3. Instructions

644

CS/CJ/NSJ Series Instructions Reference Manual (W474)

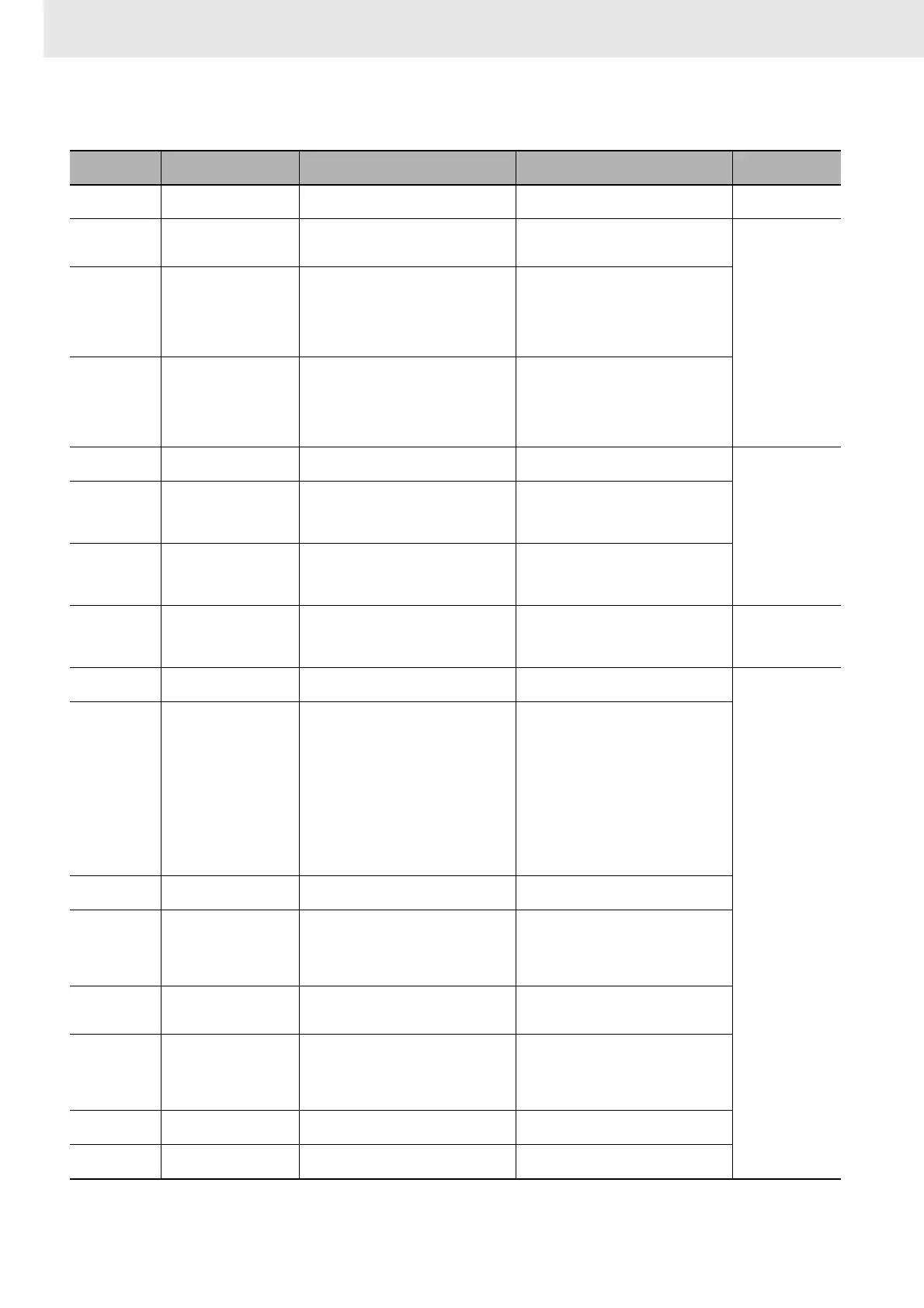

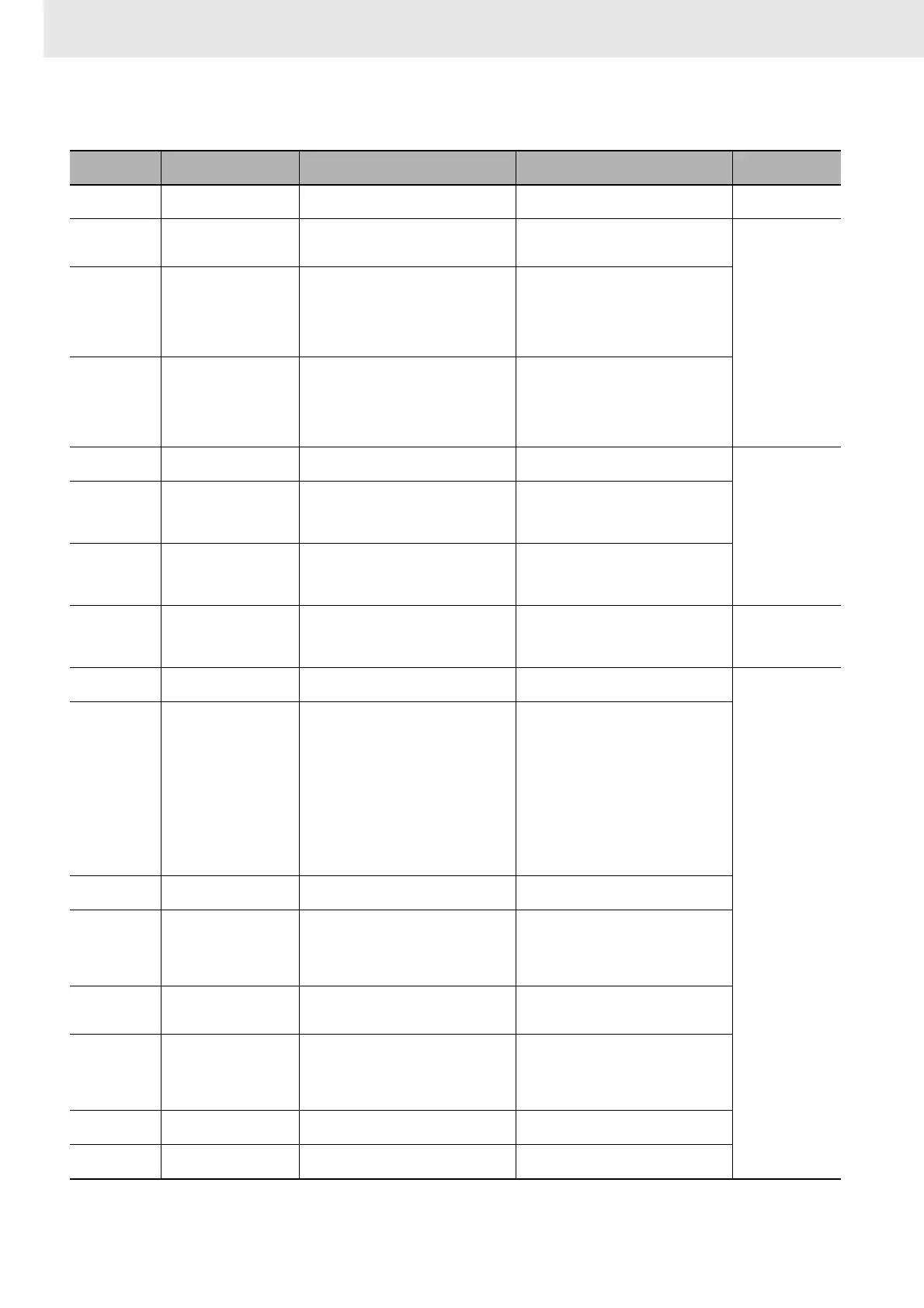

PID Parameter Settings

Control data Item Contents Setting range

Change with ON

input condition

C Set value (SV) The target value of the process being

controlled.

Binary data (of the same number of bits as

specified for the input range)

Allowed

C+1 Proportional band The parameter for P action expressing the

proportional control range/total control

range.

0001 to 270F hex (1 to 9999);

(0.1% to 999.9%, in units of 0.1%)

Can be changed

with input condition

ON if bit 1 of C+5

is 1.

C+2 Tik

Integral Constant

A constant expressing the strength of the

integral action. As this value increases, the

integral strength decreases.

0001 to 1FFF hex (1 to 8191);

(9999 = Integral operation not executed)

When “1” is specified for the

integral/differential constant: 1 to 8191

When “9” is specified: 0.1 to 819.1 s

(See note 1.)

C+3 Tdk

Derivative Constant

A constant expressing the strength of the

derivative action. As this value increases,

the derivative strength decreases.

0001 to 1FFF hex (1 to 8191);

(0000 = Derivative operation not executed)

When “1” is specified for the

integral/differential constant: 1 to 8191

When “9” is specified: 0.1 to 819.1 s

(See note 1.)

C+4 Sampling period (τ) Sets the period for executing the PID

action.

0001 to 270F hex (1 to 9999);

(0.01 to 99.99 s, in units of 10 ms)

Not allowed

Bits 04 to 15 of

C+5

2-PID parameter (α) The input filter coefficient. Normally use

0.65 (i.e., a setting of 000). The filter

efficiency decreases as the coefficient

approaches 0.

000 hex: α = 0.65

Setting from 100 to 163 hex means that

the value of the rightmost two digits is set

from α= 0.00 to α= 0.99. (See note 2.)

Bit 03 of C+5 Manipulated variable

output designation

Designates the manipulated variable

output when the PV equals the SV.

This setting is enabled when there is no

integral operation.

0: Output 0%

1: Output 50%

Bit 01 of C+5 PID constant change

enable setting

The timing of enabling changes made to

the proportional band (P), integral

constant (Tik), and derivative constant

(Tdk) for use in PID calculations.

0: At start of PID instruction execution

1: At start of PID instruction execution and

each sampling period

Allowed

Bit 00 of C+5 PID forward/reverse

designation

Determines the direction of the

proportional action.

0: Reverse action

1: Forward action

Not allowed

Bits 13 to 14 of

C+6

ID starting integral

manipulated variable

designation (unit version

4.0 or later only)

Determines the initial integral manipulated

variable when PID control is started (i.e.,

when the input turns ON).

Bit 14 = 0 and bit 13=0:

Start from same integral manipulated

value as manipulated variable output

designation (Pre-Ver. 4.0 operation).

Bit 14 = 0 or 1 and bit 13 = 1:

Bumpless operation (i.e., start from an

integral manipulated variable that will not

abruptly change the manipulated variable

output and result in a continuous change).

Bit 14 = 1 and bit 13 = 0:

Start with integral manipulated variable =

0.

Bit 12 of C+6 Manipulated variable

output limit control

Determines whether or not limit control will

apply to the manipulated variable output.

0: Disabled (no limit control)

1: Enabled (limit control)

Bits 08 to 11 of

C+6

Input range The number of input data bits. 0: 8 bits 5: 13 bits

1: 9 bits 6: 14 bits

2: 10 bits 7: 15 bits

3: 11 bits 8: 16 bits

4: 12 bits

Bits 04 to 07 of

C+6

Integral and derivative unit Determines the unit for expressing the

integral and derivative constants.

1: Sampling period multiple

9: Time (unit: 100 ms)

(See note 1.)

Bits 00 to 03 of

C+6

Output range The number of output data bits. 0: 8 bits 5: 13 bits

1: 9 bits 6: 14 bits

2: 10 bits 7: 15 bits

3: 11 bits 8: 16 bits

4: 12 bits

C+7 Manipulated variable

output lower limit

The lower limit for when the manipulated

variable output limit is enabled.

0000 to FFFF (binary)

(See note 3.)

C+8 Manipulated variable

output upper limit

The upper limit for when the manipulated

variable output limit is enabled.

0000 to FFFF (binary)

(See note 3.)

Loading...

Loading...