C-863 Mercury Controller MS205Equ Version: 2.0.0 3

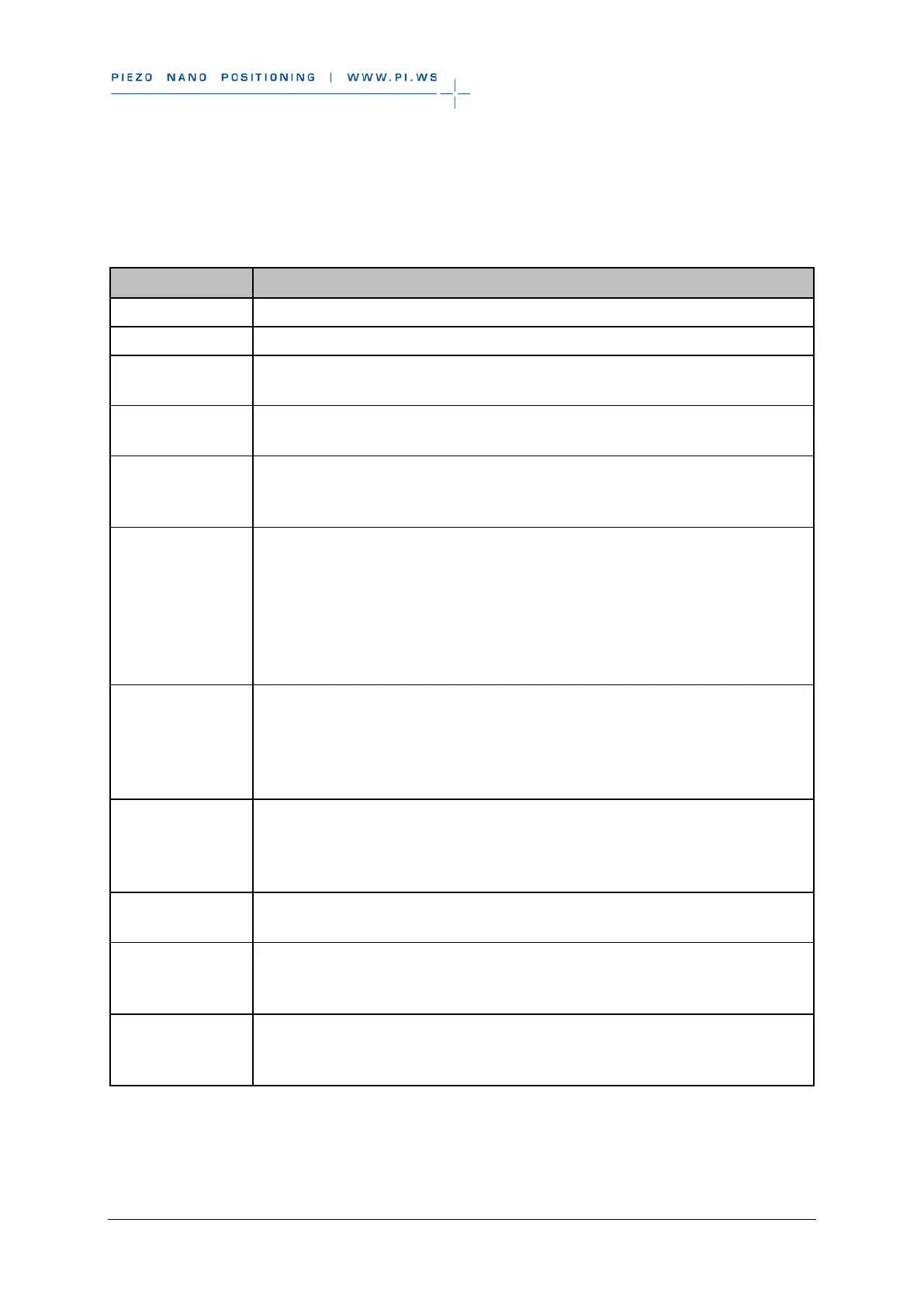

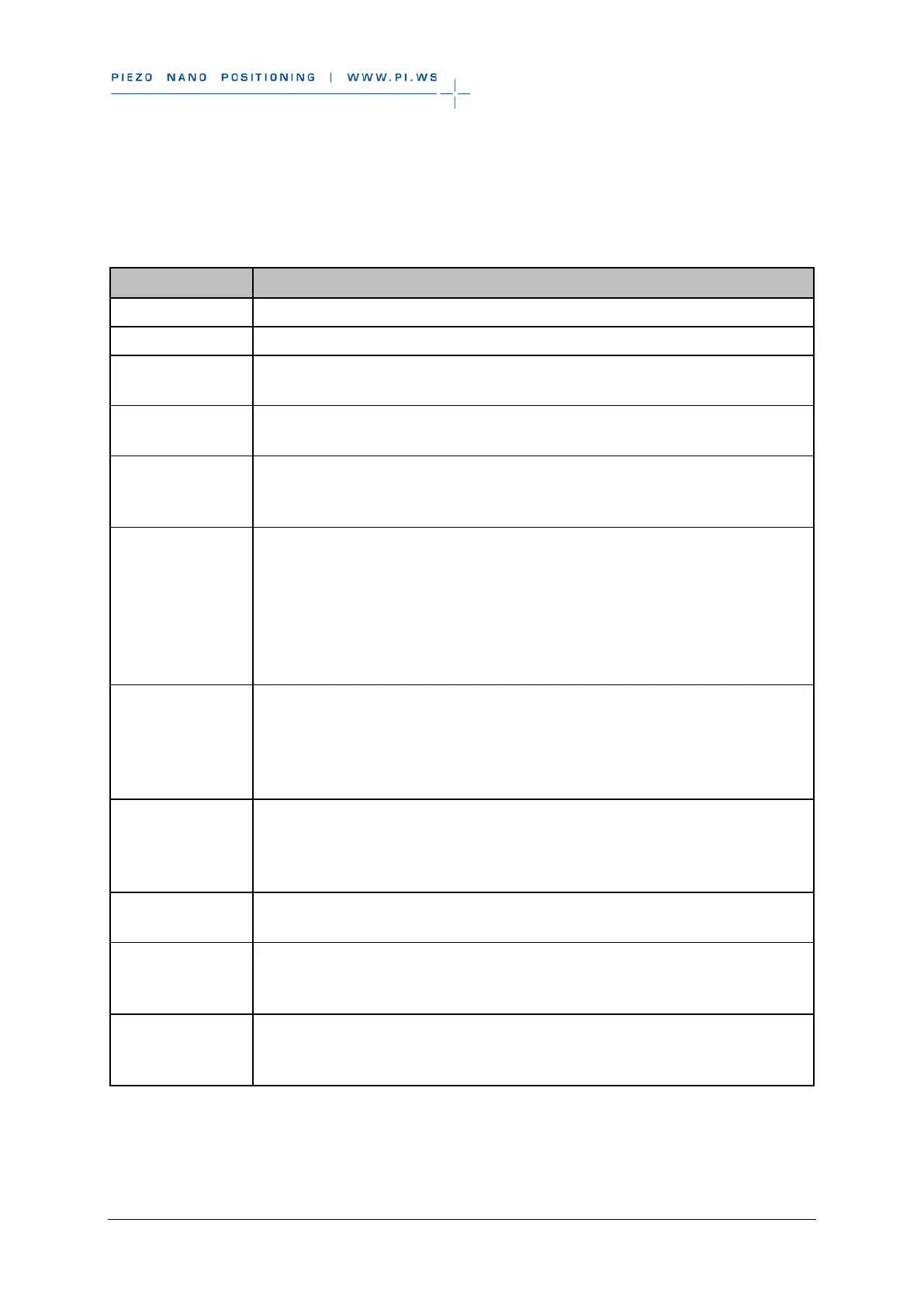

1.3 Definition

Term Explanation

PC software Software that is installed on the PC.

Firmware Software that is installed on the controller.

Volatile memory RAM module in which the parameters are saved when the controller is switched

on (working memory).

Non-volatile

memory

EEPROM memory chip (read-only memory), from which the default values of

the parameters are loaded to the volatile memory when the controller is started.

Axis Also referred to as "logical axis". The logical axis reflects the motion of the stage

in the firmware of the C-863. For stages that allow motion in several directions

(e. g. in X, Y and Z), each direction of motion corresponds to a logical axis.

Stage Mechanical system connected to the C-863. For stages having just one motion

axis the designation "axis" is synonymous with "stage". Stages that allow motion

in several axes are also designated as "multiaxis stages". For these stages, a

distinction must be made between the individual axes.

In this manual, actuators, i. e. drive components without a moving platform (e. g.

precision linear actuators), are designated as stages as well.

Daisy chain Wiring diagram by which one controller is connected to the next in sequence

(series connection principle). Here the first controller is connected directly to the

PC. The additional controllers are always connected to the ones that precede

them so that a chain is formed. The signal to and from a controller goes to the

PC via the previous controllers.

Incremental

position sensor

Sensor (encoder) for capturing changes of position or changes of angle. Signals

from the incremental position sensor are used for axis position feedback. After

switching on the controller a reference point definition must be performed before

absolute target positions can be commanded and reached.

Control value The control value is the input for the PWM converter of the C-863. The PWM

converter converts the control value into the PWM signal for the stage.

Dynamics profile Comprises the target position, velocity, and acceleration of the axis calculated

by the profile generator of the C-863 for any point in time of the motion. The

calculated values are called "commanded values".

GCS PI General Command Set; command set for PI controllers. Piezo drivers and

servo controllers can be operated conjointly with minimal programming effort

thanks to the GCS.

Loading...

Loading...