NIBE FIGHTER 1250

The heat pump’s sub system and its function

Some heat pump technology

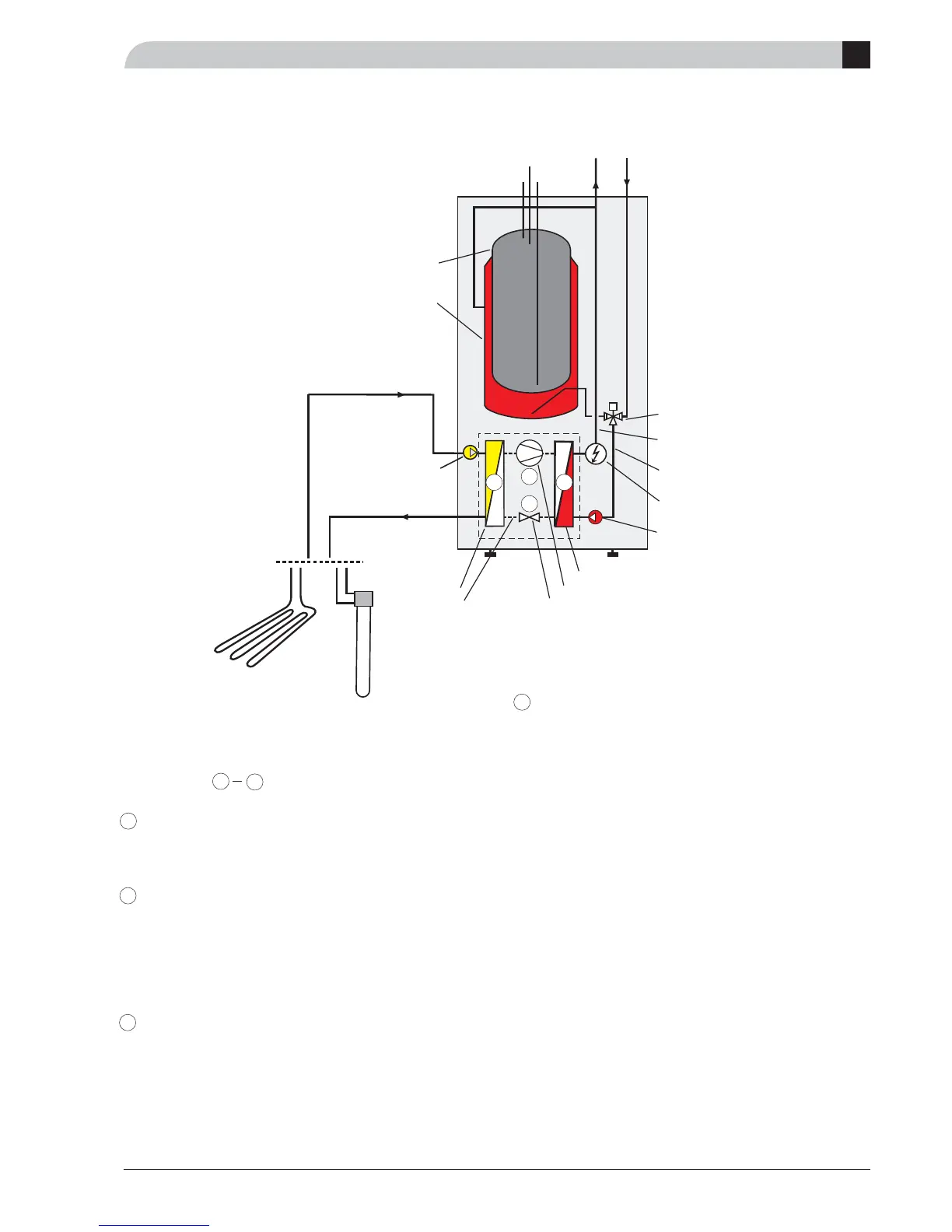

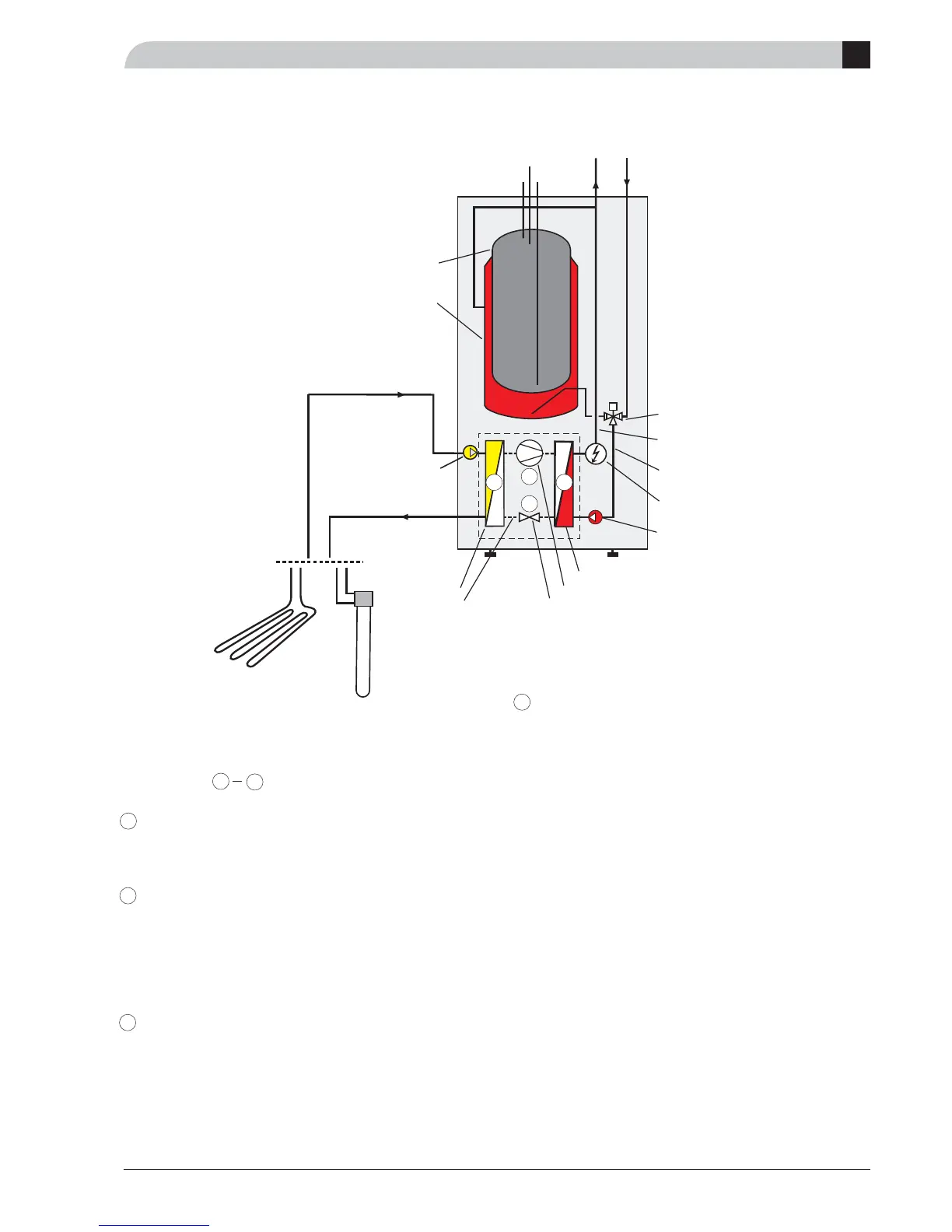

The heat pump functions can easily be divided into four

sub processes:

1. Fluid ( the refrigerant) that is used in our heat pump

boils* at a very low temperature in the evaporator. The

heat retrieved by the circulating fl uid (the brine) from

the ground/rock/lake is enough to cause it to boil.

2. The steam (gas) that is produced when the refrigerant

boils, is drawn into the speed controlled compressor.

There it is compressed just enough for the relevant heat

demand. As the pressure of the gas increases it also be-

comes extremely hot.

(The low temperature refrigerant has been converted to

a high tempered gas)

3. The hot gas is routed into a heat exchanger ( condenser)

where it releases its heat into the heating system’s water

( heating medium). It passes through the same con-

denser but on the other side of a separating wall so that

the mediums do not mix.

When heat is transferred to the heating medium the gas

is cooled and converted to a fl uid again (condenses).

A

The heat pump’s sub system and its function

4. The expansion valve fi nally reduces the pressure of

the fl uid (refrigerant, so that it can be re-boiled at a low

temperature) at the same time as it only releases the

exact amount of fl uid to the evaporator that is to be

reheated and evaporated by the heat retrieved from the

ground.

The described process is repeated over and over and

only the compressor and circulation pumps require elec-

trical energy during normal operation.

The energy for the heating system - and domestic

hot water is obtained, as described above, from the

ground. The heat pump’s COP value determines how

effectively this is carried out( heating factor). The value is

a measurement of how much heat is obtained in rela-

tion to consumed electrical energy.

*) The boiling point of different fl uids varies but the pres-

sure in the vessel is important. Water boils at +100 °C in

a saucepan on a hob but would have done so at +80 °C

if the air pressure in the room had been half as high. This

is a property that is used within heat pump technology.

Note that all material that has a greater temperature

than -273 °C contains heat that is possible to recover, the

greater the temperature of the refrigerant the more ef-

fectively this can be carried out.

1

2

3

1

4

Värmebärarpump

(varvtalsstyrd)

Eltillsats

Växelventil

Värmebärare fram

(VBF)

Värmebärare retur

(VBR)

Förångare

Köldbärarpump

(varvtalsstyrd)

Kompressor (varvtalsstyrd)

Kondensor

VV KV

Expansionsventil

Köldmediei

Värme

returledning

Dubbelmantel

Köldbärare in (KBin)

Köldbärare ut (KBut)

Varmvattenberedare

Värme

framledning

2

1 3

4

HWC

HW CW

Heating flow

line

Heating return

line

Hot water heater

Double jacket

Brine in (KBin)

Brine pump (speed

controlled)

Brine out (KBut)

Evaporator

Refrigerant

Expansion valve

Compressor (speed controlled)

Condenser

Heating medium

pump (speed control-

led)

Electrical addition

Heating medium

return (VBR)

Heating medium flow

(VBF)

Shuttle valve

4

Loading...

Loading...