NIBE FIGHTER 1250

B

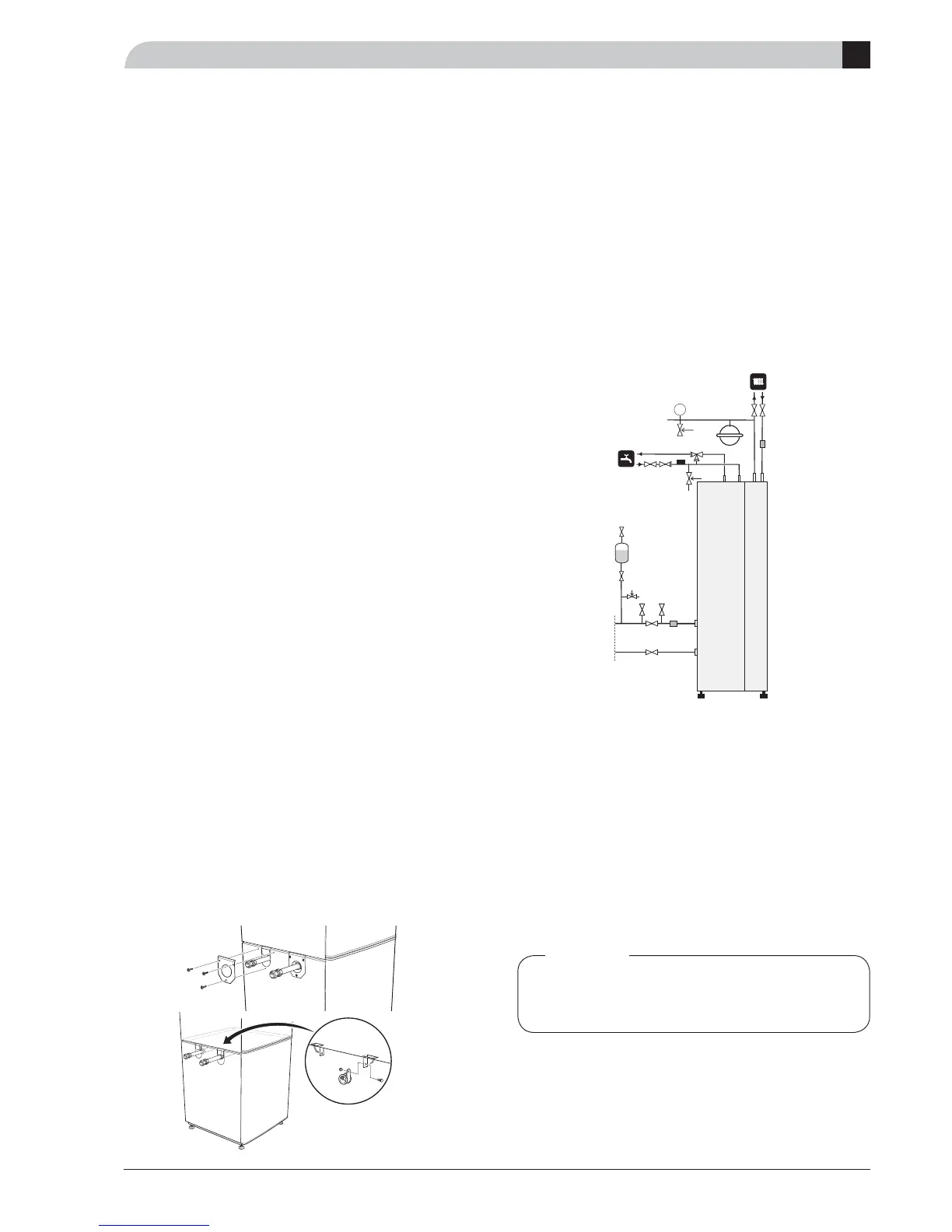

Connecting the brine

When dimensioning the collector, consideration must

be given to the geographical location, type of rock and

ground and the degree of coverage provided by the heat

pump.

When installing the collector hose ensure it rises con-

stantly towards the heat pump to avoid air pockets. If

this is not possible, install high points to vent the air.

All brine lines must be insulated.

The level vessel (NK) must be installed as the highest

point in the brine system and on the incoming pipe be-

fore the brine pump.

The accompanying safety valve (SÄV) must be installed

under the level vessel as illustrated. The overfl ow pipe

from the safety valve must be routed enclosed along

its entire length to prevent water pockets and be frost

proof.

Note that condensation may drip from the level ves-

sel. Position the vessel so that this does not harm other

equipment.

As the temperature of the brine system can fall below 0

°C it must be protected against freezing down to -15 °C.

One litre of ready mixed brine per metre of collector hose

(applies when using PEM-hose 40 x 2.4 PN 6.3) is used as a

guide value when making the volume calculation.

Details of the antifreeze used must be shown on the

level vessel.

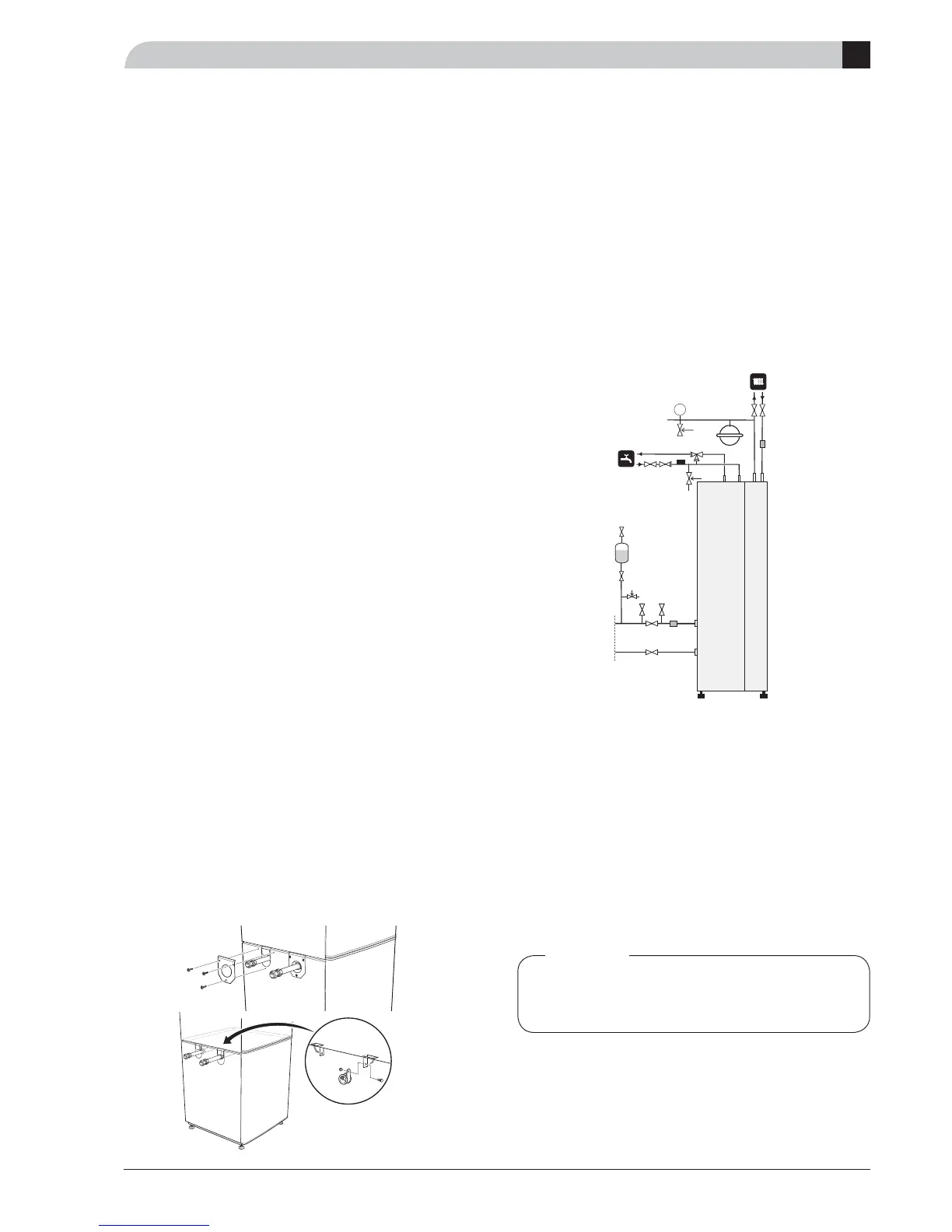

The brine system may be connected from the left or

from the right.

The lower side panels are swapped over to suit the cho-

sen connection option. The enclosed connecting pipes

for the brine are secured using the clips in the punched

tabs that are folded down on the side in question.

Shut-off valves should be installed as close to the heat

pump as possible.

Fit the supplied particle fi lter on the incoming pipe.

In the case of connection to an open groundwater system,

an intermediate frost-protected circuit must be provided,

because of the risk of dirt and freezing in the evaporator.

This requires an extra heat exchanger.

Cover plates

The enclosed cover plates are fi tted on the side panel, see

fi gure.

Connecting the heating medium

Pipe connections for the heat medium side are made at

the top.

All required safety devices, shut-off valves (as close to

the heat pump as possible), and particle fi lter (supplied)

must be fi tted.

The safety valve must have a maximum 2.5 bar open-

ing pressure and be installed on the outgoing heat-

ing medium as illustrated. The overfl ow pipe from the

safety valve must be routed enclosed along its entire

length to prevent water pockets and be frost proof.

When connecting to a system with thermostats on all

radiators, a relief valve must be fi tted, or some of the

thermostats must be removed to ensure suffi cient fl ow.

Connecting the hot water heater

The hot water heater in the heat pump must be supplied

with necessary set of valves.

There must be a mixer valve if the temperature exceeds

60 °C.

The safety valve must have a maximum 9.0 bar open-

ing pressure and be installed on the incoming domestic

water line as illustrated. The overfl ow pipe from the

safety valve must be routed enclosed along its entire

length to prevent water pockets and be frost proof.

Loading...

Loading...