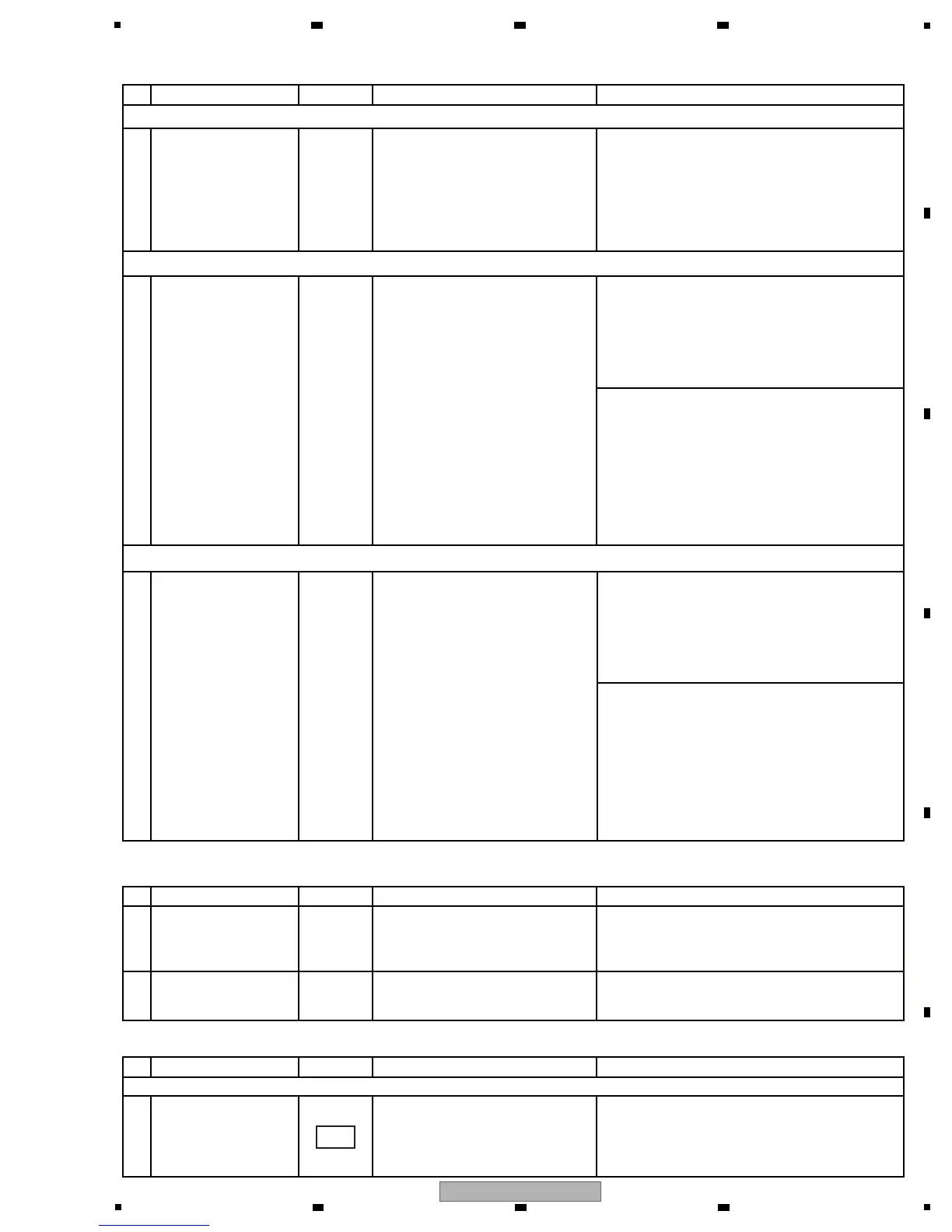

No. Waveform Items for check Causes and measuresPoints to be checked

-

Abnormal sound when the JOG dial is turned

1 JOG ASSY

-

The JOG dial turns too freely (The load on the JOG dial is outside the specified range.)

1 JOG ASSY

-

Resistance to turning the JOG dial is too strong (The load on the JOG dial is outside the specified range.)

1 JOG ASSY

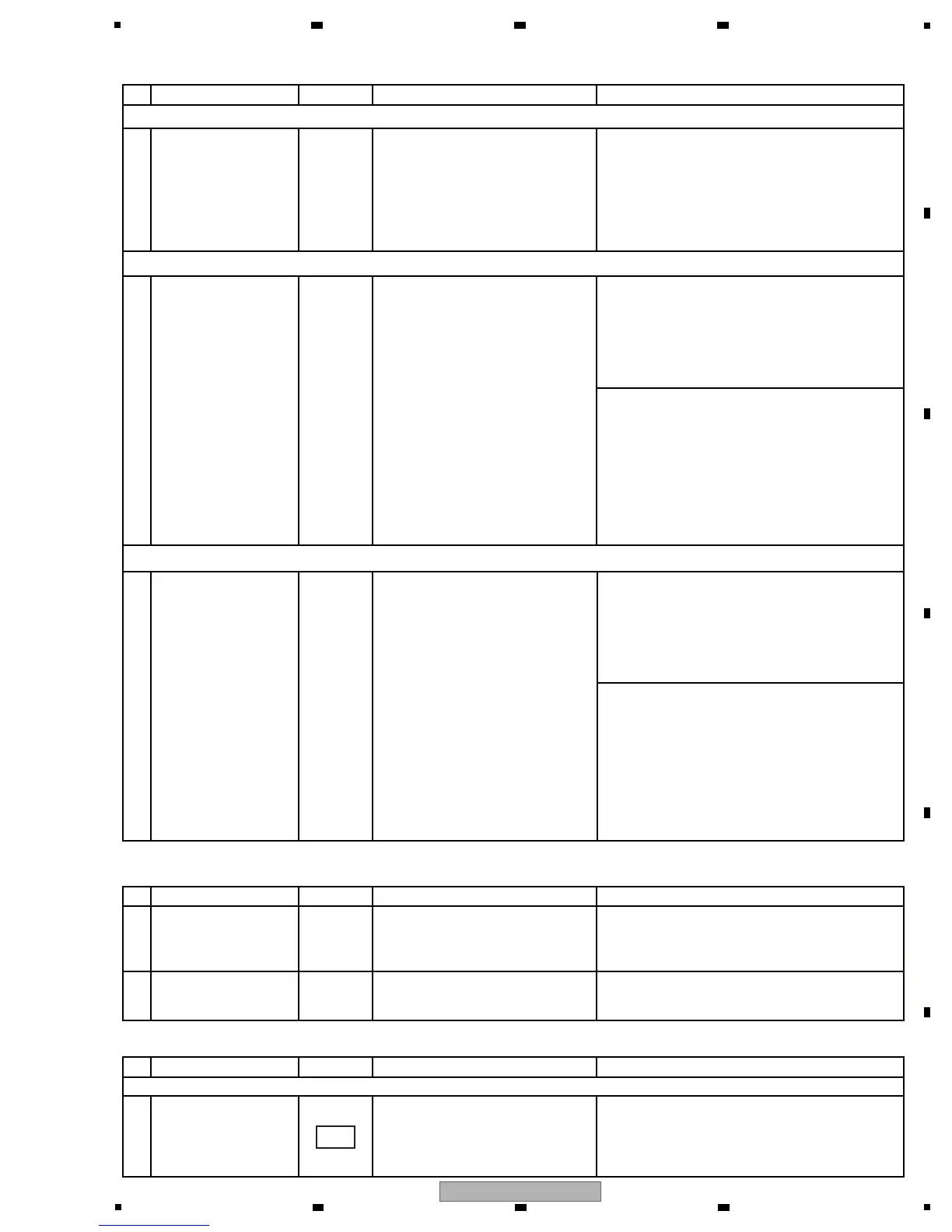

[3-7] Abnormality in operation of the rotary selector

(Turning or pressing of the rotary selector does not function.)

No. Waveform Items for check Causes and measuresPoints to be checked

1-

2-

CABLE

-

Either of the 2 types of gears have

scratches or burrs, or oil applied

to the gears is insufficient.

Check if the load on the JOG dial

is within the specified range,

according to [How to Measure]

in “8.1 CONFIRMATION MODE

AND ADJUSTMENT METHOD

FOR LOAD ON THE JOG DIAL.”

Check if the load on the JOG dial

is within the specified range,

accordingto [How to Measure]

in “8.1 CONFIRMATION MODE

AND ADJUSTMENT METHOD

FOR LOAD ON THE JOG DIAL.”

Check if the cables that connect

the RENC and NMAIN Assys are

securely connected and if there is

breakage in the cables.

If the problem is not resolved

even after the above-mentioned

measures are taken

Replace the gears and apply a little oil,

according to “1.6 REASSEMBLING OF THE

CONTROL UNIT.” After the gears are replaced,

oil must be applied. After that, check that the

load on the JOG dial is within the specified

range, according to “8.1 CONFIRMATION

MODE AND ADJUSTMENT METHOD FOR

LOAD ON THE JOG DIAL.”

If it is outside the specified range, the load on

the JOG dial may be too small or oil applied to

the dial is insufficient. Shift the position of the

adjustor plate according to [How to Adjust] in

“8.1 CONFIRMATION MODE AND ADJUST-

MENT METHOD FOR LOAD ON THE JOG

DIAL.”

If it is outside the specified range, the load on

the JOG dial may be too large or oil applied to

the dial is too much. Shift the position of the

adjustor plate according to [How to Adjust] in

“8.1 CONFIRMATION MODE AND ADJUST-

MENT METHOD FOR LO

AD ON THE JOG

DIAL.”

If a connection is loose, firmly connect the

cables.

If there is breakage, replace the cable.

Replace the rotary encoder (S2107).

During the above-mentioned adjustment, if the

position of the adjustor plate reaches the lower

limit, wipe off oil from the dial then reapply it,

according to “1.6 REASSEMBLING OF THE

CONTROL UNIT.” After the above-mentioned

adjustment is completed, check that the load

on the JOG dial is within the specified range,

according to “8.1 CONFIRMATION MODE

AND ADJUSTMENT METHOD FOR LOAD ON

THE JOG DIAL.”

During the above-mentioned adjustment, if the

position of the adjustor plate reaches the upper

limit, wipe off oil from the dial then reapply it,

according to “1.6 REASSEMBLING OF THE

CONTROL UNIT.” After the above-mentioned

adjustment is completed, check that the load

on the JOG dial is within the specified range,

according to “8.1 CONFIRMATION MODE

AND ADJUSTMENT METHOD FOR LOAD ON

THE JOG DIAL.”

Check the status with the auto

device diagnosis or the status

LEDs, or check the pulse wave-

form output at Pin 2 of the CPLD

(IC1700).

If the CENTER PANEL microcomputer (IC800)

is judged as NG, it has not been correctly

started up.See “[8] Auto Device iagnosis/Status

LEDs” in this section.

No. Waveform Items for check Causes and measuresPoints to be checked

[3-8] The keys do not function.

1

All the keys on the center area do not function.

-

151

Loading...

Loading...