Dansensor A/S COPYRIGHT © P/N 330654-E 01/2018

Lippke 4000/4500 EN User Guide 39

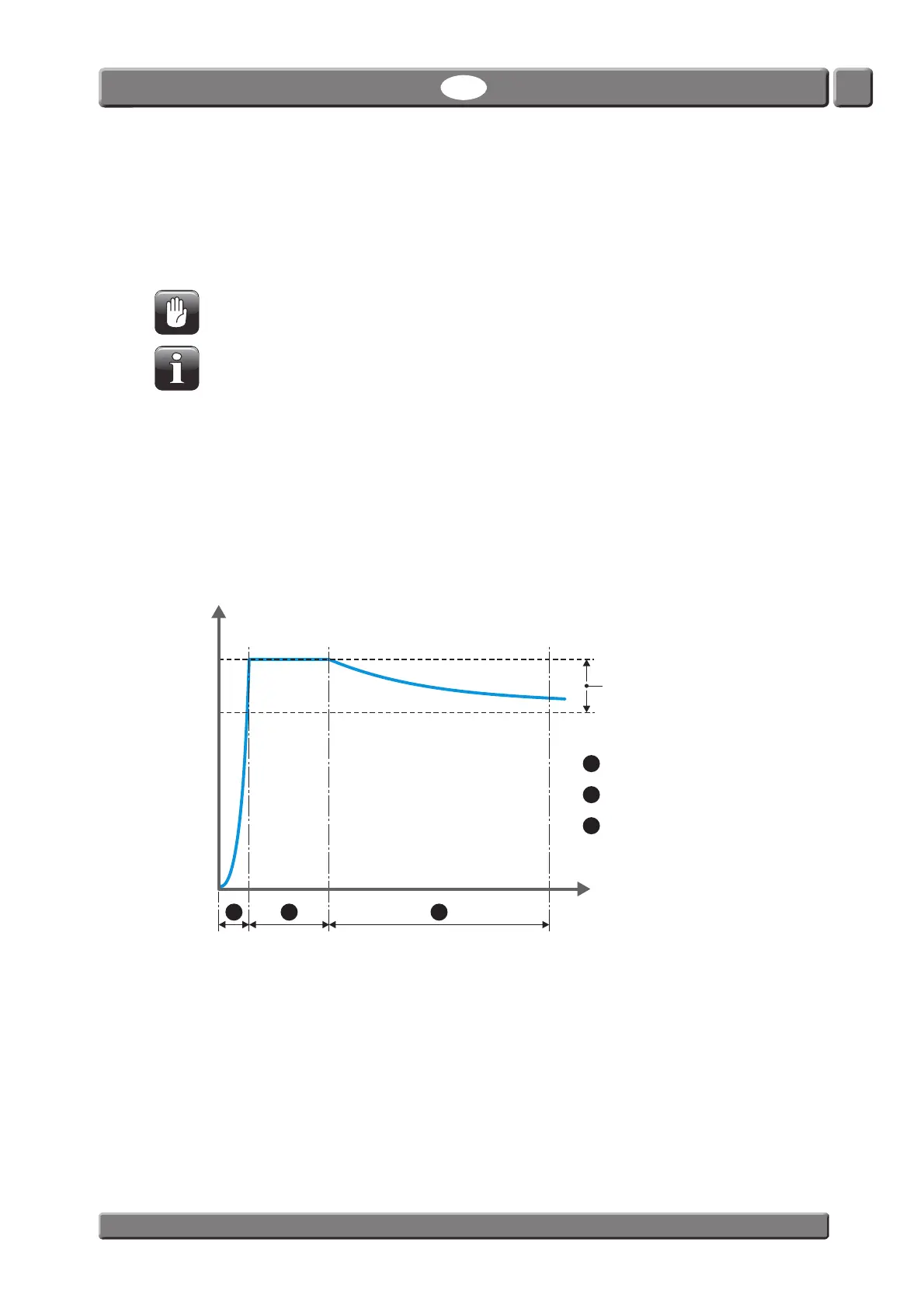

Leak test

A Leak test checks a package for leaks. The package is inflated to a predetermined pressure (about 30-

50% of the package’s burst pressure) and then the pressure loss is monitored to determine whether or

not there is a leak. The Leak test is compliant with ASTM F2095.

CAUTION! During a Leak test the package will normally not burst and so the pressure in the

package may not drop to a low level immediately after the test.

NOTE! When testing filled packages, precautions may be necessary to ensure that the

product does not contaminate the operator or the system. Depending on the package

contents, the use of safety glasses may be advisable. A protective hood placed over the

package may offer additional protection.

A Leak test is divided into 3 phases:

The package is inflated to the test pressure.

The test pressure is maintained and stabilised.

Pressure regulation stops and valves are closed. The pressure drop is measured during the test

time. The test passes if the pressure drop is below setting and fails if pressure drop is larger than

setting.

The results from the Leak test are:

•Pressure drop

• PASS - if the pressure drops less than allowed

•FAIL - if the pressure drops more than allowed

Pressure

Time

Test pressure

Max. allowed pressure drop

Fail limit

= Inflating to test pressure

= Pressure stabilisation

= Testing

[mbar]

[sec]

1

12 3

2

3

Loading...

Loading...