P/N 330654-E 01/2018 COPYRIGHT © Dansensor A/S

36 User Guide EN Lippke 4000/4500

Burst test

A Burst test checks the strength of a package sealing by increasing the pressure in the package until it

bursts. The Burst test is compliant with ASTM F2054.

CAUTION! As the bursting of the test package may lead to considerable noise, we

recommend wearing hearing protection.

NOTE! When testing filled packages, precautions may be necessary to ensure that the

product does not contaminate the operator or the system. Depending on the package

contents, the use of safety glasses may be advisable. A protective hood placed over the

package may offer additional protection.

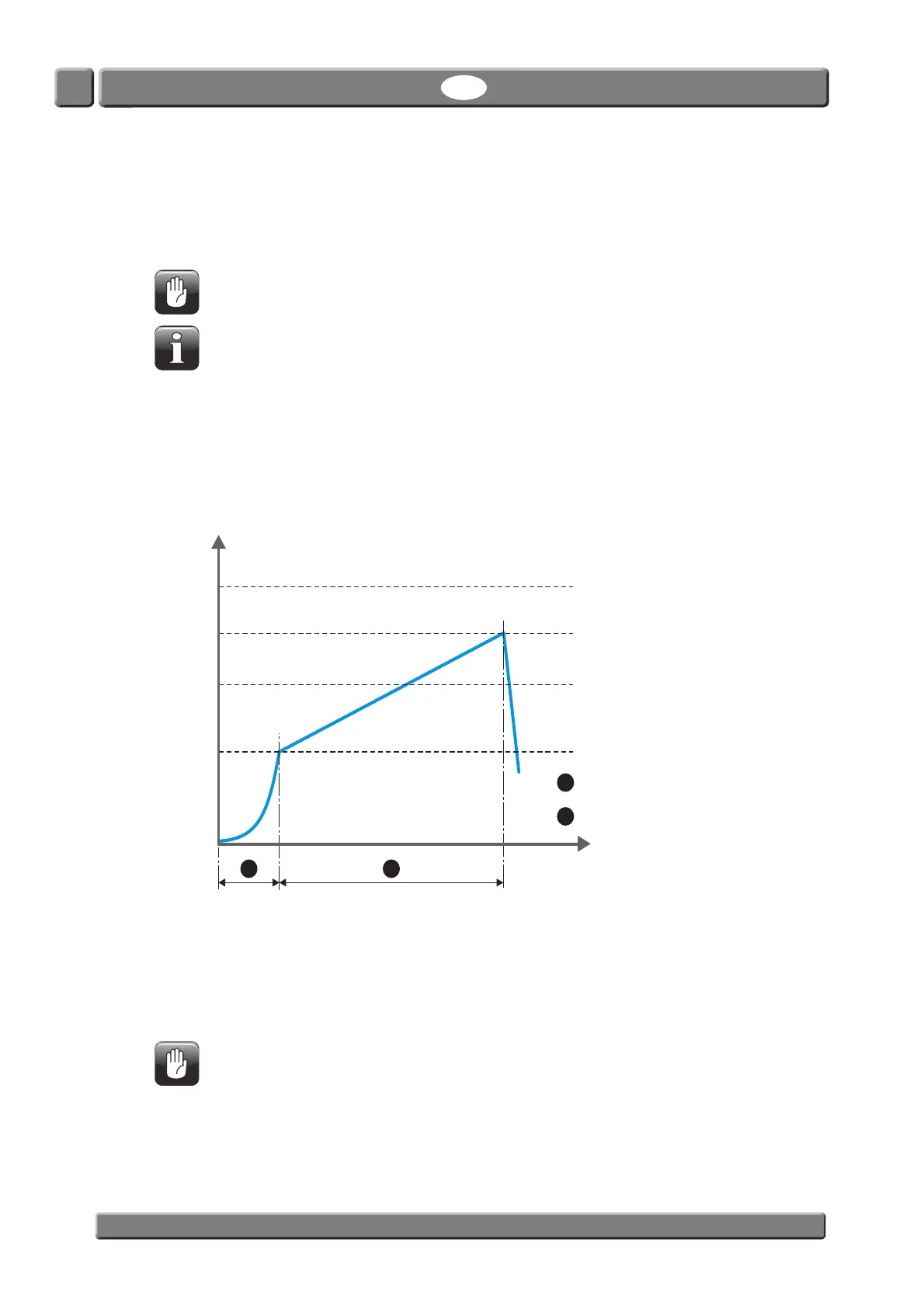

A Burst test is divided into 2 phases:

The package is inflated to the set pre-fill pressure.

The pressure in the package is increased at the pre-set rate until the package bursts or until the

maximum specified pressure is reached.

The results from the Burst test are:

• Measured burst pressure (if the package bursts)

• Package burst time (

)

• PASS - if the package bursts within the pre-set burst limits

• FAIL - if the package bursts outside the pre-set burst limits.

CAUTION! If the package did not burst, it is still under pressure! Remove the package

carefully; a sudden pressure drop will occur when it is removed.

Pressure

Time

Limit + (Upper-Limit)

Burst pressure

Limit - (Lower-Limit)

Pre filling pressure (Fill pressure)

[mbar]

[sec]

= Inflating to pre-fill pressure

= Linear pressure increase

1

12

2

Loading...

Loading...