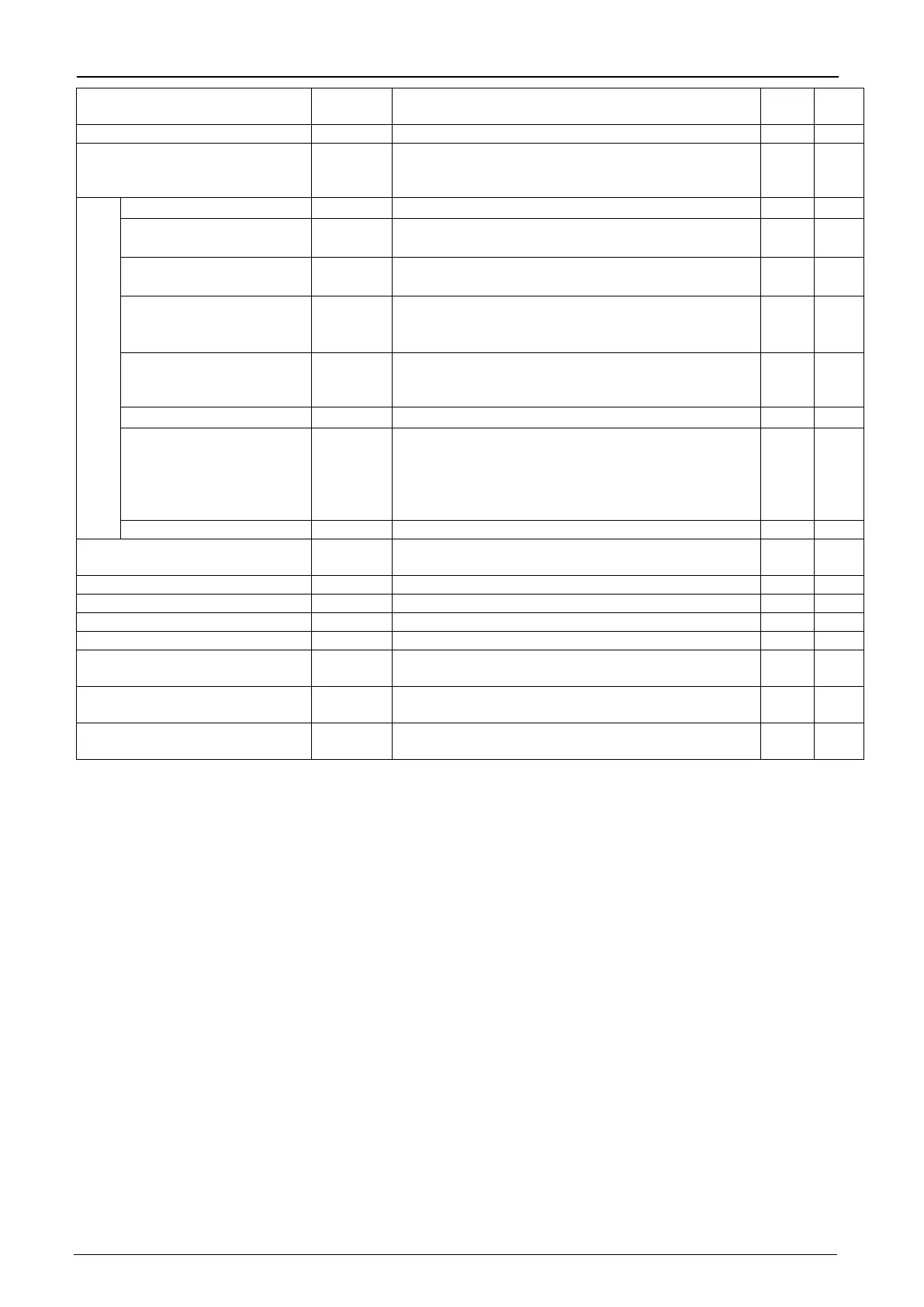

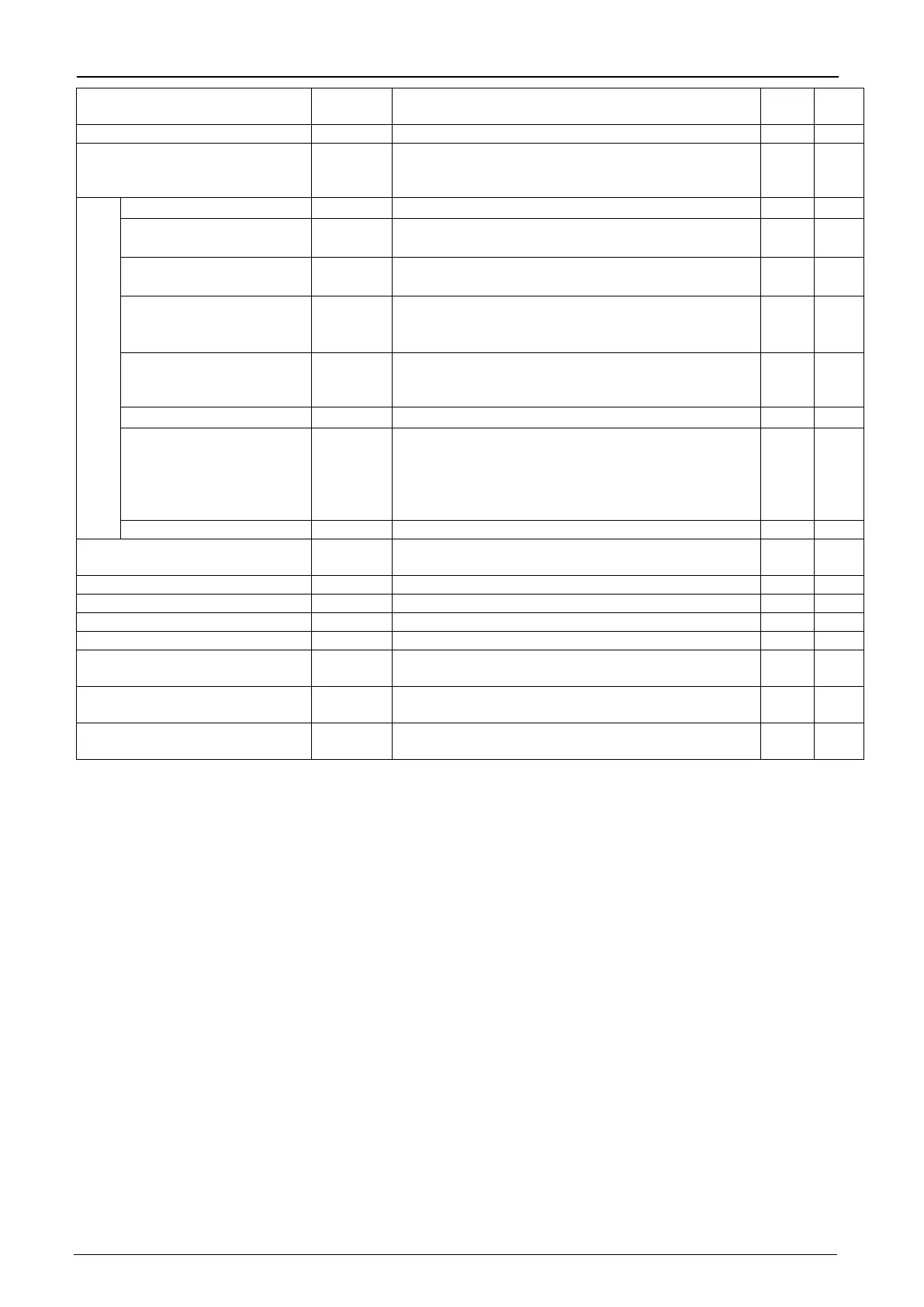

18-392 18-392

Ex-T coordinates speed

Speed of the Ex-T coordinates during execution of

the Ex-T control/the Ex-T spline interpolation

Ex-T coordinates position

The current position in the Ex-T coordinates

Spline path point

of adjusted speed

The path point number that speed adjustment has

occurred during execution of the spline

interpolation/the Ex-T spline interpolation

Speed of a tool center point

(

)

Remaining distance(FB)

[mm]

The remaining distance to the target position (in

mm) while the robot is moving

(

)

Tool point speed(CMD)

[mm/s]

Speed of a tool center point

(

)

Same as status variable values “M_RSpd”

Remaining

distance(CMD)

[mm]

The remaining distance to the target position (in

mm) while the robot is moving(command).

Same as status variable values “M_RDst”.

Gap of CMD and FB

[mm]

The gap of a command position and a feedback

position.

Same as status variable values “M_Fbd”.

Speed of a tool center point

(

)

Acceleration state(CMD)

The current acceleration/deceleration status.

(command)

[0=Stopped,1=Accelerating, 2 = Constant speed, 3

= Decelerating]

Same as status variable values “M_AclSts”.

Safety input

It turns ON when either safety input signal A or

safety input signal B is OFF.

Consecutive input signal for 32 points

Consecutive output signal for 32 points

Predictive maintenance score

(speed reducer abnormality)

Current abnormality score of reducer (wave gear

device)

Predictive maintenance score

(encoder data error)

Current abnormality score of encoder data

Predictive maintenance score

(encoder communication error)

Current abnormality score of encoder

communication

※High :High speed communication Ord :Ordinary communication

18.1.4. Starting

From the project tree, double-click [Tool] -> [Oscillograph]

Loading...

Loading...