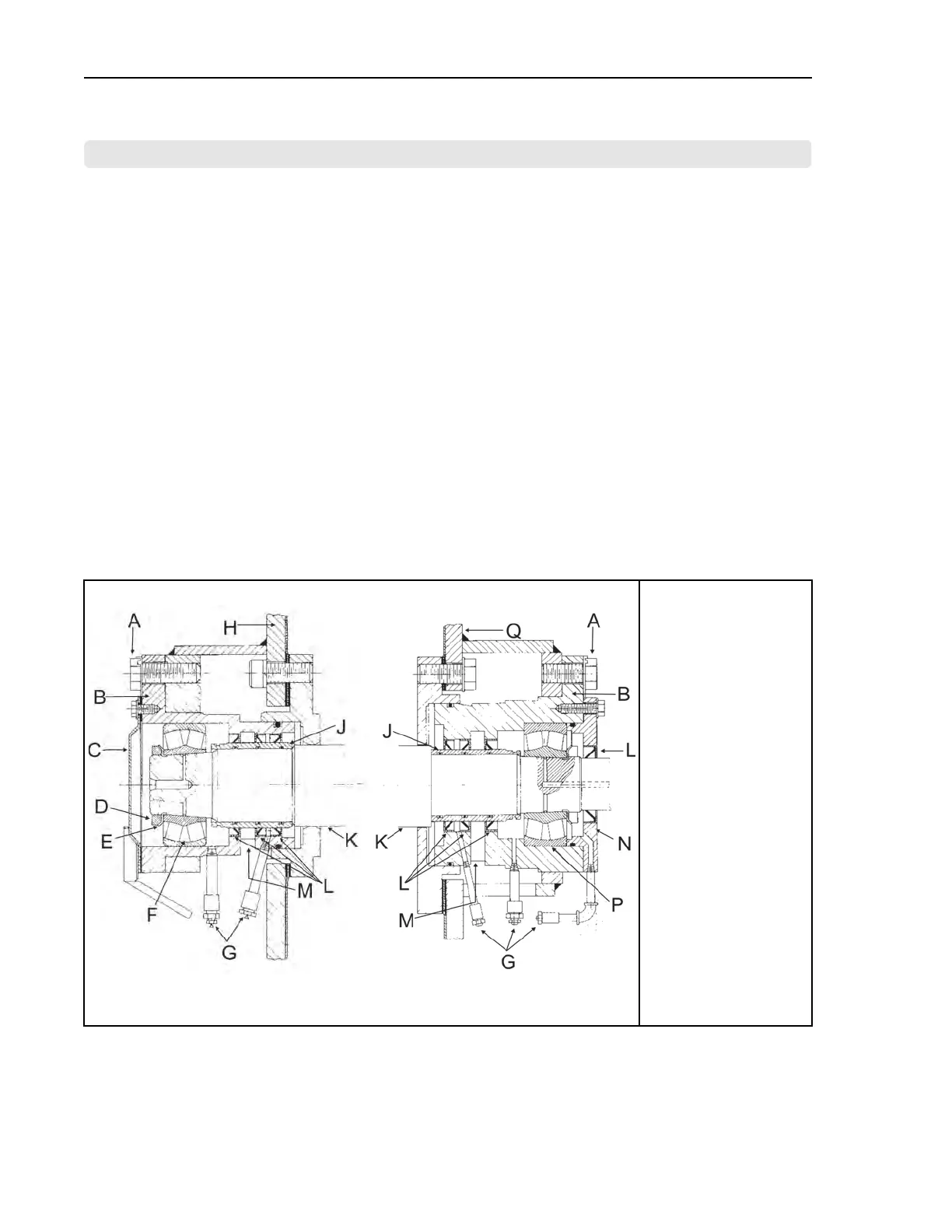

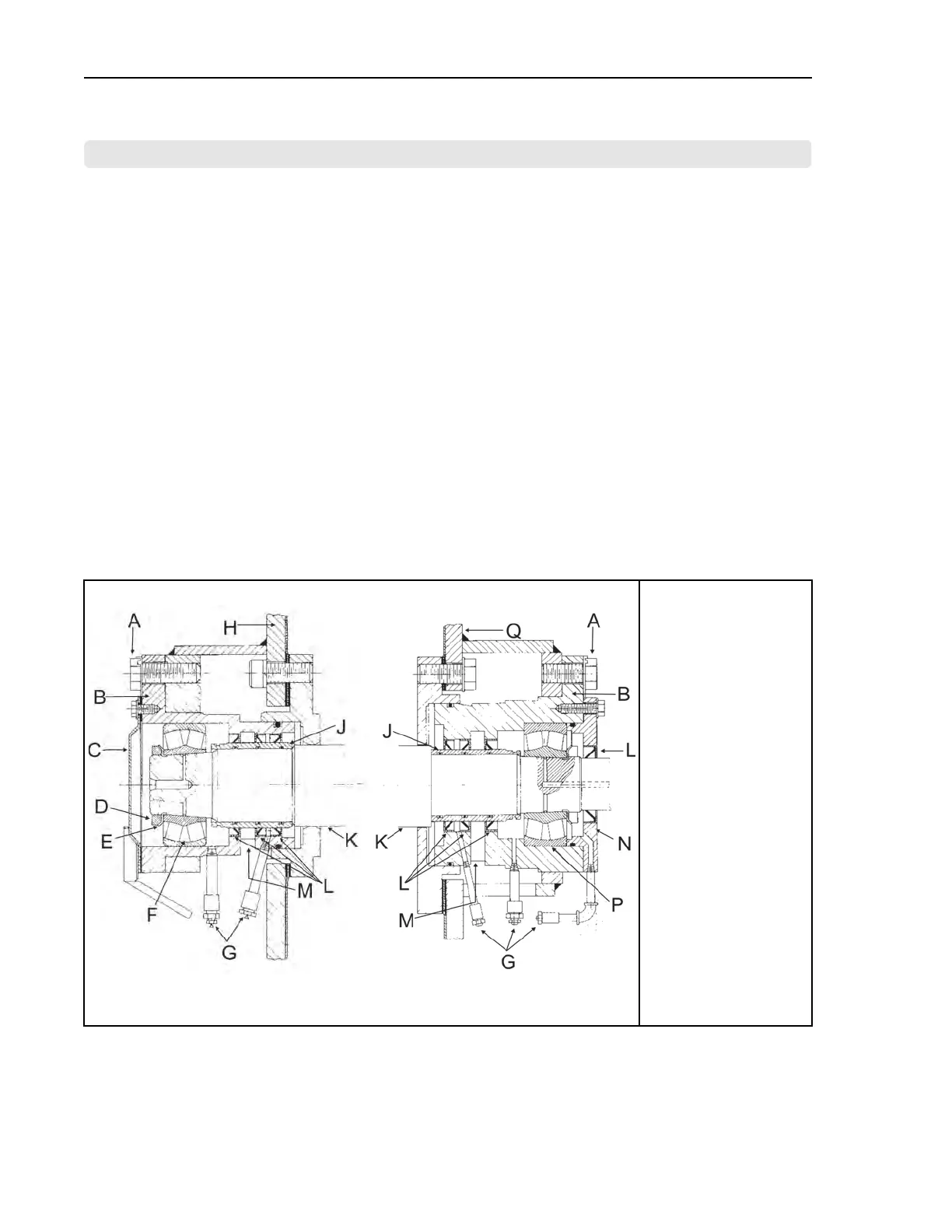

The bearings covered by this section are double row, spherical roller, self aligning bearings;

Koya, SKF, FMC, Torrington or equal. Referring to Figure 29 , the rear (clean side on Staph

Guard

®

models) bearing is firmly held in the bearing housing (bearing and seal carrier) by the

shaft seal holder, preventing axial movement. The front (soil side on Staph Guard

®

models) bear-

ing is free to move axially in the bearing housing to accommodate thermal expansion of the shaft

during operation and is thus the “floating” bearing. Both bearings are held in place on the tapered

portion of the shaft by a bearing lock washer and lock nut.

The front and rear bearings are each protected from contamination from wash water by three

spring loaded, lip type seals and a shaft seal leak off cavity (that carries off any water that leaks

past the main water seals) as shown in Figure 29 .

Figure 29. Cross Section View of Front and Rear Bearing Assemblies (Bearing Assembly for 60"

and 72" WED Shown. Others similar.)

Front Bearing Assembly

Rear Bearing Assembly

Legend

A...Cap bolt

B...Bearing housing

(bearing and seal

carrier)

C...Bearing cover

D...Bearing lock nut

E...Bearing lock

washer

F...Front bearing

(floating)

G...Bearing and seal

cavity leak offs

H...Shell front

J...Seal sleeves

K...Shaft

L...Seals

M...Shaft seal leak off

cavities

N...Shaft seal holder

P...Rear bearing

(fixed)

Q...Shell rear

Access to the bearings and seals for lubrication is provided by the various grease passages. Ex-

cess lubricant is excreted through the bearing and seal cavity leak offs as shown on Figure 29 .

The bearings and seals must be lubricated regularly and the leak off cavities flushed out

Drive Assemblies

Loading...

Loading...