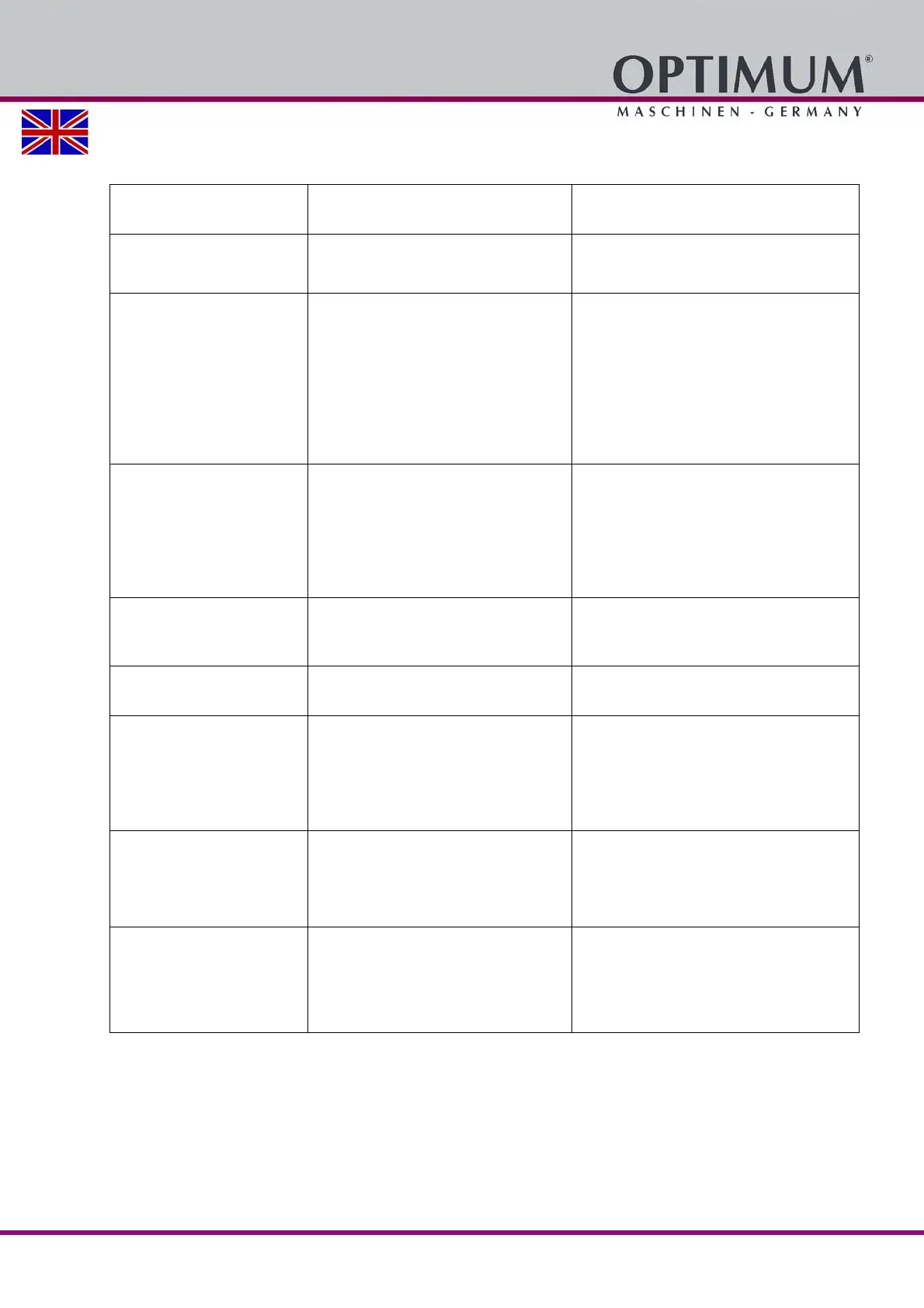

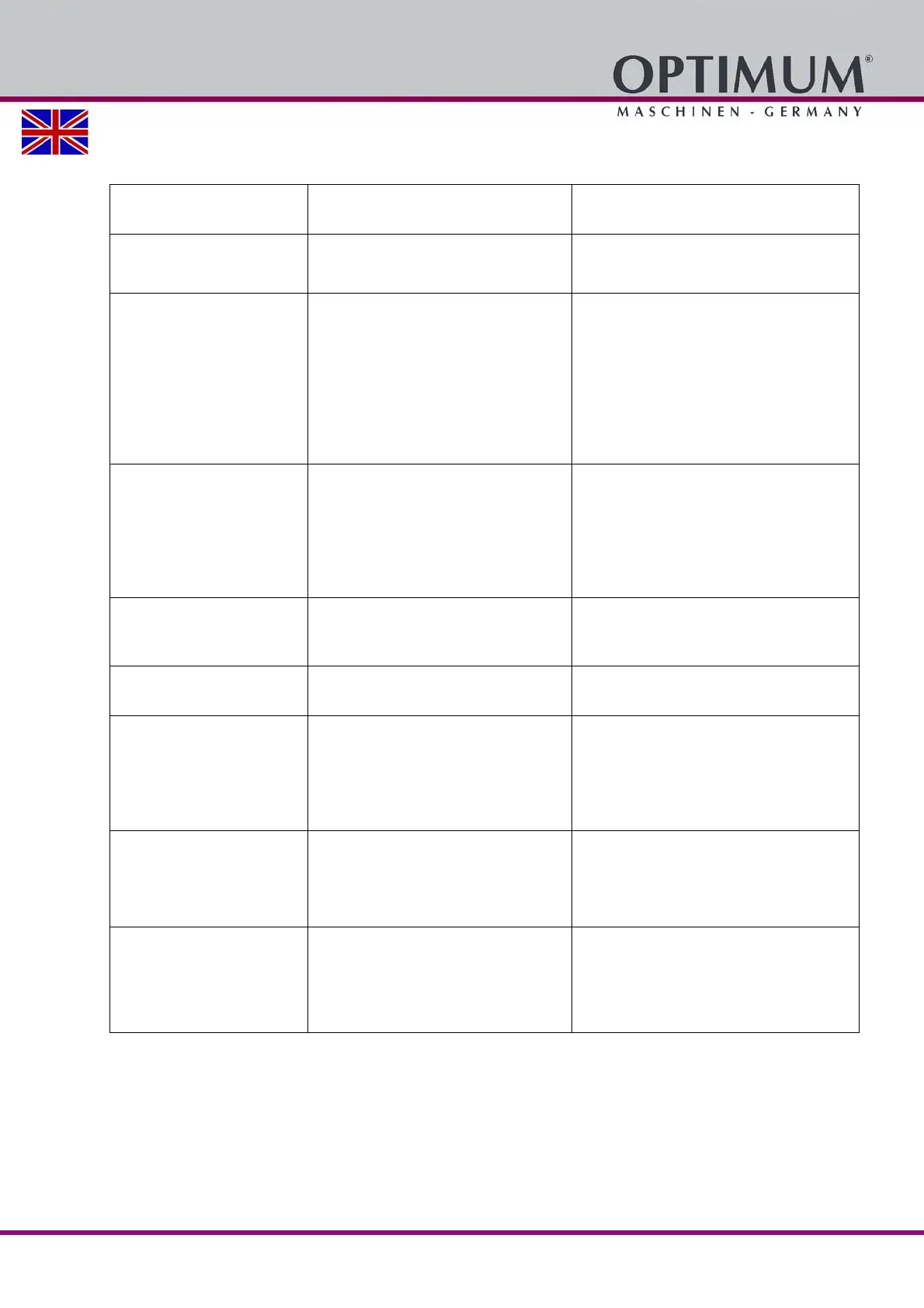

Malfunctions

Version 1.0.4 - 2020-08-04 101Translation of original instruction

MT60 EN

MT60_GB_6.fm

8 Malfunctions

Malfunction Cause/

possible effects

Solution

Noise during work. Spindle runs dry.

Tool blunt or incorrectly clamped.

Grease spindle

Use new tool and check clamping.

Tool "burnt". Incorrect speed.

Chips are not coming out of the

drilled hole.

Blunt tool.

Operating without cooling agent.

Choose a different speed, excessive

feed.

Retract tool more often during work.

Sharpen or replace tool.

Use coolant.

Tool running off-centre

or "hopping"

Tool deformed

Bearings worn down in the spindle

head.

Tool badly clamped.

Defective clamping chuck.

Replace the tool.

Have the bearings in the spindle head

replaced.

Clamp the tool properly.

Replace the clamping chuck.

Taper cannot be inserted

in quill.

Remove any dirt, grease or oil from

the internal conical surface of the

spindle sleeve or the taper.

Clean surfaces well.

Keep surfaces free from grease.

Motor does not start. Motor is wrongly connected.

Defective fuse.

Have it checked by qualified

personnel.

Motor is overheating and

there is no power.

Motor overloaded.

Insufficient mains voltage.

Motor wrong connected.

Reduce feed, disconnect if necessary

and have it checked by authorised

personnel.

Have it checked by authorised

personnel.

Precision of the work

deficient.

Heavy and unbalanced or

deformed work-piece.

Inexact horizontal position of the

work-piece holder.

Balance the piece statically and

secure without straining.

Adjust workpiece-holder.

Spindle bearing

overheating.

Bearing worn down.

Bearing pretension is too high.

Working at high speeds for a long

time.

Replace.

Reduce bearing clearance in the fixed

bearing.

Reduce feed rate.

Loading...

Loading...