61

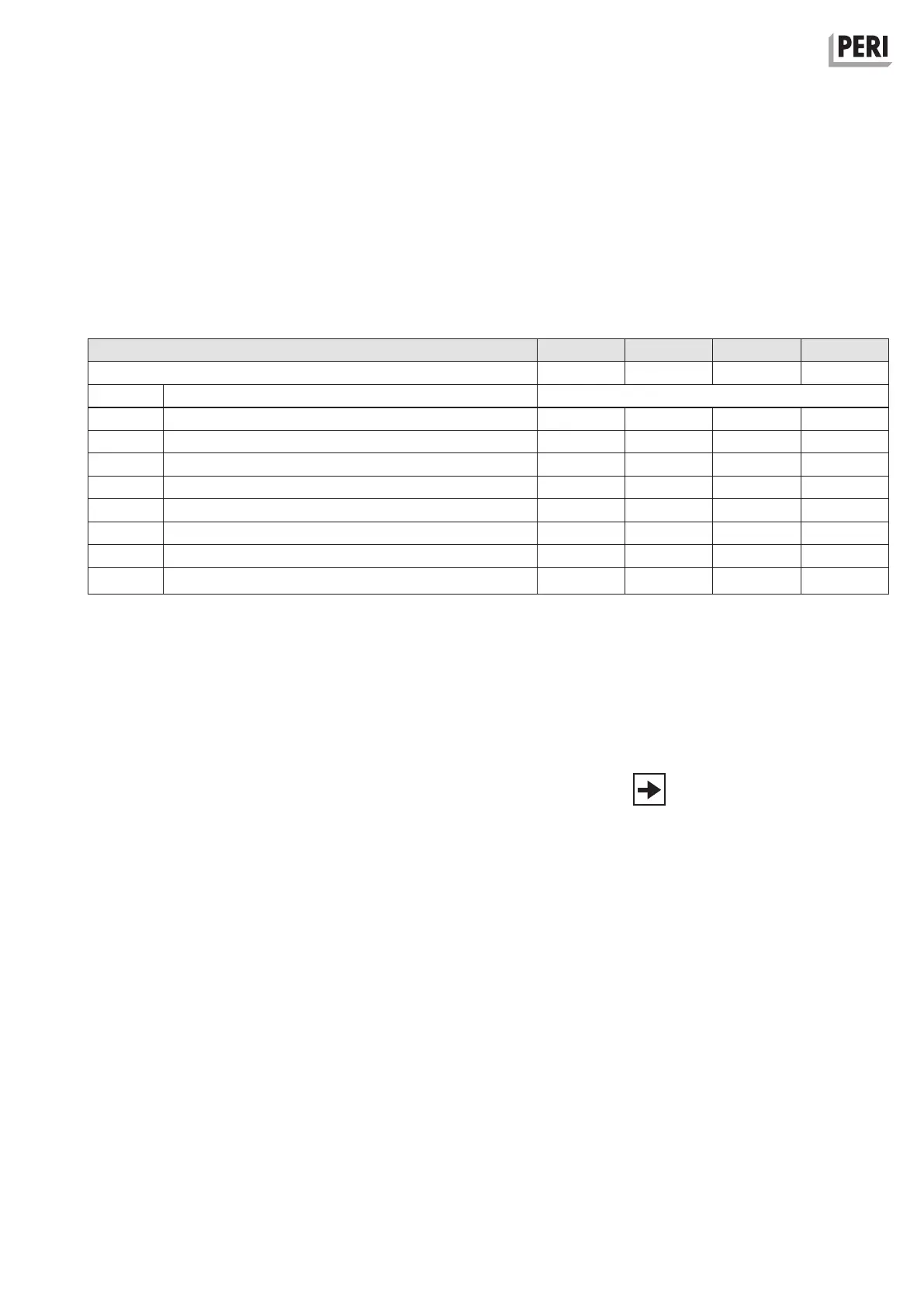

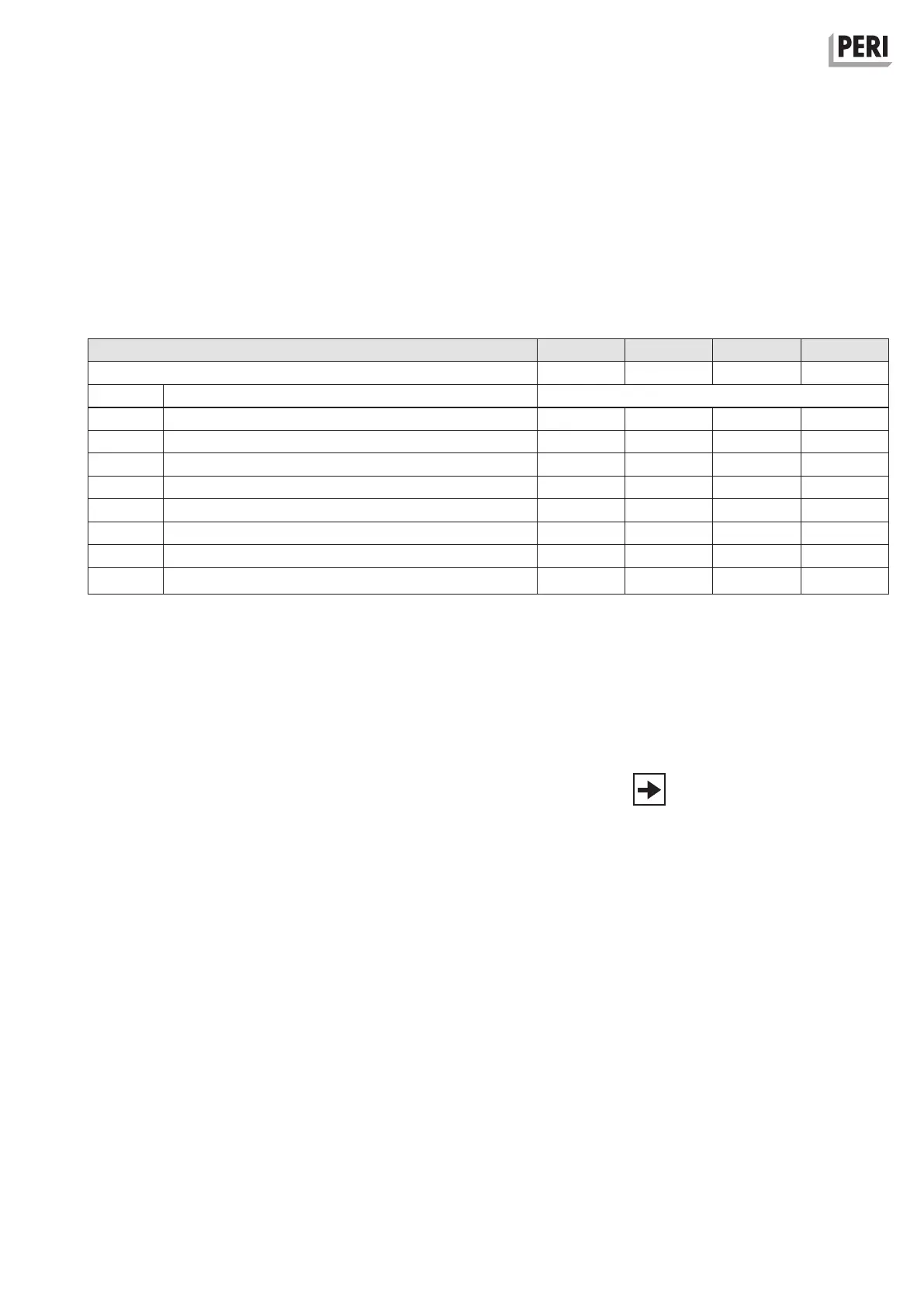

1.5 – 3.0 2.0 – 3.0 3.3 – 4.9 3.8 – 5.4

3.65 4.15 5.45 5.95

051430 1111

051420 1111

051410 1122

051450 1112

104132 ––1–

109105 1111

103718 2–2–

070711 1* –** 1* –**

Instructions for Assembly and Use – Standard Configuration

CB 160 Climbing Formwork

C1 Planning and work preparation

Ladder Access

Table 6

Parts list for ladder access

**

The ladders are attached to the top end of the sliding hatch cover.

The bottom ladder is attached using the ladder hook, and with the ladder base on timber at the lower end.

*

Screw ladder base tightly on decking of the finishing platform.

Working platform - finishing platform spacing [m]

Item no.

Sliding Hatch

Ladder 220/6

Ladder 180/6, galv.

Ladder Safety Cage 150, galv.

Concreting height [m]

Description

Parts List

Ladder Safety Cage 75, galv.

Ladder Base 30, galv.

Timber 10 x 10, L = 60 cm for assembly of Ladder Base 30

Ladder Hook, galv.

Assembly Drawings

At least the following points should

be featured in the assembly drawings:

– bracket spacing and bracing

– dimensions of the working and finish-

ing platform

– dimensions, arrangement and num-

ber of concreting and intermediate

platforms

– erection of girders and guardrails

– layout of end guardrail posts

– layout of lateral guardrails

– position of access ladders

– material requirements (parts list)

Drawings and plans

General Arrangement Drawings

At least the following points should

be featured in the general arrange-

ment drawings:

– position of the climbing anchor in the

plan view and sectional view

– which scaffolding platform is used on

which part of the building

– associated formwork and finishing

platform

– installation of wind bracing

– distance of finishing platform to the

working platform

– formwork and strongback connection

points

– timber brace position between the

strongbacks

– reference values for retraction dis-

tance during moving (see Table 1)

– possible special measures in case of

irregular concreting heights

– details of modifications

– material requirements (parts list)

Appropriate, easy-to-read as well as

sufficient drawings in both number and

format are to be made available to the

site management. The drawings are to

be created clearly and professionally in

the language of the country where con-

struction is taking place.

We recommend including a plan view

and sectional view of the scaffold as

well as an overview plan for positioning

purposes.

We recommend including a plan view

and a top view of the platform.

Loading...

Loading...