25

1

2

"- LEVEL EXPERT- PELLENC POWER TOOL BATTERY" Workshop document

Issue 11/2016 ref. : DOCUMENT ATELIER_BATTERIE_EXP_OUTILS_PELLENC_V2_2016_ENG

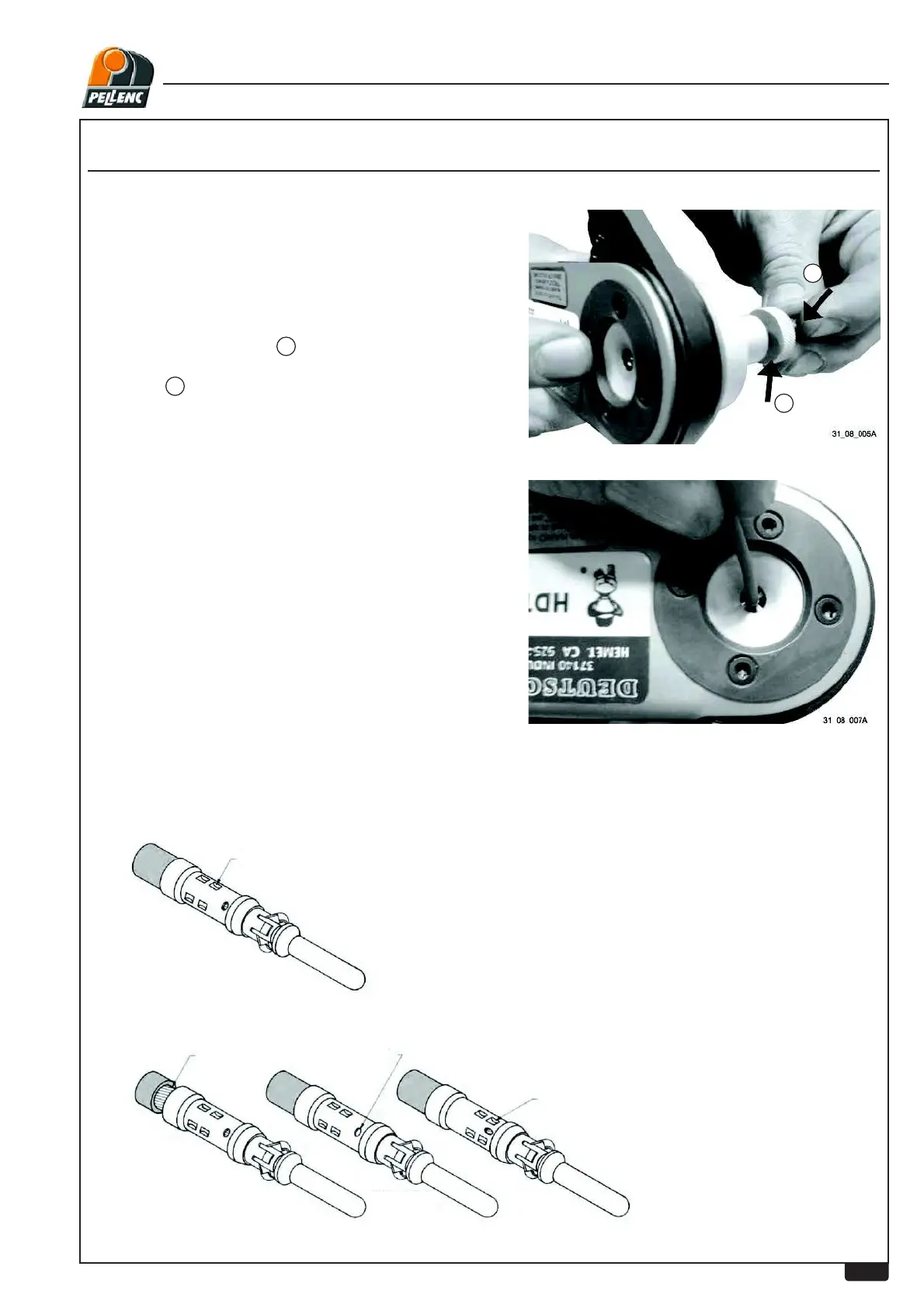

5- Turn the adjustment screw counter-clockwise to

increase the depth

of the lug to be crimped.

1

Then tighten the lock-nut clockwise to "lock" the

selection.

2

4- Adjust the mechanical stop so that the contact is

ÀXVKZLWKWKHRSHQLQJ

8- Inspect the crimp to validate the assembly; the wiremust not come out of the crimp when it is

pulled(Risk of contact splitting if crimped too hard).

6- Insert the wire fully into the lug to be crimped

7- &ULPSWKHZLUH¿UPO\XQWLOWKHFULPSLQJSOLHUVRSHQ

LEVEL 2 - USER'S TECHNICAL DEPARTMENT

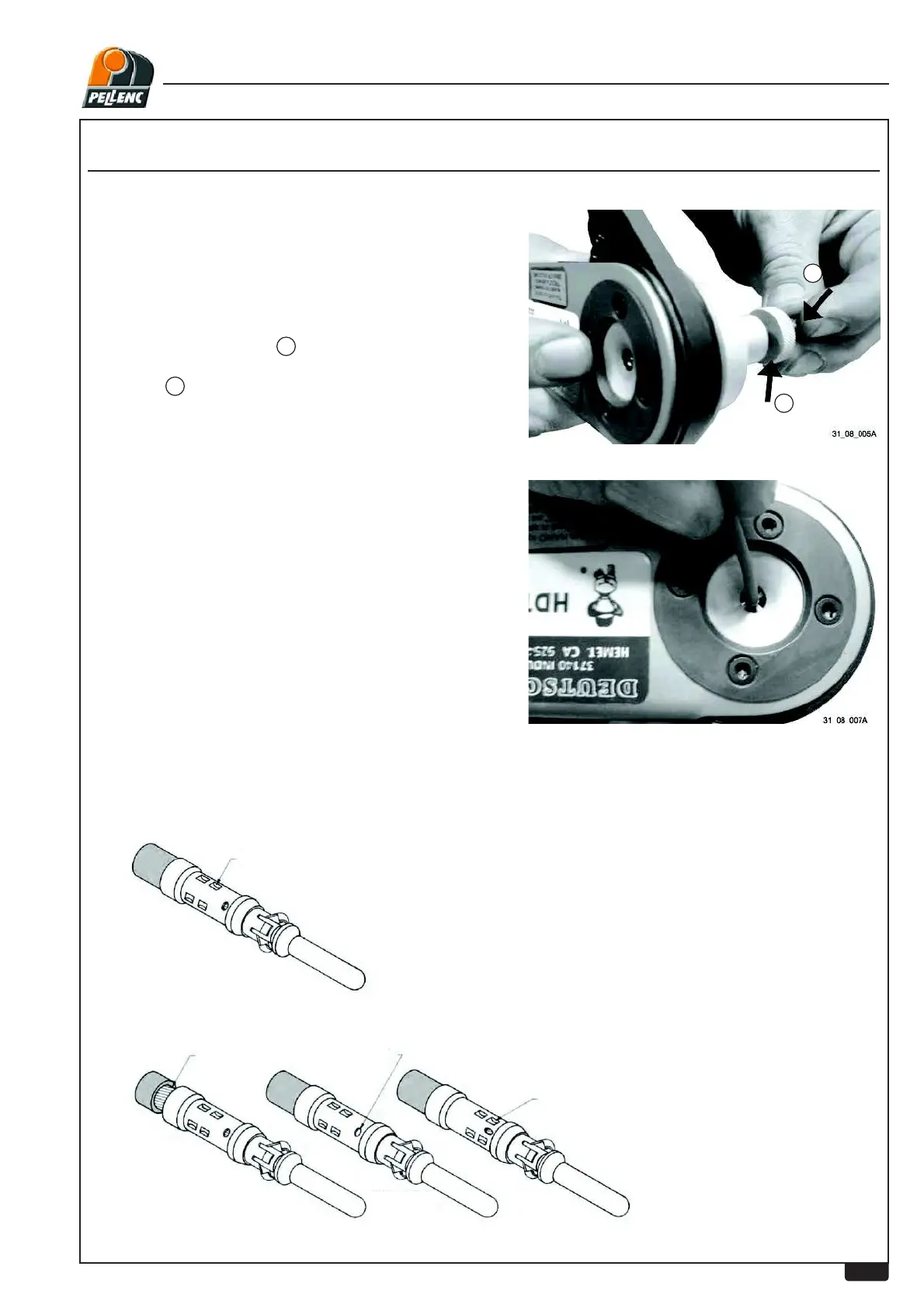

Correctly crimped contacts

Exa

mples of Crimping faults

Crimp to meet

recommended tensile

strength.

Strands visible beyond

insulation support.

Stripped part of the

wire too long.

Stripped part of the

wire too short.

Strands not visible

trough inspection hole

Crimp indents too close to

inspection hole

Crimp indents

incorrectly located

Loading...

Loading...