38

Pellerin Milnor Corporation

• do an overhaul on the calipers,

• replace the hydraulic fluid,

• adjust the connection between the brake cylinder and the air cylinder.

For the first four types of maintenance, you must remove air from (bleed) the hydraulic circuit.

Section : Operation of Brake Systems, page 48 tells how to operate the disk brakes. You can use

it in some of the types of maintenance in this procedure.

WARNING: Risk of injury or death — A machine in operation without safety guards

is dangerous.

� You must be an approved maintenance technician.

� Use special caution when this instruction tells you to do work with

electrical power on. Remove power from the machine for all other mainte-

nance. Obey safety codes.

� Replace all guards and covers.

TIP: During parts of this procedure when you open up the calipers or hydraulic lines,

put a cloth under the calipers to catch hydraulic fluid and parts that will fall. For safety,

fully remove spilled hydraulic fluid after brake maintenance. This will help you easily

identify leaks.

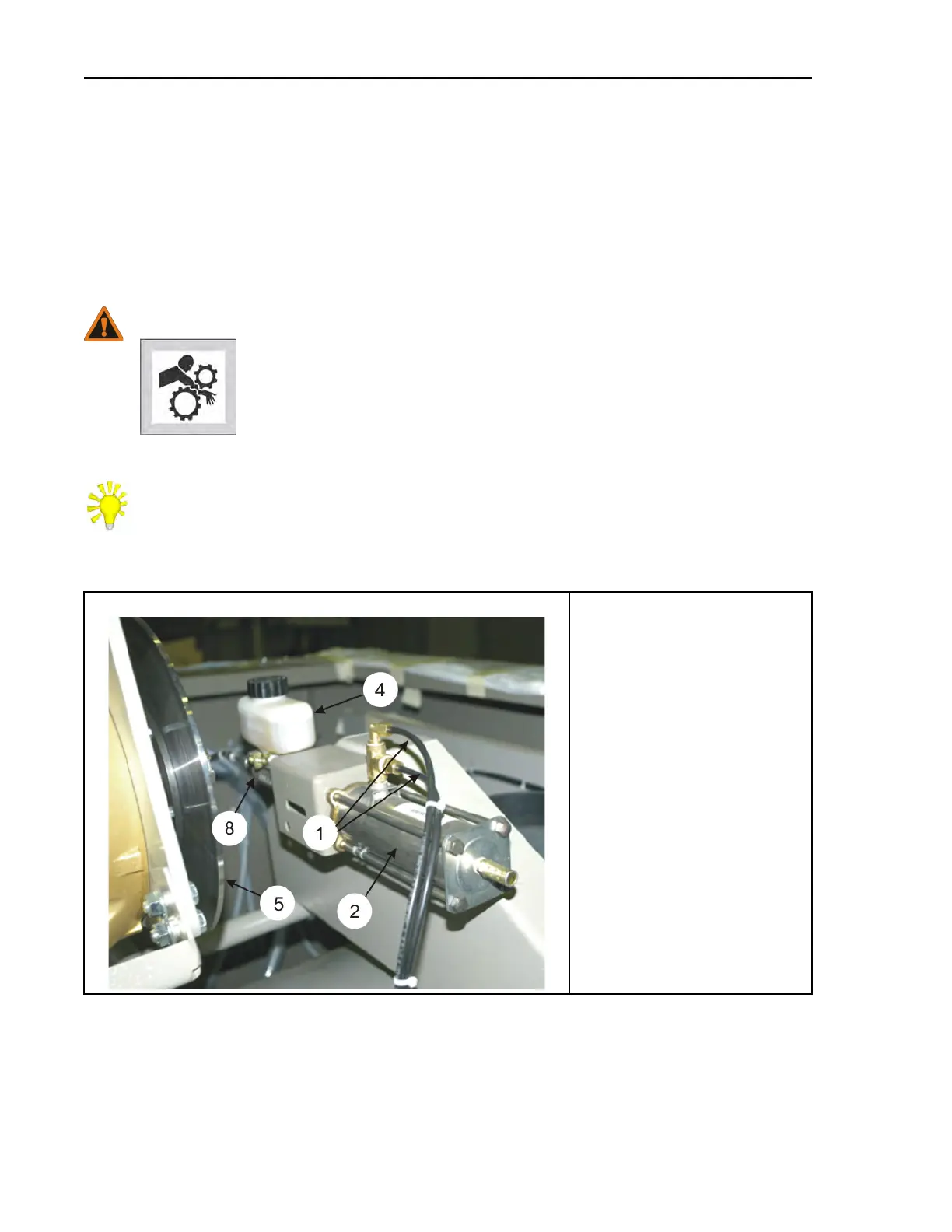

Figure 18. A typical hydraulic brake system

The air cylinder

Legend

1. Tubing for air

2. Air cylinder

3. Caliper body halves (Figure 19 ,

item 2)

4. Hydraulic reservoir

5. Rotor disk

6. Hydraulic inlet

7. Valves to drain fluid and bleed

the brake

8. Hydraulic cylinder

9. Bolts to attach the caliper (Figure

19 , item 1)

Drive Assemblies

Loading...

Loading...