P/N 330654-E 01/2018 COPYRIGHT © Dansensor A/S

48 User Guide EN Lippke 4000/4500

Bubble test

(Requires the Creep Test option)

The Bubble test is only available for the Lippke 4500 and has two purposes; one is to locate the

placement of a hole in a package. To do this place the package (with septum and needle) under water.

Secondly you can test for example that a Tyvek package functions as intended, meaning that it only leaks

within a specific pressure range. This test also requires for the package to be under water.

A Bubble test inflates the package to a specific pressure and maintains this pressure for a specified time

period. The Bubble test is compliant with ASTM F2096.

CAUTION! It is possible that the package will burst during a Bubble test. Please note that

the pressure may not drop to a low level immediately after the test.

NOTE! When testing filled packages, precautions may be necessary to ensure that the

product does not contaminate the operator or the system. Depending on the package

contents, the use of safety glasses may be advisable. A protective hood placed over the

package may offer additional protection.

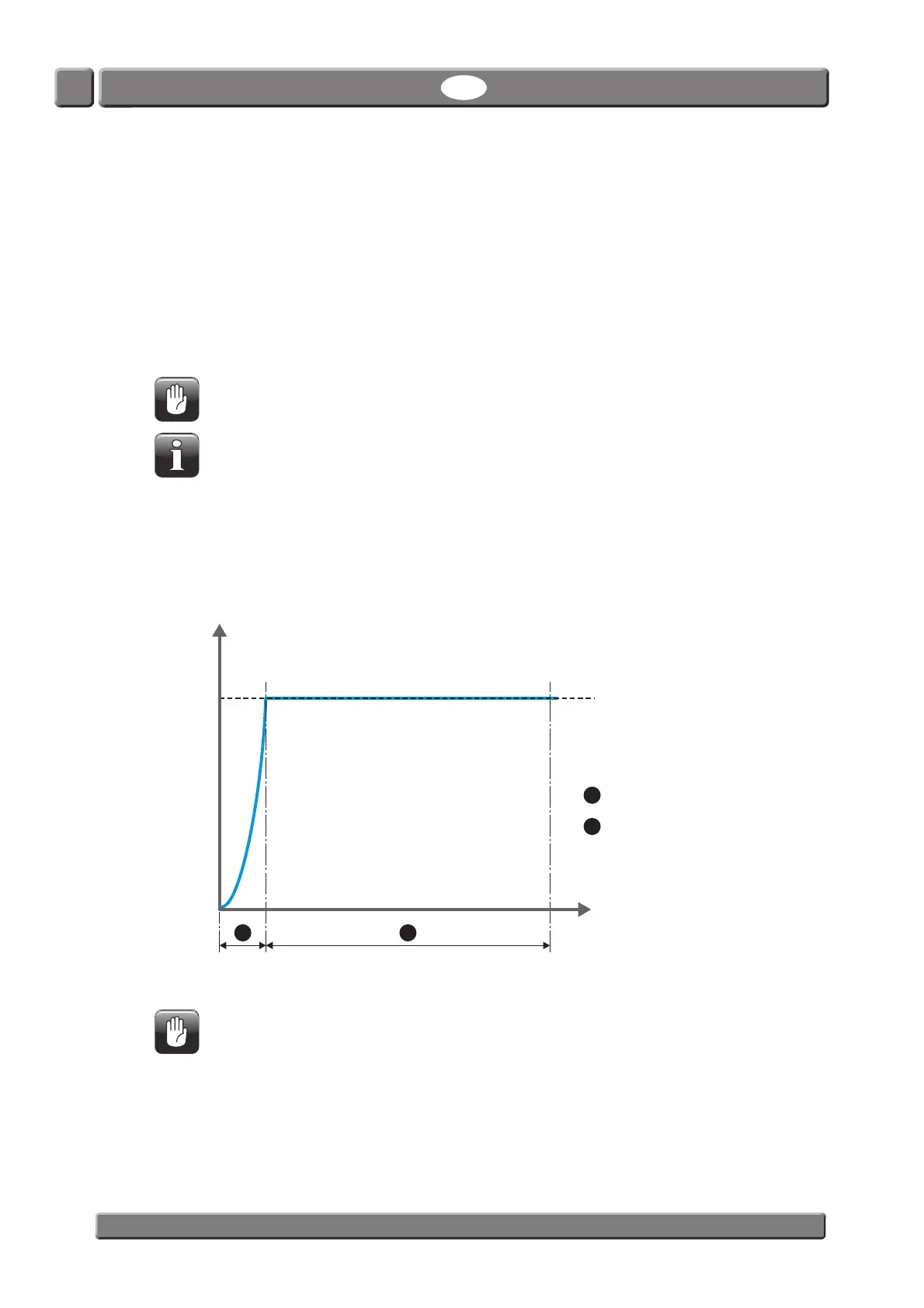

A Bubble test is divided into 2 phases:

The package is inflated to the test pressure.

The test pressure is maintained for a fixed period of time.

When test ends you must select whether the test was passed or not.

CAUTION! If the package did not burst, it is still under pressure! Remove the package

carefully; a sudden pressure drop will occur when it is removed.

Pressure

Time

Test pressure

= Inflating to test pressure

= Testing (Test time)

[mbar]

[sec]

1

12

2

Loading...

Loading...