6-12

Deceleration to Stop

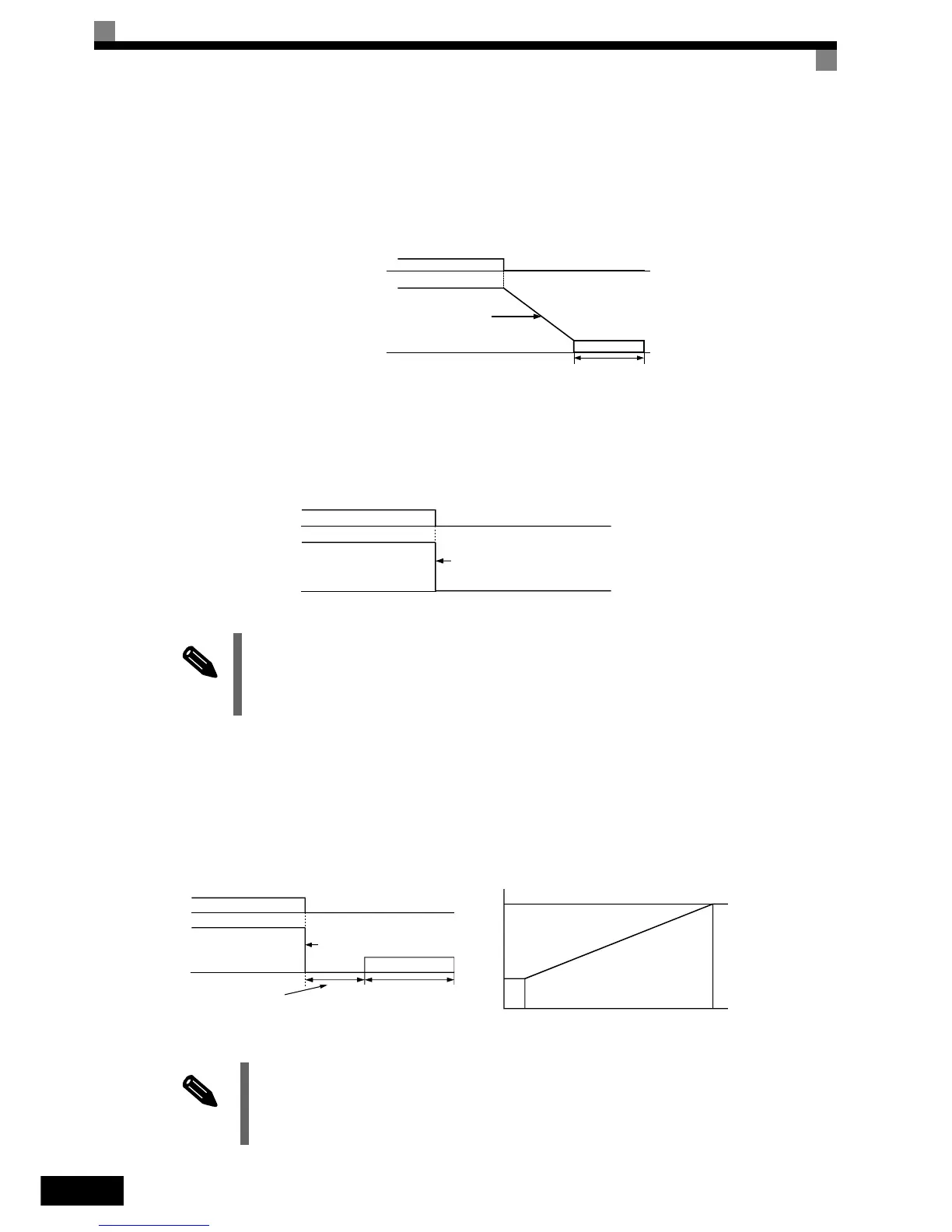

If the stop command is input (the run command is turned OFF) when b1-03 is set to 0, the motor decelerates to

stop according to the deceleration time that has been set. (Factory setting: C1-02 (Deceleration Time 1)).

If the output frequency when decelerating to stop falls below b2-01, the DC injection brake will be applied

using the DC current set in b2-02 for the time set in b2-04.

For deceleration time settings, refer to page 6-15, Setting Acceleration and Deceleration Times.

Fig 6.14 Deceleration to Stop

Coast to Stop

If the stop command is input (i.e., the run command is turned OFF) when b1-03 is set to 1, the Inverter output

voltage is switched off. The motor coasts to stop.

Fig 6.15 Coast to Stop

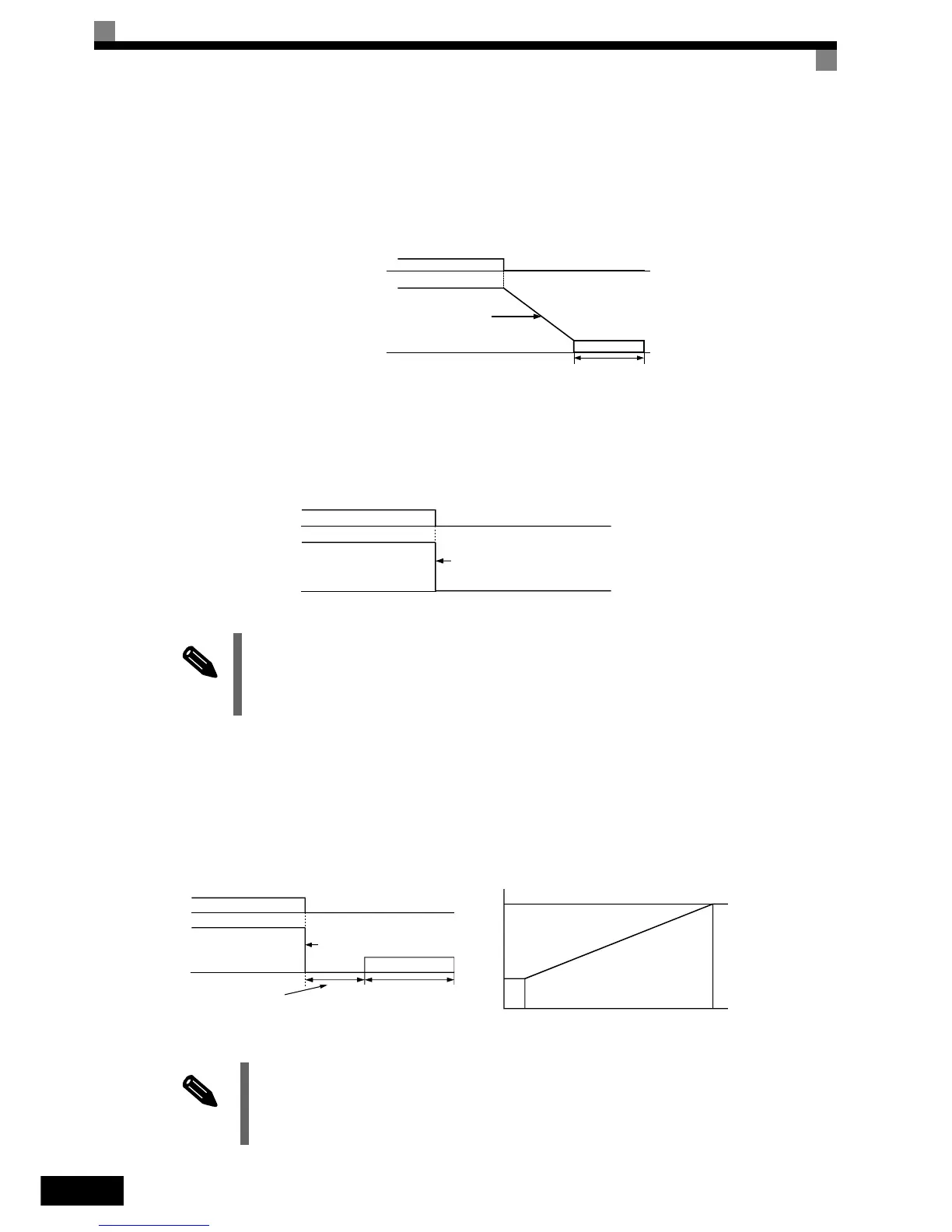

DC Braking Stop

After the stop command is input and the minimum baseblock time (L2-03) has elapsed, DC injection will be

applied to the motor. The applied DC injection current is programmed in parameter b2-02. The DC injection

brake time depends on the set value of b2-04 and on the output frequency at the moment the stop command is

input.If the output frequency was higher than 10% of the maximum output frequency (E1-04) the DC injection

time is lengthened like shown in the figure below.

Fig 6.16 DC Injection Braking Stop

NOTE

After the stop command is input, run commands are ignored until the Minimum Baseblock Time

(L2-03) has elapsed.

NOTE

Lengthen the Minimum Baseblock Time (L2-03) when an overcurrent (OC) occurs during stopping.

ON OFF

Decelerates to stop using the

active deceleration time

DC injection brake

time at stop (b2-04)

DC injection brake

Run Command

Output

Frequency

ON OFF

Run command

Output frequency

Inverter output frequency

interrupted

Output frequency at

stop command input

100% (maximum output frequency

10%

b2-04

b2-04 x 10

DC injection brake time

Run command

Output frequency

DC injection brake

ON

OFF

Inverter output voltage interrupted

Minimum baseblock

time (L2-03)

DC injection brake time

Loading...

Loading...